Lithium-ion battery heat insulation device and control method thereof

A technology of heat preservation device and lithium battery, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as the limitation of the use environment temperature, and achieve the effect of solving the use environment temperature limitation, reducing the impact, and being easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

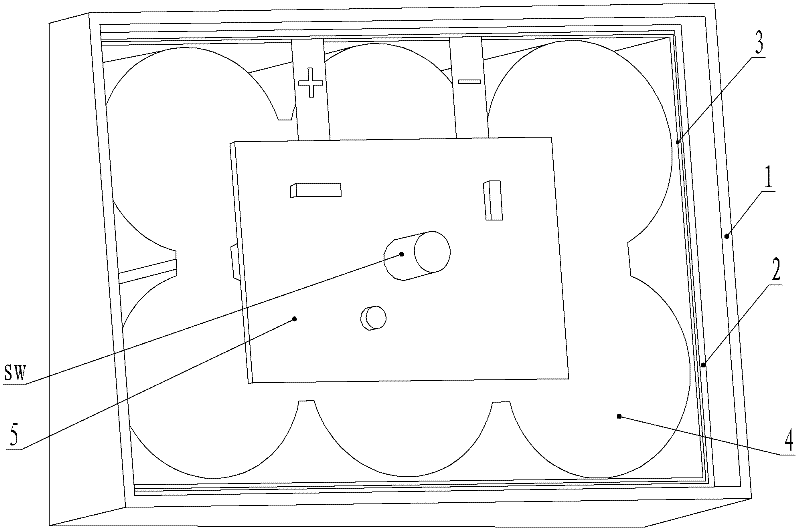

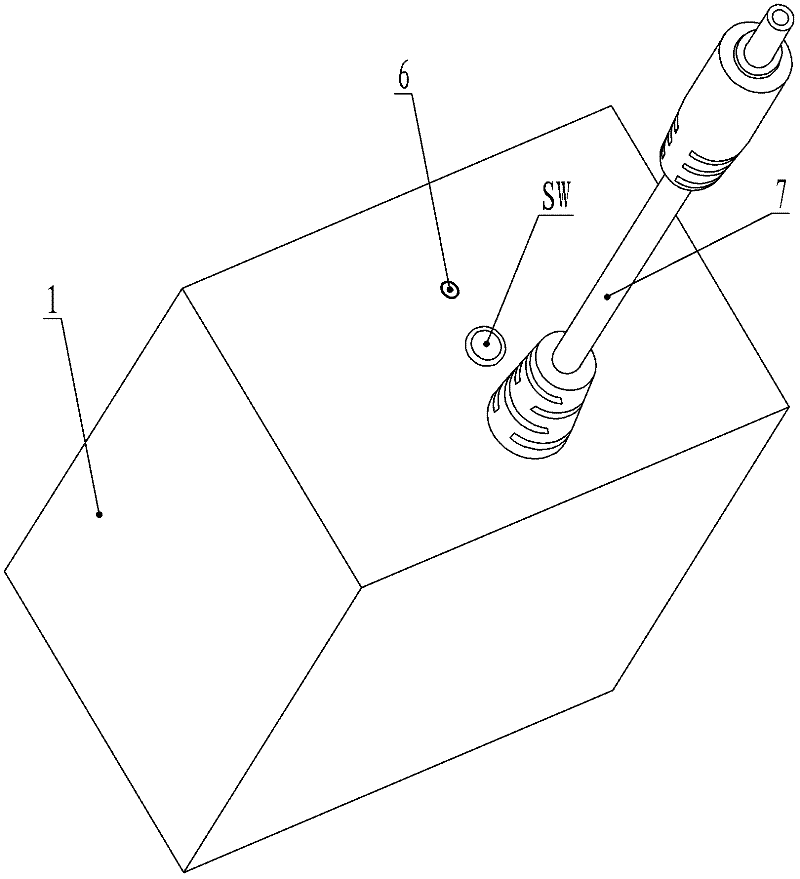

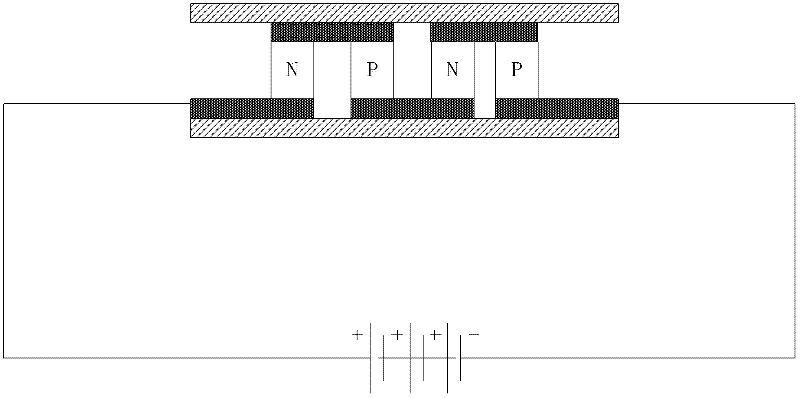

[0048] Figure 1~2 Shown the first embodiment of the present invention, the lithium battery heat preservation device in this embodiment, comprises the insulation case 1 that is used to place lithium battery, the heat preservation box 2 that is arranged in insulation case 1, is placed in heat preservation box 2 The lithium battery and the temperature regulating device 3 are also provided with a temperature control circuit in the insulating casing 1, the temperature control circuit is powered by the lithium battery and is used to automatically control the ambient temperature of the lithium battery.

[0049] The insulating casing 1 is a box body made of insulating material that plays a protective and supporting role. Preferably, the box body material is a material with good heat insulation effect, high strength, and good insulation performance, such as plastic, Plastic, resin, etc. The inside of the box / insulation box 1 is further provided with a heat insulation box 2, and the t...

no. 2 example

[0056] The second embodiment of the present invention provides a lithium battery heat preservation method. This method uses the lithium battery heat preservation device in the first embodiment. When the lithium battery or lithium battery pack needs to be used in an extreme temperature environment, first open the insulating casing 1 The manual main switch SW on the box cover makes the temperature control circuit start to work, at this time the LED indicator lights up; then set the temperature limit point of the temperature control automatic switch module Kt, the temperature limit point can be set to one or more, For example, it is set to 5°C and 30°C, and the normal working temperature is between 5°C and 30°C.

[0057] When the temperature detection module Rt detects that the temperature of the lithium battery is higher than 30°C, the temperature control automatic switch module Kt automatically controls the thermoelectric cooling sheet in the temperature control device 3 in the ...

no. 3 example

[0062] The second embodiment of the present invention provides a lithium battery heat preservation method. The method uses the lithium battery heat preservation device in the first embodiment. The temperature limit point of this method can be set to more, for example, the first low temperature threshold is set to 5°C. and the second low temperature threshold of 0°C, the first high temperature threshold of 30°C and the second high temperature threshold of 35°C, a comparator and a control chip are also arranged in the temperature control circuit. When the manual main switch SW on the cover of the insulating box 1 is turned on, the temperature control circuit starts to work, and the LED indicator lights up at this time; when the temperature detection module Rt detects that the temperature of the lithium battery is higher than the first high temperature threshold of 30°C, The temperature control automatic switch module Kt automatically controls the thermoelectric cooling sheet in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com