Novel high-efficiency anaerobic treatment device for soybean protein wastewater

A soybean protein wastewater and processor technology, applied in the field of anaerobic processors, can solve problems such as excessive sludge loss and poor treatment effect, and achieve the effects of increasing organic load, improving uniformity, and increasing microbial biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

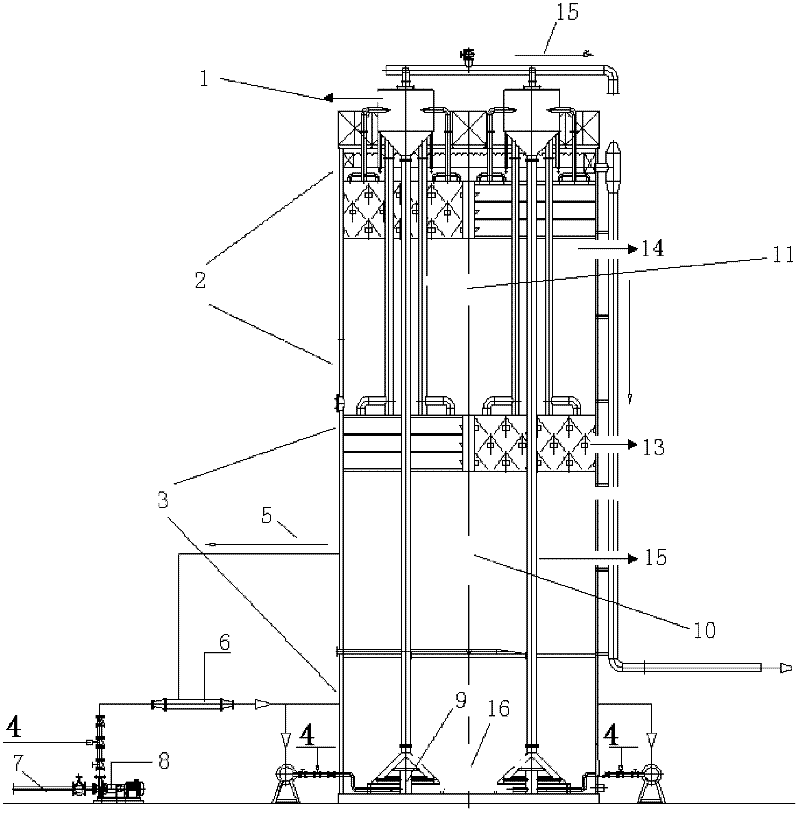

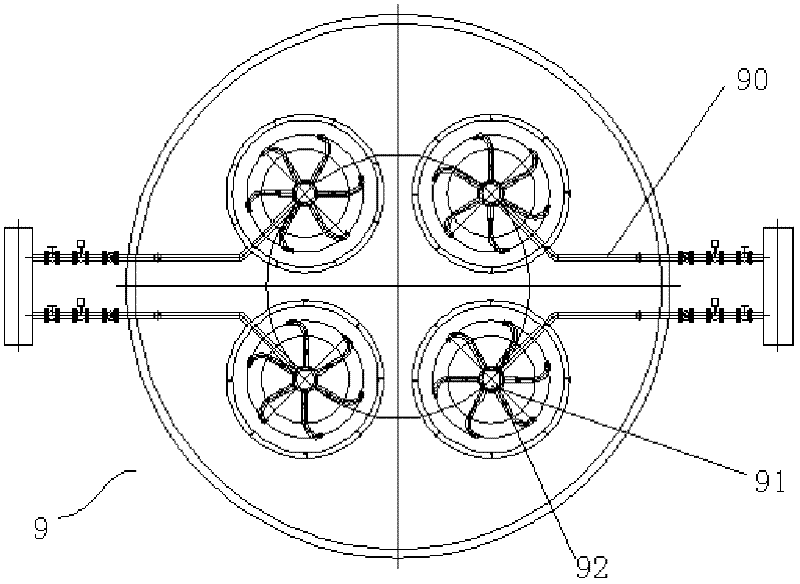

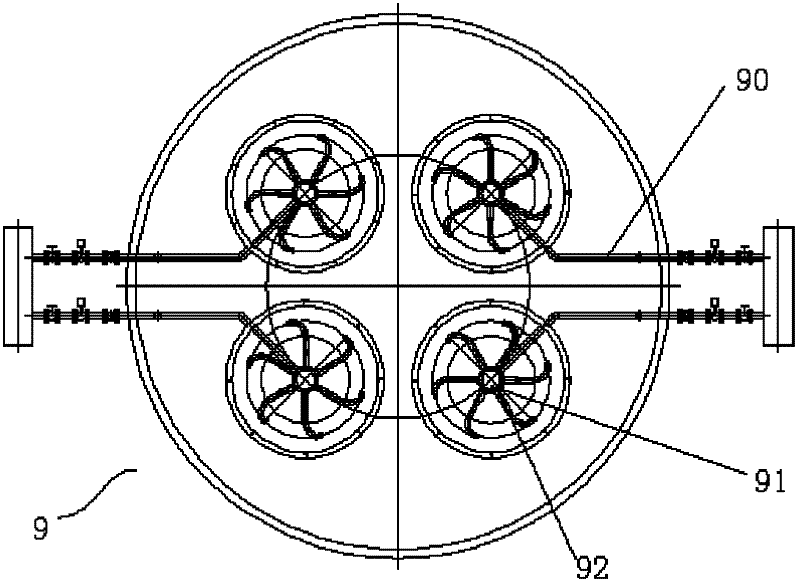

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] refer to figure 1 , figure 2 , the anaerobic processor of the present invention is formed by connecting a first UASB reactor 3 and a second UASB reactor 4 in series. Divided by function, the reactor is divided into 5 zones from bottom to top: mixing zone 16, first anaerobic zone 10, second anaerobic zone 11, precipitation zone 12 and gas-liquid separation zone 1.

[0022] Mixing zone 16: The water inflow from the bottom of the reactor, the granular sludge and the mud-water mixture returned from the gas-liquid separation zone are effectively mixed in this zone before entering the anaerobic reaction zone. The bottom is provided with an inlet pipe 7 for bean clear water, and its feed is controlled by a feed pump and an electromagnetic flowmeter 4, and an anaerobic tank feed mixer 2 can also be added on the feed pipeline for pre-mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com