Online roadbed compactness detection method based on machine vision

A technology of machine vision and detection methods, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as affecting roadbed performance, abnormal acceleration signals, and controversial positive correlation between acceleration amplitude and compaction degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0133] A kind of roadbed compactness online detection method based on machine vision of the present embodiment, its steps are:

[0134] (1) Set up a visual measurement system:

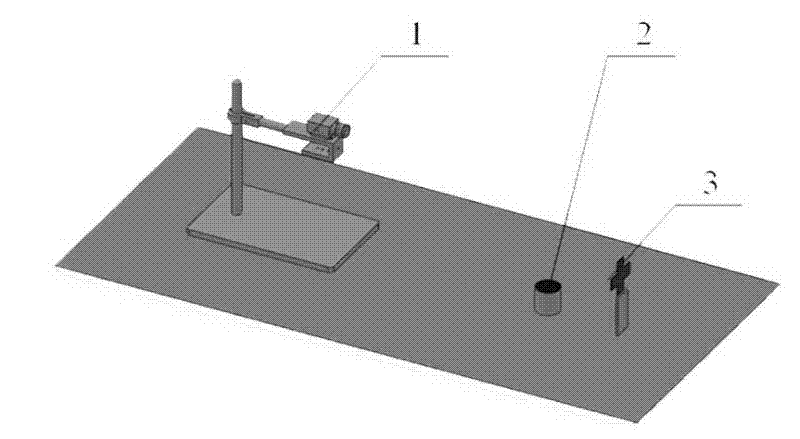

[0135] The compactness measurement of a compaction sampling point, the measurement system is composed of 1 CCD camera, 1 sampling mark feature point and 1 mark pile. Among them, the mark pile is divided into three layers, each layer is "ten" Font type, from left to right are respectively recorded as face □ 1 , face 2 And face □ 3 , the corner points of these three faces are marked as 1, 2, 3..., 12 in turn;

[0136] The marker piles in step (1) are arranged near the compaction sampling points, and the compaction degree sampling points and the marker piles are within the field of view of the CCD camera. 1 , face 2 And face □ 3 parallel to each other, facing 1 It is perpendicular to the construction road surface; the characteristic point of the compactness sampling mark is sprayed with circular ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com