Alternating and direct current and voltage signal detection device for double-wire welding

A technology of voltage signal and detection device, applied in the direction of measuring current/voltage, measuring device, welding equipment, etc., can solve the problems of system real-time performance, low reliability, insufficient system application scope, single software and hardware functions, etc. High-speed and accurate recording and storage, easy and fast operation, powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described and illustrated in further detail below in conjunction with the accompanying drawings.

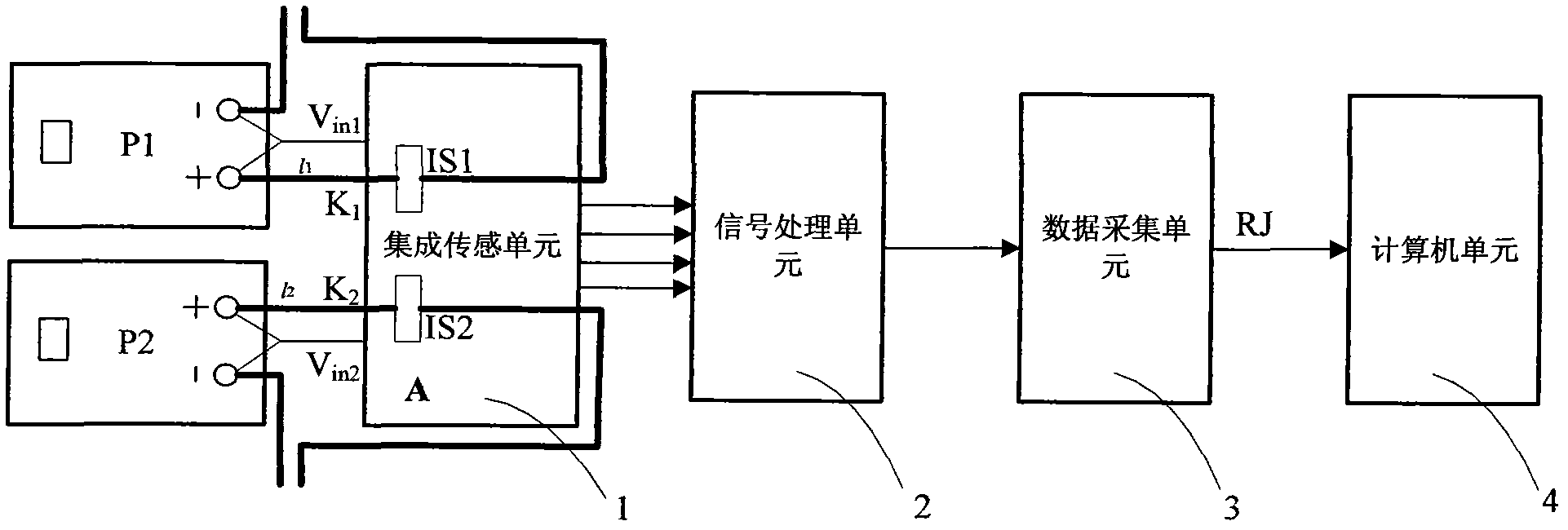

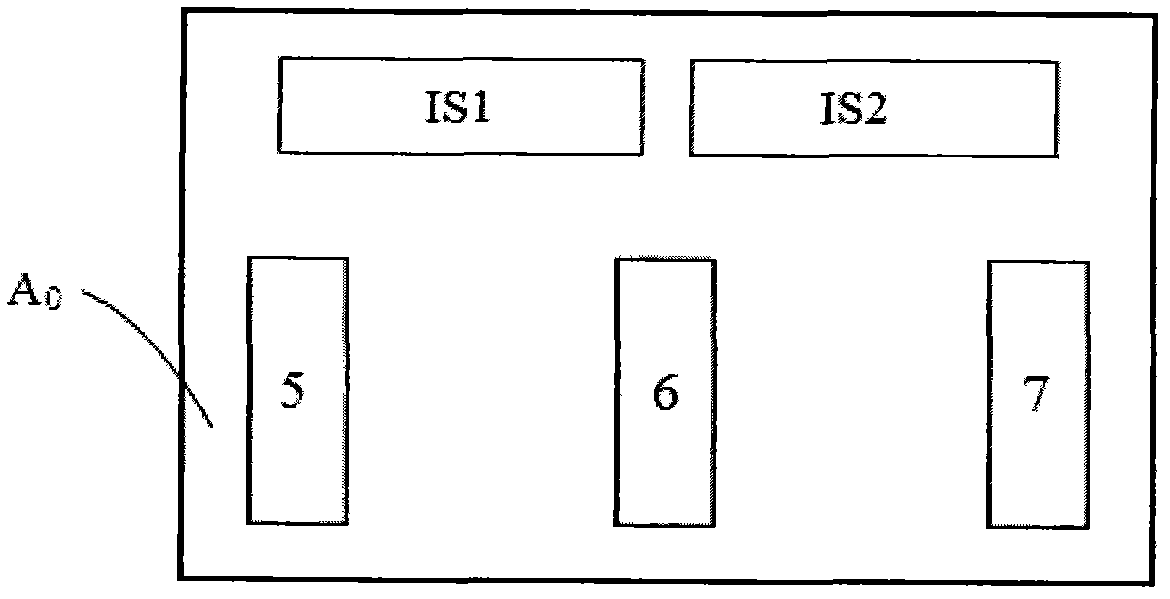

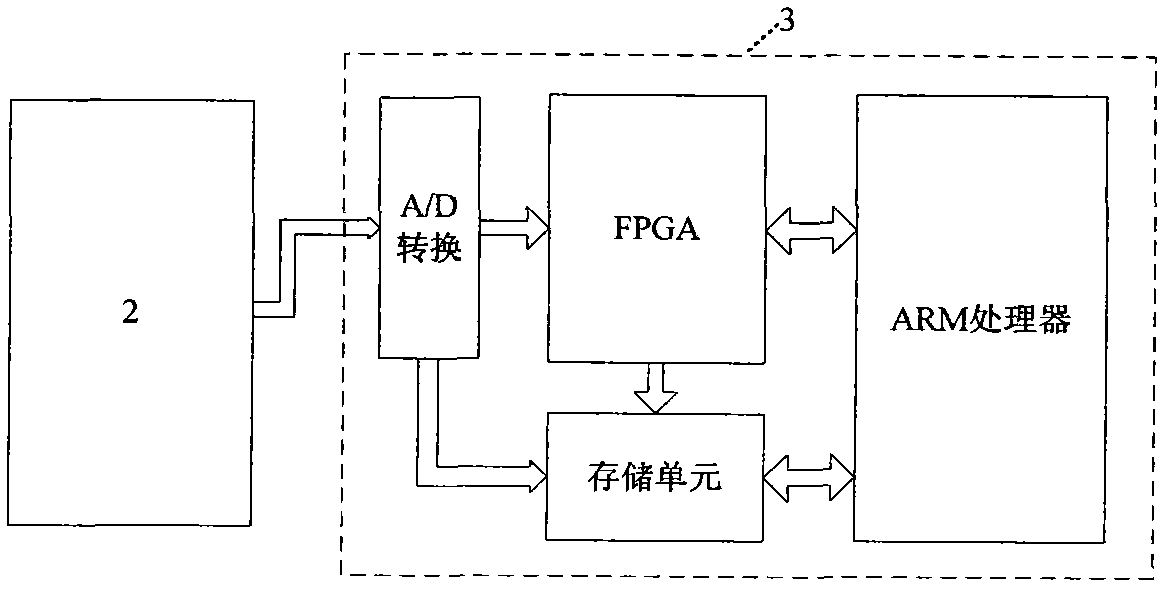

[0027] figure 1 It is a structural block diagram of the AC / DC current and voltage signal detection device for double-arc welding of the present invention. The detection device includes an integrated sensing unit 1 , a signal processing unit 2 , a data acquisition unit 3 and a computer unit 4 . The first arc welding power supply P 1 and the second arc welding power source P 2 Used to supply power to the twin welding wires separately. Among them, the first and second input terminals V of the integrated sensing unit 1 in1 , V in2 Correspondingly with the first arc welding power source P 1 and the second arc welding power source P 2 The positive and negative output ports of the two arc welding power sources are connected to realize the measurement of the output voltage of the two arc welding power sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com