Plasma facing experimental part with reference corner structure

A plasma and reference angle technology, applied in the direction of reducing greenhouse gases, instruments, nuclear reactors, etc., can solve the problems that affect the feasibility and accuracy of post-event analysis, and achieve the effect of avoiding surface inhomogeneity, convenient processing, and good contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

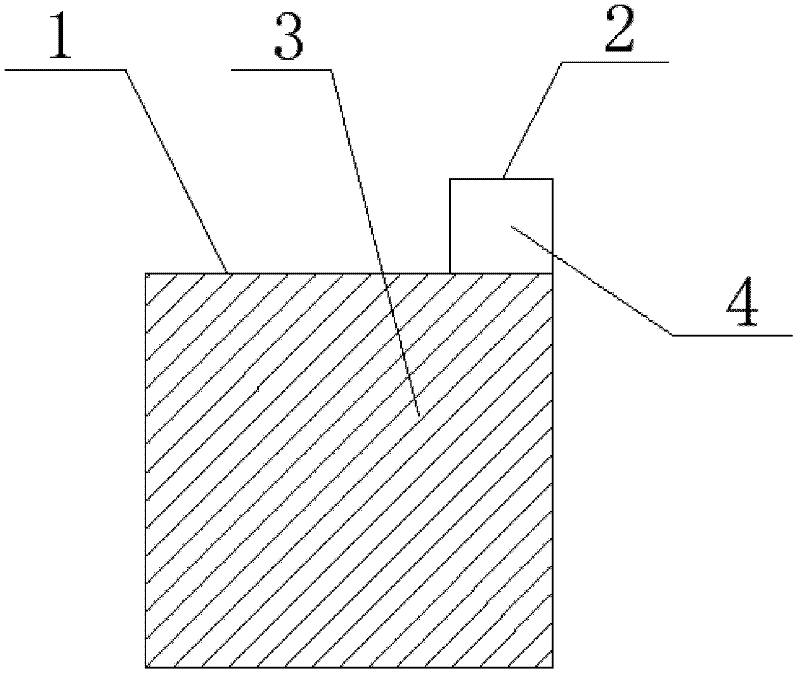

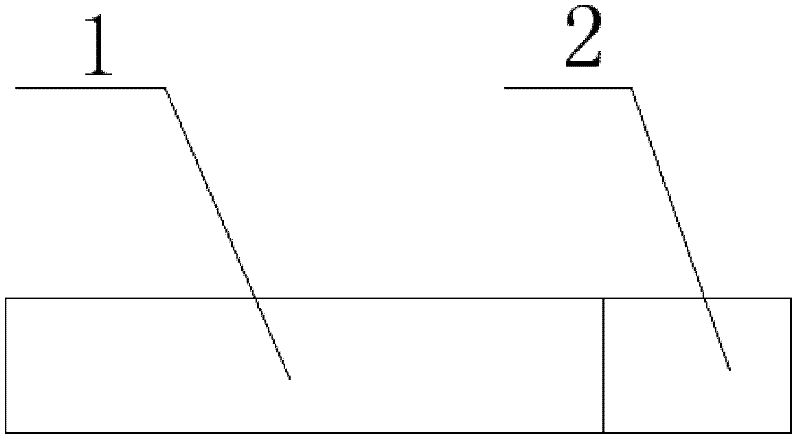

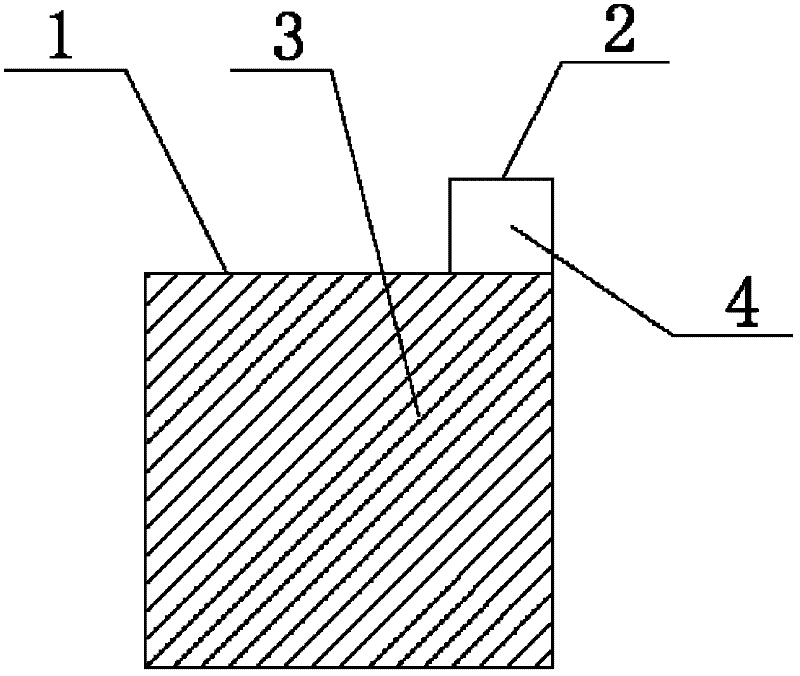

[0017] Such as figure 1 As shown, the present invention includes a test part 1 and a reference corner 2 arranged at one end of the test part 1 , and the reference corner 2 is a subtractive structure reserved on the test part 1 when the test part 1 is processed.

[0018] The material of the experimental component 1 is a plasma-facing material, preferably graphite, or molybdenum, or tungsten. During the experiment, the reference angle 2 is eliminated and embedded on the first wall of the tokamak device, and the surface is flush with the first wall.

[0019] One side of the reference angle 2 is used as the original surface 4, and one side of the experimental part 1 is used as the experimental surface 3. The same experimental marks are set on the original surface 4 and the experimental surface 3, and the surface part outside the experimental mark is the same as that in the experimental field. Other first walls or ordinary surfaces with the same divertor surface; the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com