Integral impeller blade semi-finishing method for removing residual stress with aid of laser

A technology of residual stress and integral impeller, which is applied to components of pumping devices for elastic fluids, manufacturing tools, liquid fuel engines, etc., can solve problems such as micro-cracks on the blade surface and blade deformation, and achieve the reduction of micro-cracks and control Effect of deformation, good stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

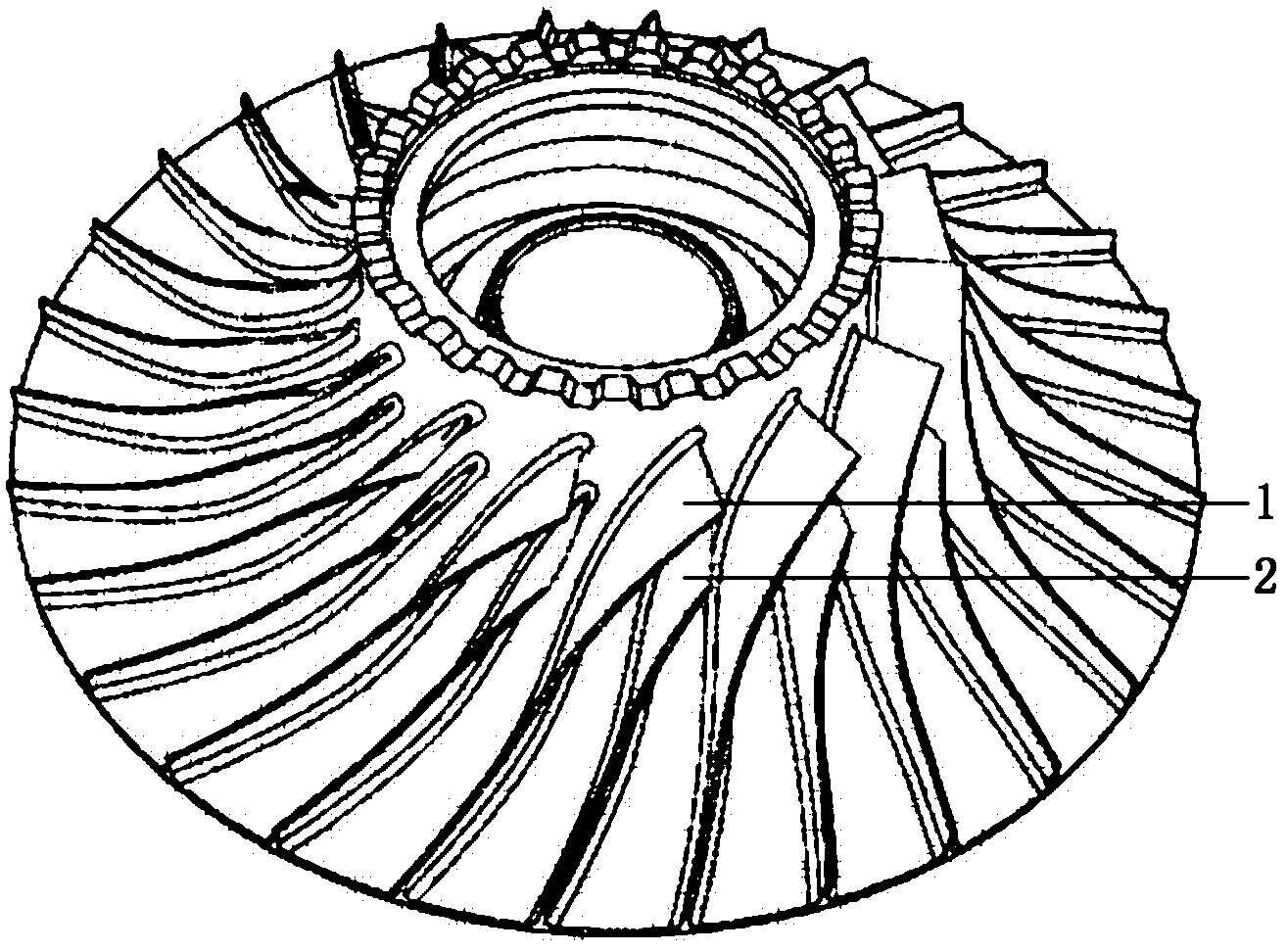

[0021] The present invention is a laser-assisted processing method for removing stress of a half-open centrifugal integral impeller, and the processed integral impeller is as follows: figure 1 As shown, arc-shaped long blades 1 and short blades 2 are provided on the wheel surface. The material of the integral impeller is nickel-based superalloy, the blade thickness is 0.5-2.5cm, the curved surface is smooth, and there is no stress concentration.

