Stainless steel intelligent smelting system

A stainless steel and intelligent technology, applied in the field of stainless steel intelligent smelting system, can solve the problems of cumbersome smelting process, cost increase, steel quality, inaccuracy, etc., and achieve the effect of reducing smelting time, reducing smelting cost and accurate chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

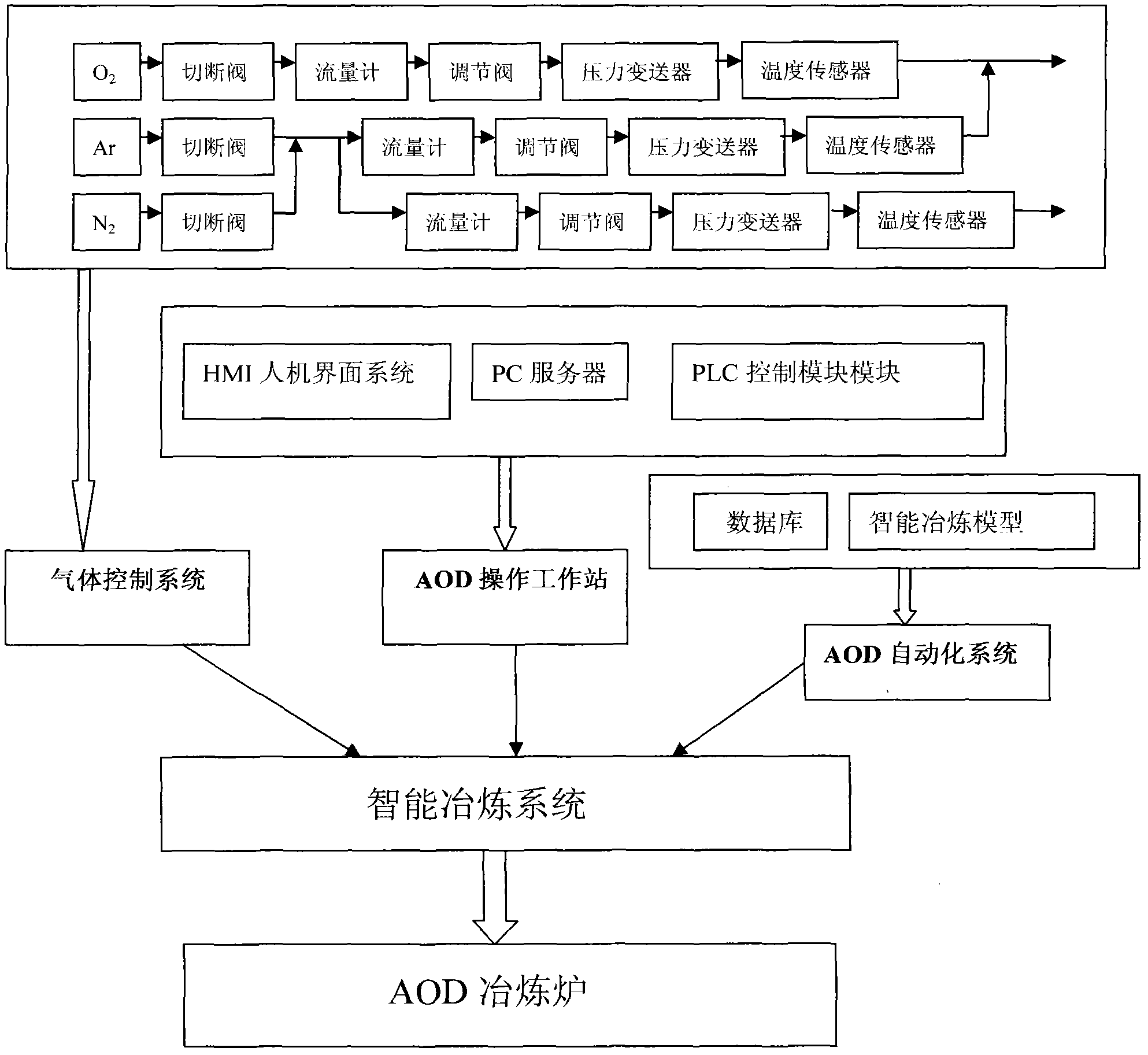

[0026] Such as figure 1 As shown, the present invention adopts a stainless steel intelligent smelting system. The stainless steel intelligent smelting system includes a stainless steel AOD smelting furnace and an intelligent smelting system connected with the stainless steel AOD smelting furnace. The intelligent smelting system consists of a gas control system and an AOD operation workstation. It is composed of an AOD automation system, the AOD operation workstation is composed of an HMI man-machine interface system, a PC server and a PLC control module, and the AOD automation system is composed of a database and an intelligent smelting model.

[0027] The gas control system is composed of an oxygen pipeline, an argon pipeline and a nitrogen pipeline, and the oxygen pipeline is connected with a shut-off valve, a flow meter, a regulating valve, a pressure transmitter and a temperature sensor; the argon pipeline is connected with a shut-off valve and the The nitrogen pipeline is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com