Method for deoxidizing coal bed gas through centrifugalization at low temperature and high speed

A high-speed centrifugation and centrifugal separator technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of high methane loss rate, low safety, consumption of coke resources, etc., to reduce methane loss rate and improve product recovery rate , the effect of reducing the explosion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

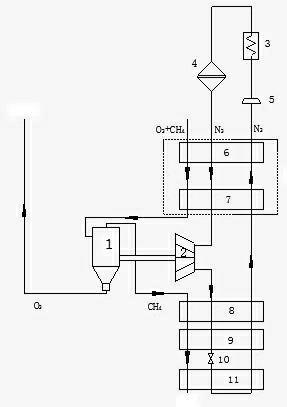

[0022] The following will be combined with figure 1 Concrete method of the present invention is described further:

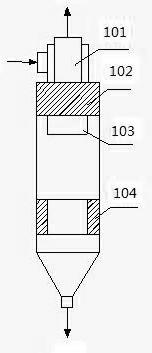

[0023] As shown in the figure, the main components applied to the coalbed methane deoxidation technology by applying the present invention are: 1 centrifugal separator, 2 expander, 3 water cooler, 4 degreaser, 5 nitrogen compressor, 6 first heat exchanger 7 second heat exchanger, 8 third heat exchanger, 9 fourth heat exchanger, 10 throttle valve, 11 fifth heat exchanger.

[0024]A method for low-temperature, high-speed centrifugal separation and deoxidation of coalbed methane. First, the first heat exchanger 6 and the second heat exchanger 7 are placed in a sealed vacuum steel plate room, and then the coalbed methane containing methane and oxygen is sequentially passed into the second heat exchanger. The first heat exchanger 6 and the second heat exchanger 7 exchange heat with the nitrogen gas in parallel flow. After cooling, the feed gas enters the centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com