Cooling device for diamond-wire cutting system

A technology for cooling devices and diamond wires, which is applied to fine working devices, knives of sawing machine devices, grinding/polishing safety devices, etc., and can solve problems such as the inability of coolant to enter, limited cooling effect of diamond wires, and detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

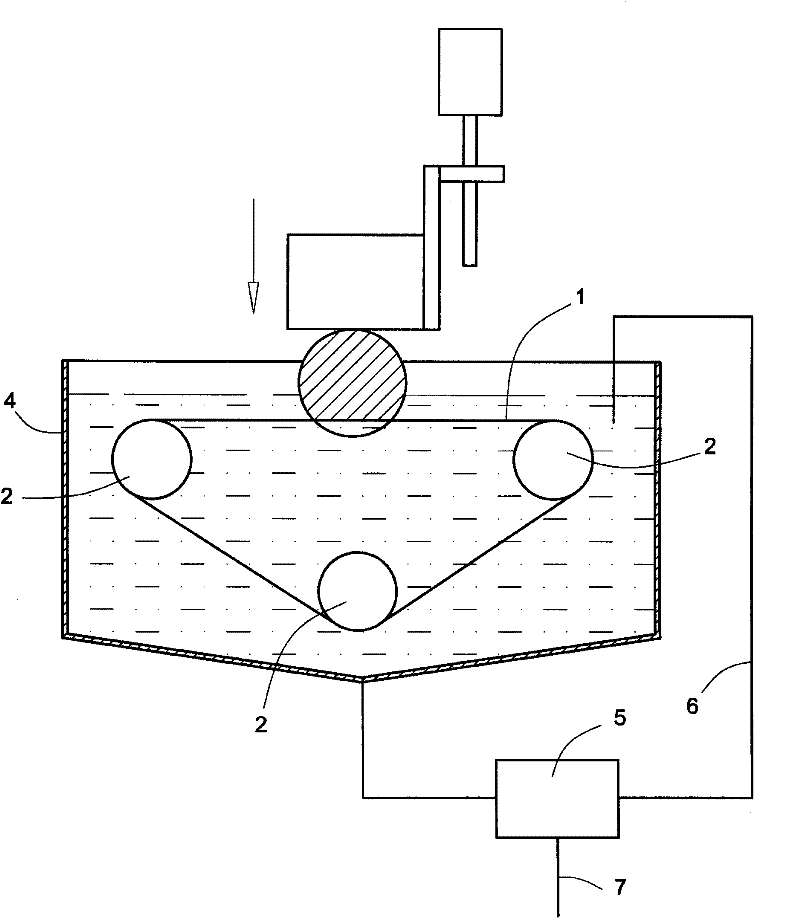

[0028] Please refer to image 3 As shown, the cooling device for diamond wire cutting of the present invention includes a liquid tank 4, and a choke space that can temporarily stagnate and accumulate cooling liquid is formed in the liquid tank 4, and a saw that diamond wire 1 is provided for sawing The cut part is submerged in the cooling liquid.

[0029] Again, a separation collector 5 is connected under the liquid tank 4, and then a cooling liquid recovery pipe 6 is set up on the separation collector 5 to return to the liquid tank 4, and then it is placed under the separation collector 5. A debris recovery pipe 7 is established.

[0030] Therefore, the cutting part of the hard and brittle material to be sawed and the sawing part of the diamond wire 1 are kept immersed in the cooling liquid at any time, so that the heat generated when the hard and brittle material is cut and the sawing debris, With the flow of coolant, it can be dissipated and removed very quickly, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com