Ultrasonic atomization dust-settling nozzle for underground coal mine

An ultrasonic atomization and nozzle technology, applied in dust prevention, mining equipment, injection devices, etc., can solve problems affecting normal production, water accumulation on the working surface, and large particle size of atomizing nozzle water mist, so as to improve atomization The result of efficiency and power, easy cleanup, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

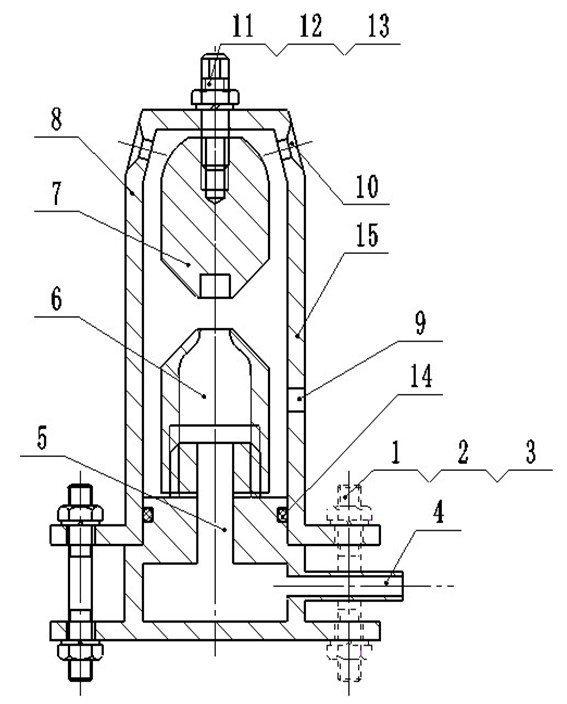

[0036] The air outlet of the vortex whistle 5 is threadedly connected with the whistle nozzle 6, and the air outlet thread of the vortex whistle 5 is screwed to the bottom. The resonant chamber 7 of the whistle is connected to the nozzle body 8 through the adjusting bolt 11, and at the same time, a layer of rubber is applied to the thread of the adjusting bolt 11, and the adjusting bolt 11 and the whistle resonating chamber 7 are bonded into a whole, and the thread is screwed to the bottom. Can. Then the nut 12 and the spring washer 13 are connected with the adjusting bolt 11 , and the nut 12 and the spring washer 13 are glued on the nozzle body 8 . The purpose of doing this is to ensure that the diameter of the nozzle constriction of the whistle nozzle 6 is consistent with the distance between the whistle nozzle 6 and the whistle resonant cavity 7, so as to achieve the best atomization effect; The main body 8 forms a whole. By rotating the adjusting bolt 11, the distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com