Pd-based transition-metal-doped binary nano-porous material and preparation method thereof

A nanoporous, transition element technology, applied in the fields of nanoscience and nanoporous material preparation, to achieve the effect of strong element holding capacity and many systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

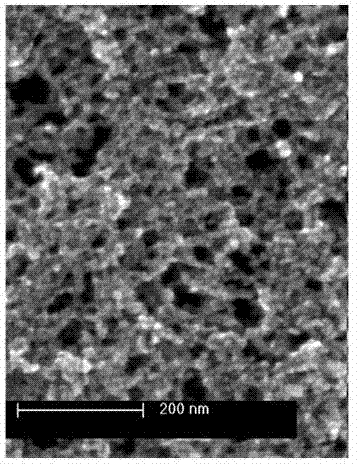

[0032] A metallic glass prealloy for Ni doping (PdNi) 80 P 20 . The Ni content is 40 at%, the Pd content is 40 at%, and the P content is controlled around 20 at%. After washing and drying (NiPd) 80 P 20 As the working electrode, Pt is used as the counter electrode, and a saturated calomel electrode is used as the reference electrode. 2 SO 4 +0.1mol / L Ni 2+ + 0.2mol / L PO 4 -3 In a mixed corrosion solution, in 0.85-0.95V Dealloyed under conditions, when the current approached to zero, the dealloyed sample was taken out, and after cleaning, a PdNi binary nanoporous material was obtained, which had an internally connected bimodal pore structure. The size of the macropore in the nanopore is about 70-80nm, the size of the small hole is about 3-5nm, and the width of the connected metal ligament tissue is about 15-20nm. The Ni content is 1-3.5 at%.

[0033]

Embodiment 2

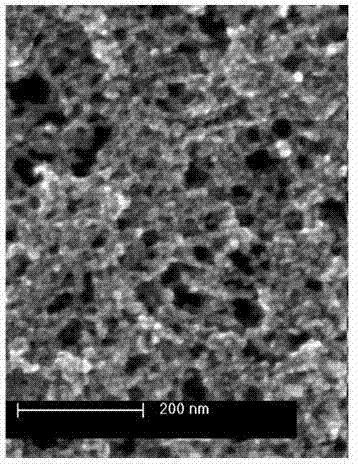

[0035] A metallic glass prealloy for Ni doping (PdNi) 80 P 20 . The Ni content can be 70 at%, the Pd content can be 10 at%, and the P content can be controlled around 20 at%. After washing and drying (NiPd) 80 P 20 As the working electrode, Pt was used as the counter electrode, and a saturated calomel electrode was used as the reference electrode, and it was placed in NaCl corrosion solution. 0.46-0.60V dealloyed under conditions, and when the current approaches zero, the dealloyed sample is taken out, and after cleaning, a PdNi binary nanoporous material is obtained, which has an internally connected bimodal pore structure. The size of the macropore in the nanopore is about 70-100nm, the size of the small hole is about 3-5nm, and the width of the connected metal ligament tissue is about 15-20nm. The Ni content is 1-4 at%.

[0036]

Embodiment 3

[0038] A Metallic Glass Prealloy for Cu Doping (PdCu) 80 P 20 . The Ni content can be 50 at%, the Pd content can be 30 at%, and the P content can be controlled around 20 at%. After washing and drying (PdCu) 80 P 20 As the working electrode, Pt was used as the counter electrode, and a saturated calomel electrode was used as the reference electrode. 2 SO 4 +0.1mol / L Cu 2+ In a mixed corrosion solution, in 0.80-0.85V dealloyed under the same conditions, and when the current approaches zero, the dealloyed sample is taken out, and after cleaning, a PdCu binary nanoporous material is obtained, which has an internally connected bimodal pore structure. The size of the macropore in the nanopore is about 70-100nm, the size of the small hole is about 3-5nm, and the width of the connected metal ligament tissue is about 15-20nm. The Cu content is 1-4 at%.

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com