Method for preparing single/double walled carbon nano tube structure with small size of tube bundle

A technology of double-walled carbon nanotubes and single-walled carbon nanotubes, applied in the field of preparation of monodisperse single/double-walled carbon nanotubes, can solve the problems of low efficiency, short single single/double-walled carbon nanotubes, and limited single/double-walled carbon nanotubes. Double-walled carbon nanotube device preparation and performance issues, to achieve the effect of high crystallinity of the sample

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

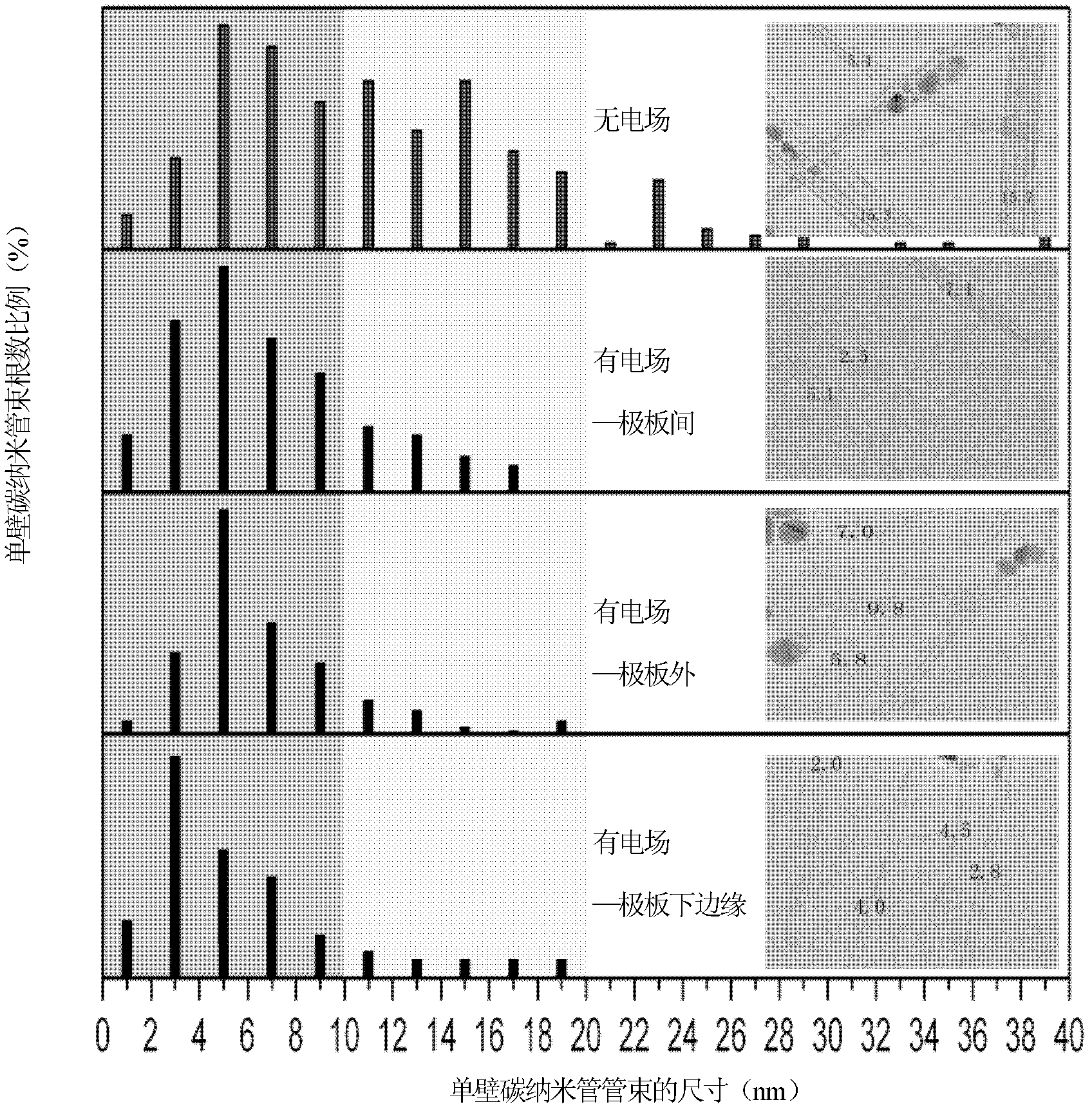

[0020] The mixed powder of graphite, 2.0atm.% catalyst (molar ratio: Fe: Co: Ni=1: 1: 5) and 0.5 atm.% iron sulfide growth promoter is put into the anode graphite disk hole and compacted, The cathode is a graphite rod with a diameter of 10mm. The reactor is filled with 32KPa hydrogen, the arcing current is 120A DC, and the shortest distance between the two electrodes is 2mm and the included angle is 30°. The electric field is applied in situ between the two electrodes. The electric field strength is 250V / cm. A comparative experiment was carried out without / with an applied electric field, and the transmission electron microscope photos and the statistical histograms of the tube bundle size distribution of the obtained single-walled carbon nanotube samples in various parts of the cavity are as follows: figure 1 shown. When no electric field is applied, the size distribution of single-walled carbon nanotube bundles in the cavity is 47% between 0-10nm, about 42% between 10-20nm, ...

Embodiment 2

[0022] The difference from Example 1 is:

[0023] The mixed powder of graphite, 4.0atm.% catalyst (molar ratio: Fe: Co: Ni=1: 1: 5) and 4.0atm.% iron sulfide growth promoter is put into the anode graphite disc hole and compacted, The cathode is a graphite rod with a diameter of 10mm. The reactor is filled with 67KPa helium, the arcing current is 200A DC, and the shortest distance between the two electrodes is maintained at ~2mm and the included angle is ~40°. An electric field is applied in situ between the two electrodes. The electric field strength is 125V / cm. A comparative experiment was carried out without / with an applied electric field, and the transmission electron microscope characterization and the statistics of the size distribution of the tube bundles were carried out for the single-walled carbon nanotube samples in various parts of the obtained cavity. Statistical results show that 42.2% of the single-walled carbon nanotube bundles in the cavity are distributed bet...

Embodiment 3

[0025] The difference from Example 1 is:

[0026]The mixed powder of graphite, 4.0atm.% catalyst (molar ratio: Fe: Co: Ni=1: 2: 0.4) and 0.8atm.% iron sulfide growth promoter is put into the anode graphite disc hole and compacted, The cathode is a graphite rod with a diameter of 10mm. The reactor is filled with 32KPa helium gas, the arcing current is 150A DC, and the shortest distance between the two electrodes is maintained at ~2mm and the included angle is ~40°. An electric field is applied in situ between the two electrodes. The electric field strength is 200V / cm. A comparative experiment was carried out without / with an applied electric field, and the TEM characterization and bundle size distribution statistics of the obtained double-walled carbon nanotube samples in various parts of the cavity were carried out. Statistical results show that when no electric field is applied, the size distribution of double-walled carbon nanotube bundles in the cavity is 48.4% between 0-10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap