Device for thinning multi-layer material and method for thinning to-be-detected sample

A multi-layer material and sample technology, applied in measurement devices, instruments, scanning probe microscopy, etc., can solve the problems of inability to accurately measure the etching depth, inability to accurately locate, and solve the problem of in-situ etching control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

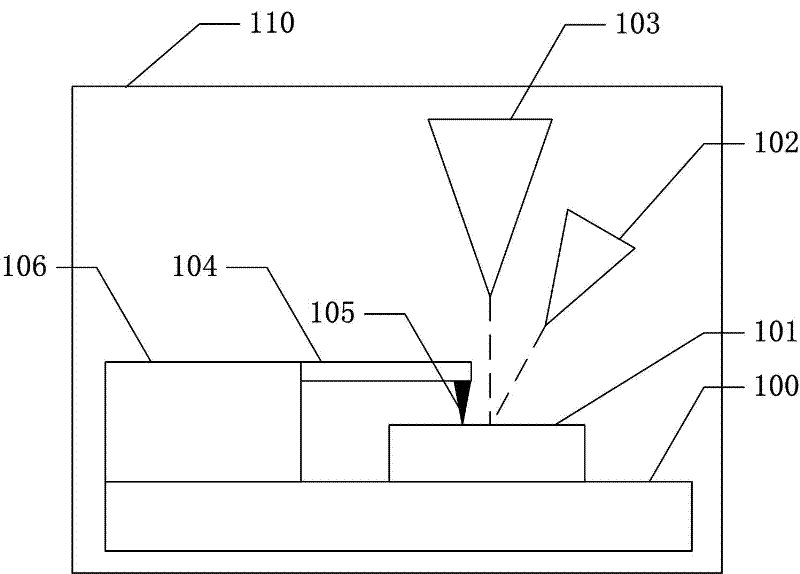

[0032] figure 1 Shown is a thinning device for a multi-layer material provided by the present invention, including a reaction chamber 110, an atomic force microscope, a focused ion beam device 103, an electron microscope 102 and a sample stage 100, and the sample stage 100, The focused ion beam device 103, the atomic force microscope and the electron microscope 102 are located in the reaction chamber 110; the sample stage 100 is used to place the sample to be tested; the atomic force microscope is used to measure the surface contact potential difference of the sample to be tested, including a conductive probe 105 and a microcantilever 104 and the control device 106; the focused ion beam device 103 is used to etch the sample to be tested; the conductive probe 105 is used to contact the sample to be tested and measure the contact potential difference between the conductive probe and the sample to be tested; the microcantilever 104, It is used to move the conductive probe 105; th...

