Equipment and method for preparing micro-structured fiber preform of chalcogenide glass

A technology of microstructured optical fiber and chalcogenide glass, applied in glass manufacturing equipment, glass fiber products, applications, etc., can solve problems such as multiple bubbles, and achieve the effect of high production efficiency and few processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

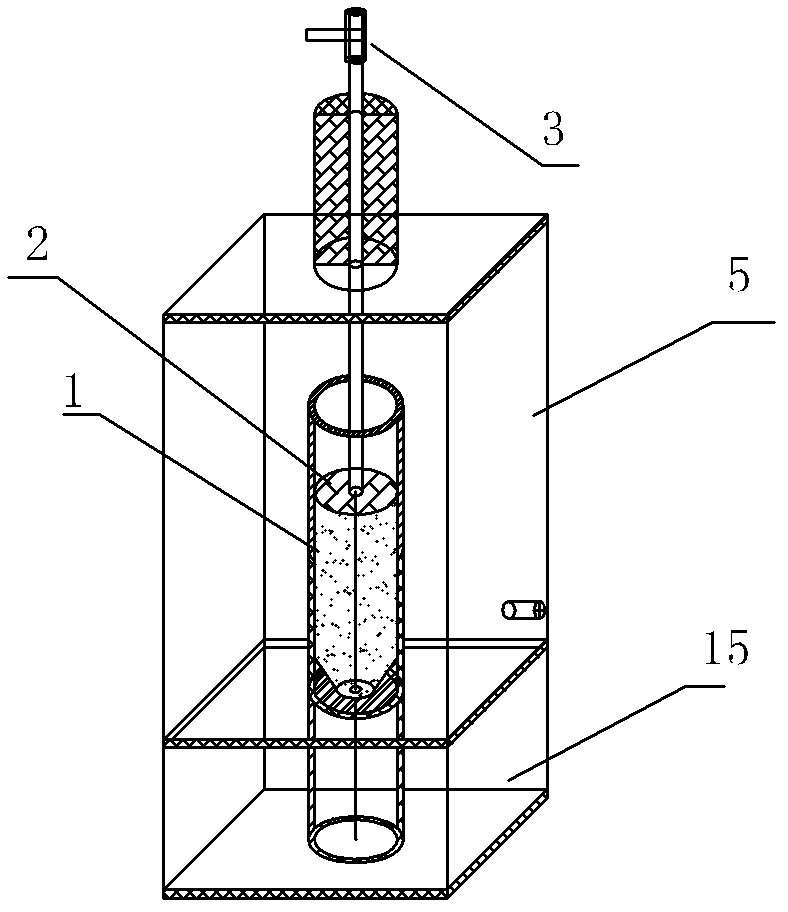

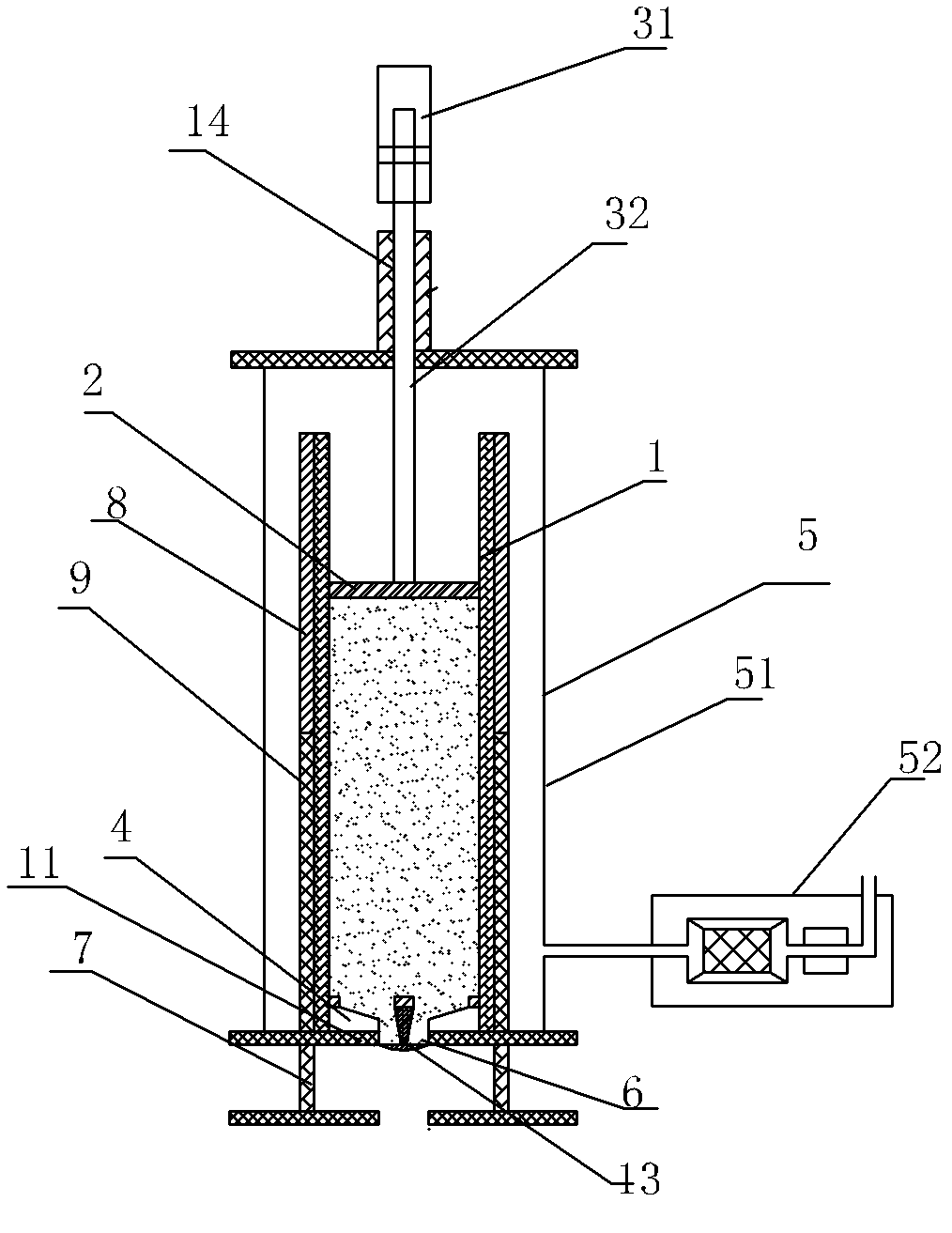

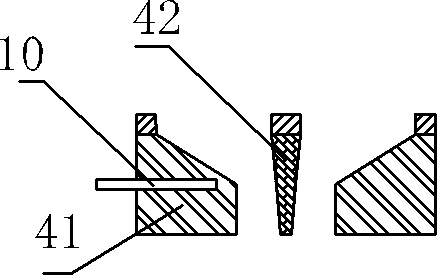

[0028] Embodiment 1: An equipment for preparing a chalcogenide glass microstructure optical fiber preform, including an extrusion cylinder 1, an extrusion pad 2, a pushing mechanism 3 and a mold 4, and a heating furnace group is arranged outside the extrusion cylinder 1, and the heating The furnace group heats the extrusion cylinder 1, a vacuum chamber 5 is arranged outside the heating furnace group, the extrusion pad 2 is arranged in the extrusion cylinder 1, the pushing mechanism 3 pushes the extrusion pad 2 to move downward, and the lower end of the extrusion cylinder 1 An extrusion port 6 is provided, the mold 4 is arranged at the extrusion port 6, and the cooling furnace 7 is arranged at the lower part of the extrusion cylinder 1 . The vacuum chamber is arranged on the base 15 .

[0029] The pushing mechanism 3 includes an electric jack 31 and an extruding rod 32 , the electric jack 31 drives the extruding rod 32 , and the extruding rod 32 is fixed to the extruding pad 2 ...

Embodiment 2

[0042] Embodiment two: a kind of method for preparing chalcogenide glass microstructure optical fiber preform comprises the following steps:

[0043] 1) Select a chalcogenide glass ingot whose △T>100℃, where △T=T x -T g , where T x is the crystallization start temperature, T g is the glass transition temperature;

