Electric-insulating heat-conducting polyphenyl thioether composite material and preparation method thereof

A composite material and polyphenylene sulfide technology, which are applied in the field of insulating and thermally conductive polyphenylene sulfide composite materials and their preparation, can solve the problems of low thermal conductivity and the like, and achieve simple preparation process, improved continuity, good mechanical properties and processing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

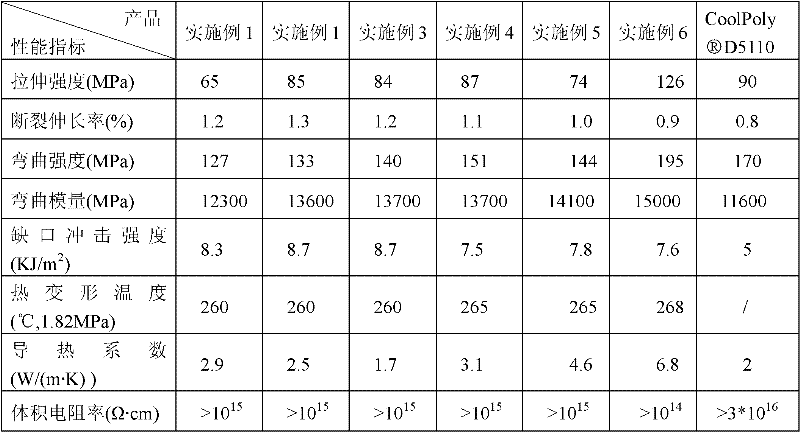

Examples

Embodiment 1

[0035] Components and parts by weight are as follows:

[0036] 20 parts polyphenylene sulfide

[0037] MgO powder 50 parts

[0038] MgO whiskers 10 parts

[0039] POE elastomer 10 parts

[0040] 10 parts non-alkali untwisted glass fiber

[0041] Silane coupling agent 1 part

[0042] Antioxidant ST-3611 0.5 parts

[0044] Put 50 parts of MgO powder, 10 parts of MgO whiskers and 1 part of silane coupling agent into the high-speed mixer, and stir at 80-120°C for 10-45 minutes; then add 20 parts of polyphenylene sulfide into the high-speed mixer, And add 10 parts of POE elastomer, 0.5 parts of antioxidant ST-3611, 1 part of silicone powder and mix evenly; the resulting mixture is added from the hopper of the extruder, and 10 parts of alkali-free and twist-free glass fiber are added from the glass fiber port , through melt extrusion and granulation to prepare insulating and heat-conducting polyphenylene sulfide composite materials.

Embodiment 2

[0046] Components and parts by weight are as follows:

[0047] 30 parts polyphenylene sulfide

[0048] MgO powder 40 parts

[0049] MgO whiskers 10 parts

[0050] POE elastomer 10 parts

[0051]10 parts non-alkali untwisted glass fiber

[0052] Titanate coupling agent 1 part

[0053] Antioxidant ST-3611 0.5 parts

[0054] Silicone powder 1 part

[0055] Put 40 parts of MgO powder, 10 parts of MgO whiskers and 1 part of titanate coupling agent into the high-speed mixer, stir at 80-120°C for 10-45 minutes; then add 30 parts of polyphenylene sulfide into the high-speed mixer , and add 10 parts of POE elastomer, 0.5 parts of antioxidant ST-3611, 1 part of silicone powder and mix evenly; Insulation and heat conduction polyphenylene sulfide composite material is obtained through melt extrusion and granulation.

Embodiment 3

[0057] Components and parts by weight are as follows:

[0058] 40 parts polyphenylene sulfide

[0059] MgO powder 30 parts

[0060] MgO whiskers 10 parts

[0061] POE elastomer 10 parts

[0062] 10 parts non-alkali untwisted glass fiber

[0063] Silane coupling agent 1 part

[0064] Antioxidant ST-36110. 0.5 parts

[0065] Silicone powder 1 part

[0066] Put 30 parts of MgO powder, 10 parts of MgO whiskers and 1 part of silane coupling agent into the high-speed mixer, and stir at 80-120°C for 10-45 minutes; then add 40 parts of polyphenylene sulfide into the high-speed mixer, And add 10 parts of POE elastomer, 0.5 parts of antioxidant ST-3611, 1 part of silicone powder and mix evenly; the resulting mixture is added from the hopper of the extruder, and 10 parts of alkali-free and twist-free glass fiber are added from the glass fiber port , through melt extrusion and granulation to prepare insulating and heat-conducting polyphenylene sulfide composite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com