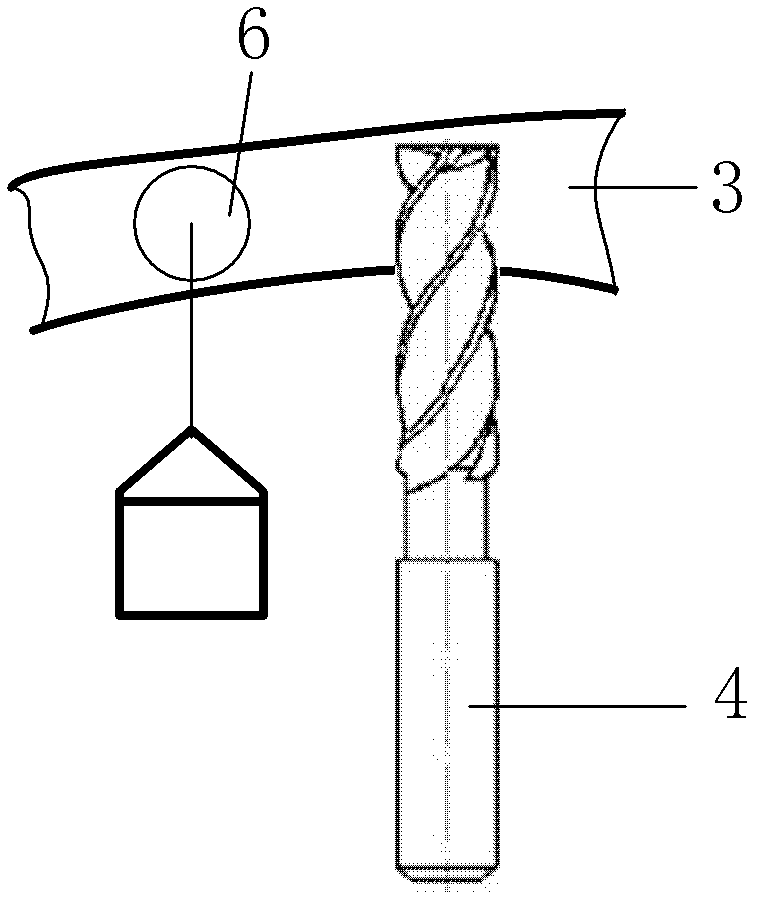

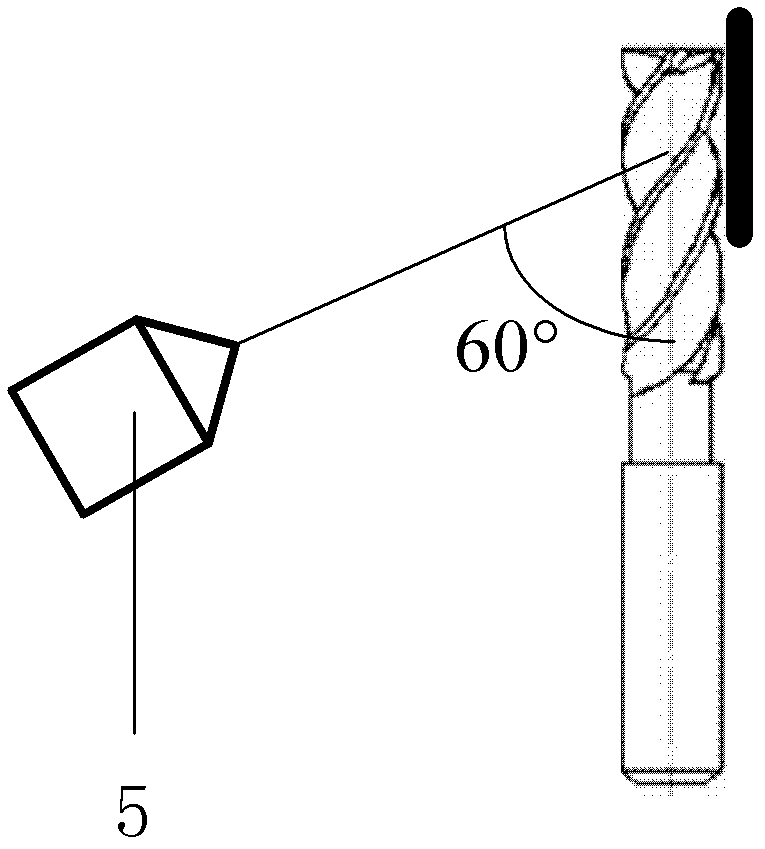

[0022] The content of the semi-finishing method of the integral impeller blade with laser-assisted removal of residual stress is: after the heat treatment process and before the conventional semi-finishing process, the surface of the impeller blade is subjected to laser shot peening treatment with a pulsed laser beam, and then the The impeller blade surface is milled to remove the surface deformation layer caused by laser shot peening treatment. In this way, the residual compressive stress and the residual tensile stress produced by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com