[0044] 2) Select a kind of equipment for preparing chalcogenide glass microstructure optical fiber preform, including extrusion cylinder 1, extrusion pad 2, pushing mechanism 3 and mold 4, the extrusion cylinder 1 is equipped with a heating furnace group, and the heating furnace The group heats the extrusion cylinder 1, a vacuum chamber 5 is arranged outside the heating furnace group, the extrusion pad 2 is arranged in the extrusion cylinder 1, the pushing mechanism 3 pushes the extrusion pad 2 to move downward, and the lower end of the extrusion cylinder 1 is set There is an extrusion port 6, the mold 4 is arranged at the extrusion port 6, and the cooling furna...

Embodiment 3

[0049] A method for preparing a chalcogenide glass microstructure optical fiber preform, comprising the following steps:

[0050] 1) Select a chalcogenide glass ingot whose △T>100℃, where △T=T x -T g , where T x is the crystallization start temperature, T g is the glass transition temperature;

[0051] 2) Select a kind of equipment for preparing chalcogenide glass microstructure optical fiber preform, including extrusion cylinder 1, extrusion pad 2, pushing mechanism 3 and mold 4, the extrusion cylinder 1 is equipped with a heating furnace group, and the heating furnace The group heats the extrusion cylinder 1, a vacuum chamber 5 is arranged outside the heating furnace group, the extrusion pad 2 is arranged in the extrusion cylinder 1, the pushing mechanism 3 pushes the extrusion pad 2 to move downward, and the lower end of the extrusion cylinder 1 is set There is an extrusion port 6, the mold 4 is arranged at the extrusion port 6, and the cooling furnace 7 is arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com