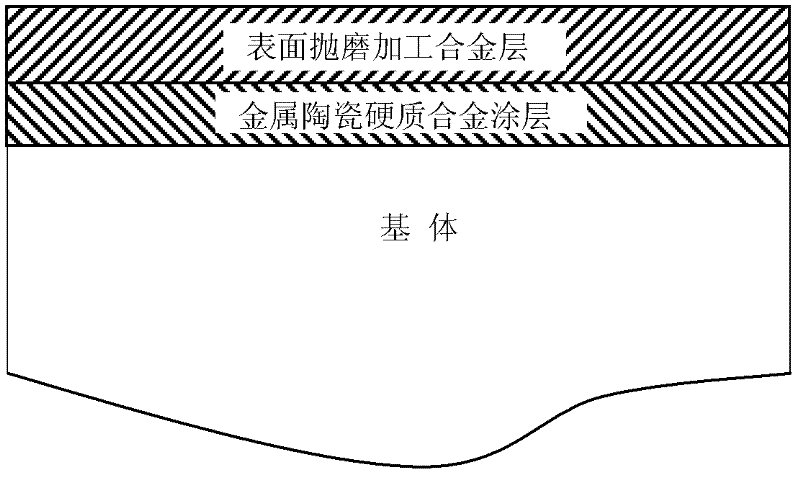

Composite gradient coating thermally sprayed on surface of screw rod of injecting and molding machine and a method for preparing same

A technology of injection molding machine screw and gradient coating, which is applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of thermal spraying coating polishing and grinding damage, etc., achieve good machinability and improve use The effect of high performance and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

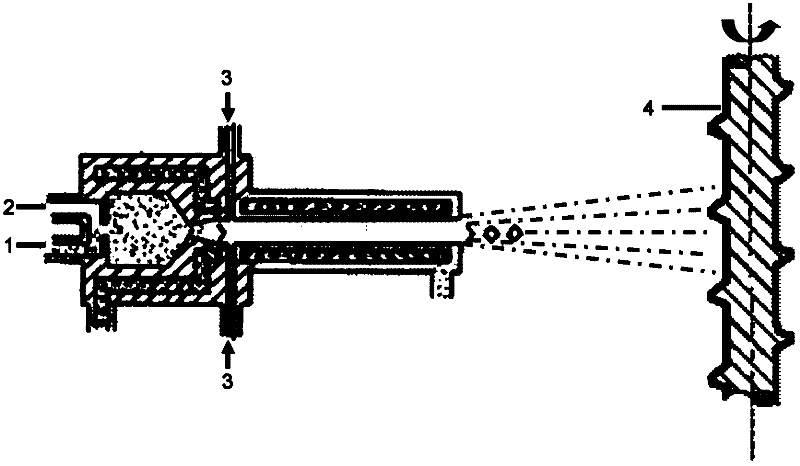

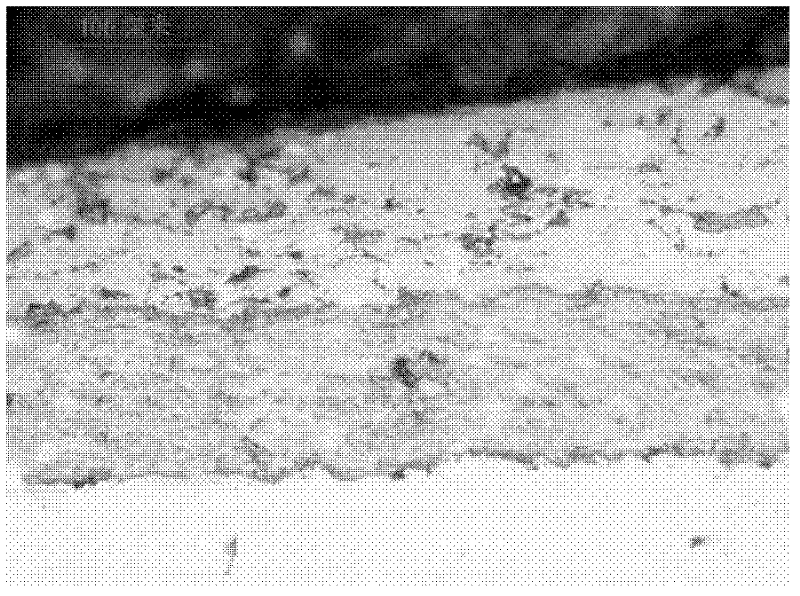

[0055] In this embodiment, the injection molding machine screw is used as the substrate to prepare a composite gradient coating on the surface of the substrate. The composite gradient coating is composed of a WC-12Co transition coating on the surface of the substrate and a Ni60 coating on the surface of the transition layer. The thickness of the WC-12Co coating is 150 μm, and the thickness of the Ni60 coating is 200 μm. The WC-12Co transition coating is prepared by thermal spraying of commercially available 15-45 μm WC-12Co powder, and the Ni60 coating is prepared by commercially available 20-40 μm Ni60 powder by thermal spraying. like figure 2 Shown, the concrete preparation method of this composite gradient coating is as follows:

[0056] 1. Before spraying, the substrate 4 is cleaned, degreased and rusted, and then 60 mesh brown corundum sand is used for surface blasting pretreatment to make its roughness meet the spraying requirements;

[0057] 2. The surface of the sub...

Embodiment 2

[0068] In this embodiment, the injection molding machine screw is used as the substrate to prepare a composite gradient coating on the surface of the substrate. The composite gradient coating is composed of a WC-10Co-4Cr transition coating on the surface of the substrate and a Ni60 coating on the surface of the transition layer. composition, the thickness of the WC-10Co-4Cr coating is 150 μm, and the thickness of the Ni60 coating is 200 μm. The WC-10Co-4Cr transition coating is prepared by thermal spraying of commercially available 15-45μm WC-10Co-4Cr powder, and the Ni60 coating is prepared by commercially available 20-40μm Ni60 powder by thermal spraying. .

[0069] The specific preparation method of the above-mentioned composite gradient coating is the same as that in Example 1, except that the powder 3 is WC-10Co-4Cr powder and Ni60 respectively, and the composite gradient coating on the surface of the substrate 4 is obtained.

[0070] The following performance test is ca...

Embodiment 3

[0075] In this embodiment, the injection molding machine screw is used as the substrate, and a composite gradient coating is prepared on the surface of the substrate. The composite gradient coating is made of Cr located on the surface of the substrate. 3 C 2 -NiCr transition coating, and the Ni60 coating on the surface of the transition layer, the Cr 3 C 2 -NiCr coating thickness is 110μm, Ni60 coating thickness is 180μm. Cr 3 C 2 -NiCr transition coating is made of commercially available 15-45μm Cr 3 C 2 -NiCr powder is prepared by thermal spraying method, and Ni60 coating is prepared by commercially available Ni60 powder of 20-40 μm by thermal spraying method.

[0076] The specific preparation method of the above-mentioned composite gradient coating is the same as the preparation method in Example 1, except that the powder 3 is respectively Cr 3 C 2 -NiCr powder and Ni60 to obtain a composite gradient coating on the surface of the substrate 4.

[0077] The following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com