Process for making neo-enriched p-menthane compounds

A technology for menthane and compounds, which is applied in the field of preparing new-type p-menthane-rich compounds, and can solve problems such as unattractiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

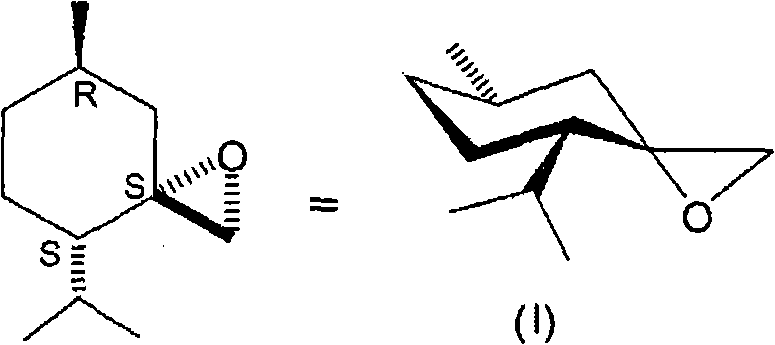

[0071] Preparation of oxaspiro(I) compound

[0072] The procedure of Duran et al. (Tetrahedron: Asymmetry 14 (2003) 2529) was generally followed. Therefore, to a band N 2 A purged and mechanically stirred 5000 ml three-necked flask was charged with sodium hydride (60% in mineral oil, 50.5 g) and anhydrous dimethylsulfoxide (800 ml). Trimethylsulfoxonium iodide (231 g, 1.05 mol) was added and the mixture was stirred at room temperature for 3 h. The flask was then placed in an ice bath, and the flask was cooled to 6°C. A mixture of 83.5% 1-menthone / 16.5% d-isomenthone (192 mL, 171 g, product of Symrise) was added over 19 min using an addition funnel. After the addition, the temperature of the flask was 8°C. The ice bath was removed and the flask was allowed to warm to room temperature. The reaction was protected from light by wrapping the flask in foil. After stirring for 20 h, the analyzed sample showed 13.8% menthone remaining and 82.4% oxaspirin product formed. The fla...

Embodiment 1-8

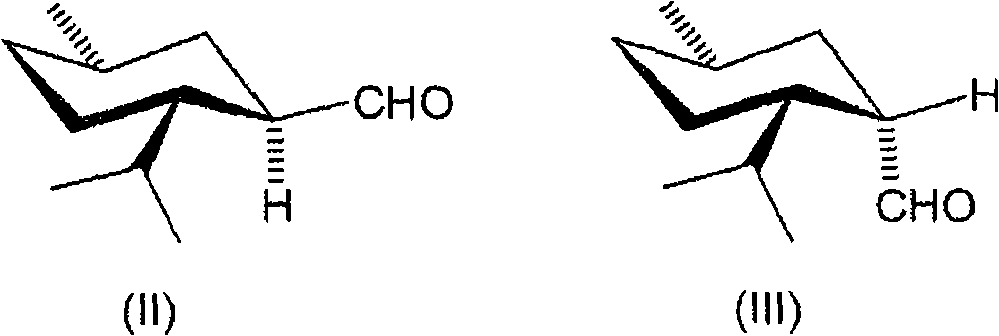

[0074] Lewis Acid-Catalyzed Rearrangement of Oxaspiro Compounds (I) to WS-1 Aldehydes

[0075] Lewis acid (5.0 mmol) was added to a solution of oxaspiro intermediate (0.2 mol) in heptane (100 mL), except in Example 2 where methyl tert-butyl ether was used as solvent. The mixture was stirred at the temperature indicated in Table 1 for a period of time until complete or substantially complete (< 2%) disappearance of the oxaspiro intermediate. GC yields of Lewis acids, WS-1 aldehydes, and novel: conventional isomer ratios are shown in Table 1.

[0076]

Embodiment 9

[0078] WS-1 and WS-1 acid chlorides enriched in novel isomers

[0079] Crude WS-1 aldehyde: the oxaspiro compound (I) (40.0g, 0.238mol) was added dropwise to ZnBr within 15min 2 (1.0 g, 0.004 mol) in a stirred reflux (102 °C) solution in heptane (230 mL), and the mixture was refluxed and analyzed periodically by GC until the concentration of the oxaspiro intermediate dropped below 1% (approximately 6 h). This reaction was repeated 4 times and the product mixture of 5 reactions gave a crude mixture (1005 g in total) containing 12.46% (124.2 g, 0.74 mol) of the WS-1 aldehyde isomer, and novel: conventional ratio ~2.3. According to the yield of (I): 62.2%.

[0080] Oxidation to Crude WS-1 Acid: Air was passed through the stirred crude aldehyde solution (obtained in the previous step) at ambient temperature using a ceramic frit bubbler for 33 hours. During the reaction, a dry ice condenser was attached over a conventional condenser using chilled water to keep the solvent (hepta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com