Embodiment 2

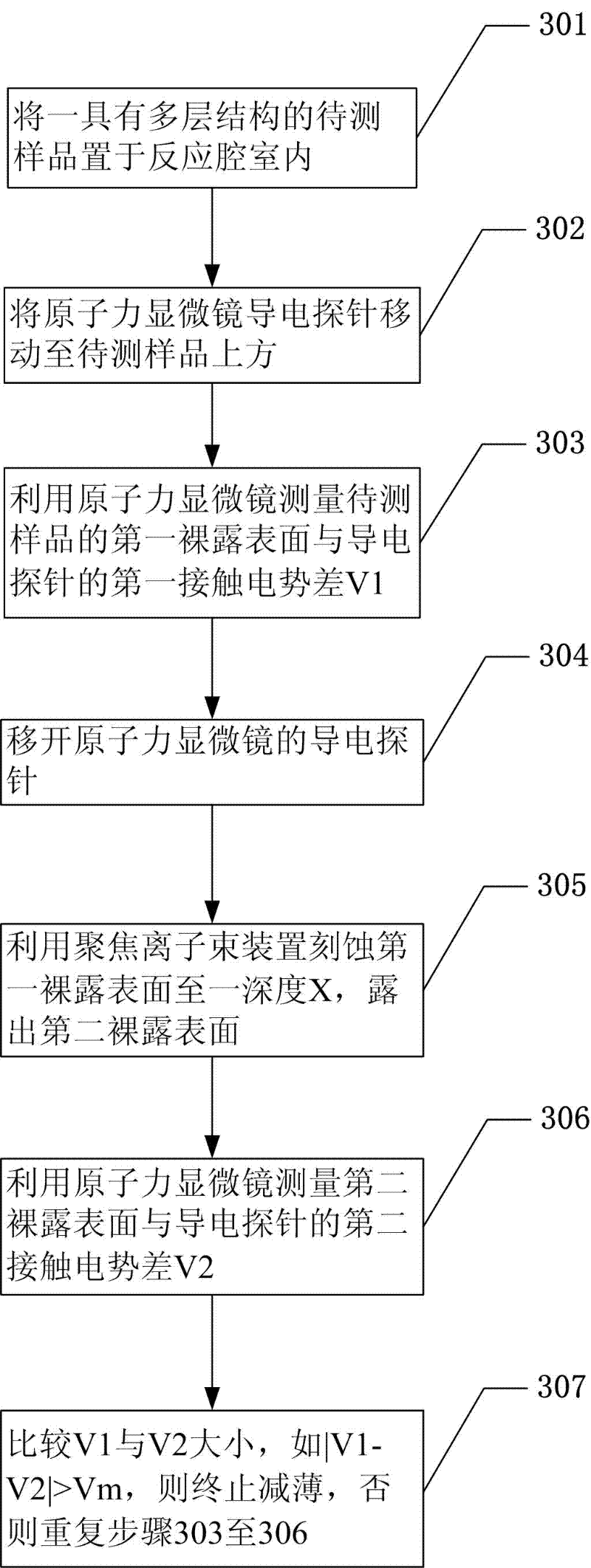

[0034] figure 2 Shown is the flow chart of the second step of the method embodiment of thinning the sample to be tested provided by the present invention, including: step 301, placing a sample to be tested with a multilayer structure in the reaction chamber; step 302, placing the conductive probe of the atomic force microscope The needle is moved above the sample to be tested; step 303, using the atomic force microscope to measure the first contact potential difference V1 between the first exposed surface of the sample to be tested and the conductive probe; step 304, removing the conductive probe of the atomic force microscope; step 305, using The focused ion beam device etches the first exposed surface to a depth X to expose the second exposed surface; step 306, uses an atomic force microscope to measure the second contact potential difference V2 between the second exposed surface and the conductive probe; step 307, compares V1 and V2 If the size is |V1-V2|>Vm, then the thin...

Embodiment 3

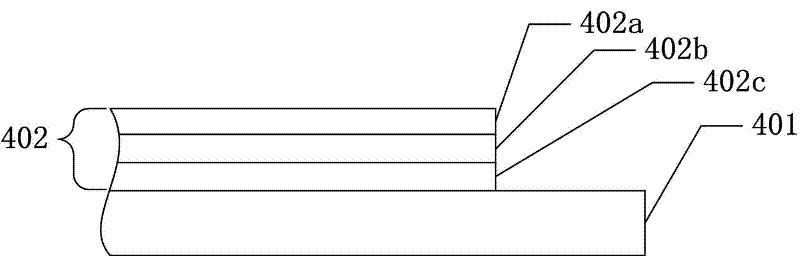

[0053] Figure 5 Shown is a schematic diagram of the structure of the sample to be tested in Embodiment 3 of the method for thinning the sample to be tested provided by the present invention. The sample to be tested 206 has a multilayer heterojunction structure, including p + GaAs layer 205, p + AlGaAs layer 204, p + GaAs layer 203, InGaAs layer 202, n - GaAs layer 201, n + GaAs layer 200 and n - GaAs substrate layer 210 . In addition, the layer thicknesses of the above-mentioned layer structures are 0.5 μm, 0.03 μm, 0.5 μm, 0.02 μm, 2 μm, and 0.5 μm, respectively.

[0054] The method for thinning the sample to be tested 206 includes: placing the sample to be tested 206 in a reaction chamber; imaging the designated etching region and the position of the conductive probe of the p+GaAs layer 205 of the sample through an electron microscope, and at the same time moving the microcantilever Conductive probe, under the guidance of the electron microscope image, move the condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com