Anti-ultraviolet, flame-retardant and moisture-transfer bamboo-charcoal polyester fiber and preparation method and application thereof

A polyester fiber, anti-ultraviolet technology, applied in the field of polyester fiber, can solve the problems of unseen multi-functional fiber materials, and achieve the effects of high production efficiency, strong operability and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

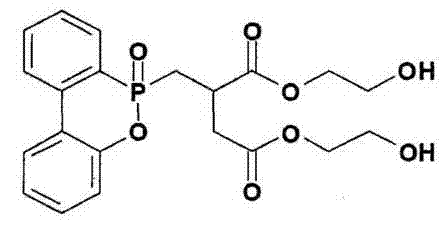

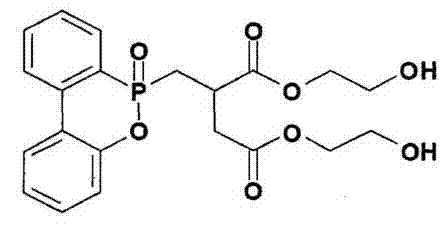

Image

Examples

Embodiment 1

[0025] 1. An anti-ultraviolet, bamboo charcoal, flame-retardant and moisture-conducting polyester fiber, which is composed of the following raw materials: 10 kg of anti-ultraviolet masterbatch, 20 kg of activated carbon masterbatch, copolymerized phosphorus-based flame-retardant polyester fiber-forming resin 85 kg, and the special-shaped cross-section is a cruciform cross-section.

[0026] 2. Preparation of anti-ultraviolet, bamboo charcoal, flame-retardant and moisture-conducting polyester fibers:

[0027] (1) Take the anti-ultraviolet agent of 10-20% by weight and the polyethylene terephthalate blend of 80-90% by weight, extrude with screw extruder, pelletize, and obtain anti-ultraviolet Masterbatch, spare, wherein the blending temperature is 200~250℃, the screw speed is 150~200rpm;

[0028] (2) Grind the bamboo charcoal into fine powder, then blow the bamboo charcoal fine powder with compressed air, enrich and obtain activated carbon particles of 300nm to 500nm, and then ...

Embodiment 2

[0044] 1. An anti-ultraviolet, bamboo charcoal, flame-retardant and moisture-conducting polyester fiber, which is composed of the following raw materials: 5 kg of anti-ultraviolet masterbatch, 10 kg of activated carbon masterbatch, copolymerized phosphorus-based flame-retardant polyester fiber-forming resin 70 kg, the special-shaped cross-section is a multi-leaf cross-section.

[0045] 2. Preparation of anti-ultraviolet, bamboo charcoal, flame-retardant and moisture-conducting polyester fibers:

[0046] (1) Take the anti-ultraviolet agent of 10-20% by weight and the polyethylene terephthalate blend of 80-90% by weight, extrude with screw extruder, pelletize, and obtain anti-ultraviolet Masterbatch, spare, wherein the blending temperature is 200~250℃, the screw speed is 150~200rpm;

[0047] (2) Grind the bamboo charcoal into fine powder, then blow the bamboo charcoal fine powder with compressed air, enrich and obtain activated carbon particles of 300nm to 500nm, and then mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com