Medium high temperature early strength agent for oil well cement

An oil well cement, medium and high temperature technology, applied in the field of oil well cement early strength agent, can solve the problems of obvious thickening time, low applicable temperature, long production time, etc., to reduce API water loss, improve early strength, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

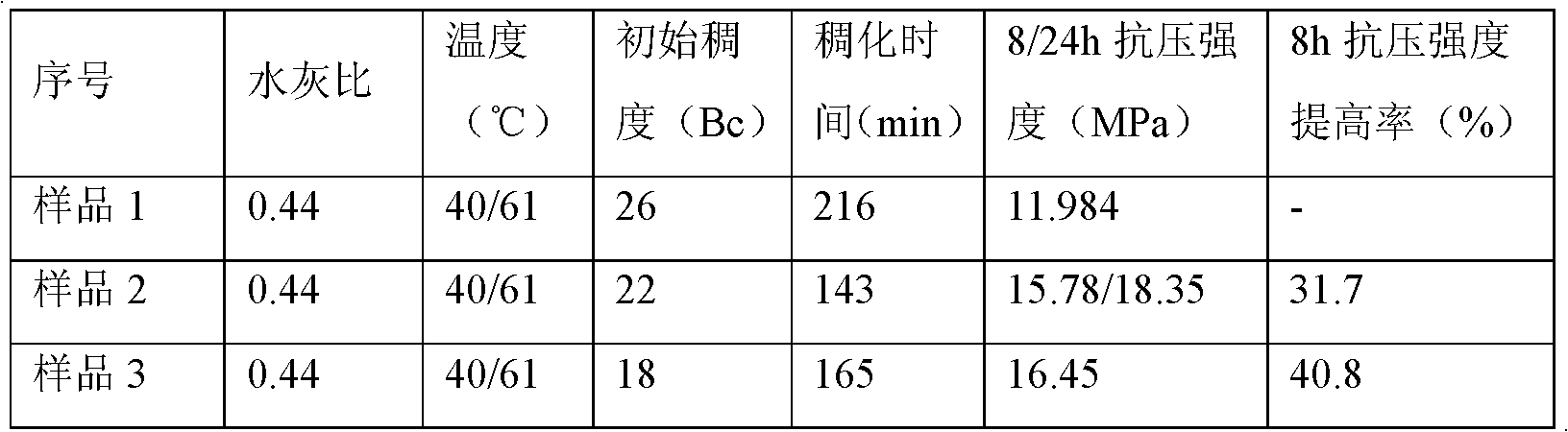

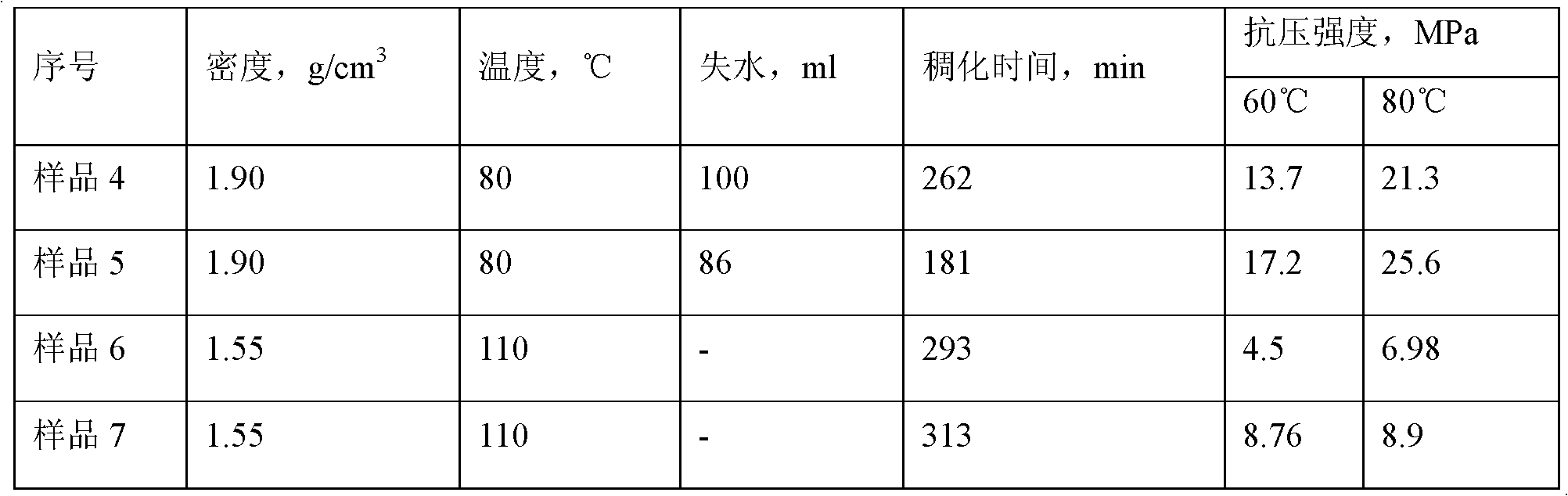

Embodiment 1

[0027] A medium-temperature early-strength agent for oil well cement, which comprises the following components, and the weight ratio of each component is:

[0028] Sodium thiosulfate 2.8,

[0029] Basic Aluminum Chloride 0.2,

[0031] microsilicon 0.4,

[0033] The high-temperature early strength agent and cement in the oil well cement made according to the above formula are sampled at a weight ratio of 4:100 to make a sample. The compressive strength of the sample under the conditions of curing temperature of 61 °C and curing time of 8 hours is 16.78MPa; this embodiment is the best embodiment of the present invention.

Embodiment 2

[0035] A medium-temperature early-strength agent for oil well cement, which comprises the following components, and the weight ratio of each component is:

[0036] Sodium thiosulfate 1.2,

[0037] Basic Aluminum Chloride 1.2,

[0038] Sodium nitrate 0.6,

[0039] micro silicon 1.

[0040] The high-temperature early strength agent and cement in the oil well cement made according to the above formula are sampled at a weight ratio of 4:100 to make a sample. The compressive strength of the sample under the conditions of curing temperature of 61 °C and curing time of 8 hours is 13.792 MPa.

Embodiment 3

[0042] A medium-temperature early-strength agent for oil well cement, which comprises the following components, and the weight ratio of each component is:

[0043] Sodium thiosulfate 1.2,

[0044] Basic Aluminum Chloride 2,

[0045] Sodium nitrate 0.4,

[0046] micro silicon 0.2,

[0048] The high-temperature early strength agent and cement in the oil well cement made according to the above formula are sampled at a weight ratio of 4:100 to make a sample. The compressive strength of the sample under the conditions of curing temperature of 61 °C and curing time of 8 hours is 2.4MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com