Construction method of stirring pile and solidifying agent device thereof

A construction method and technology of curing agent, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of low water content of hard shell layer, increase construction time and cost, reduce construction efficiency of mixing pile, etc. The effect of pile body quality, improving construction efficiency and saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

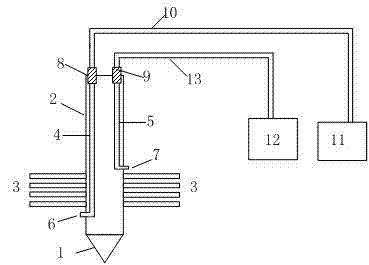

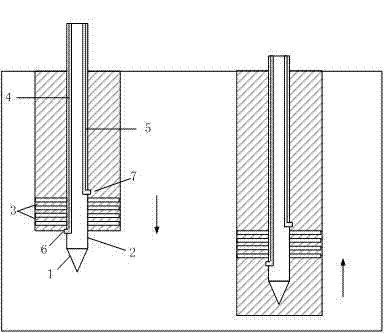

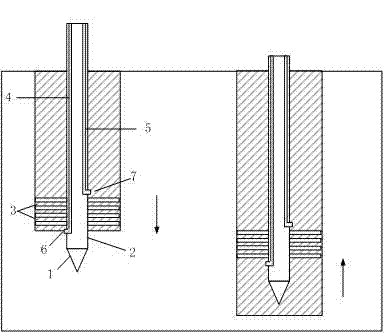

[0025] A construction method of a stirring pile, the stirring pile machine is positioned on the pile position, the nozzle of the first curing agent injection pipe is guided to the blade of the stirring drill bit of the stirring pile machine, and then the nozzle of the second curing agent injection pipe is guided to Go to the top of the blade of the mixing drill bit of the mixing pile machine, start the mixing pile machine, make the mixing drill bit sink, the stirring blade rotates, and at the same time spray the soil curing agent to the soil through the first curing agent injection pipe, when the mixing drill bit sinks to the pile end When the design elevation is set, stop the mixing blades from sinking, and stop spraying the soil curing agent to the soil through the first curing agent injection pipe, then lift the mixing drill bit, the stirring blades rotate, and at the same time spray the soil solidification agent to the soil through the second curing agent injection pipe Whe...

Embodiment 2

[0034]A construction method of a stirring pile, the stirring pile machine is positioned on the pile position, the nozzle of the first curing agent injection pipe is guided to the blade of the stirring drill bit of the stirring pile machine, and then the nozzle of the second curing agent injection pipe is guided to Go to the top of the blade of the mixing drill bit of the mixing pile machine, start the mixing pile machine, make the mixing drill bit sink, the stirring blade rotates, and at the same time spray the soil curing agent to the soil through the first curing agent injection pipe, when the mixing drill bit sinks to the pile end When the design elevation is set, stop the mixing blades from sinking, and stop spraying the soil curing agent to the soil through the first curing agent injection pipe, then lift the mixing drill bit, the stirring blades rotate, and at the same time spray the soil solidification agent to the soil through the second curing agent injection pipe When...

Embodiment 3

[0043] A method for construction of mixing piles on soft ground with high water content and hard crust, positioning the mixing pile machine on the pile position, leading the nozzle of the first curing agent injection pipe to the mixing drill bit of the mixing pile machine Below the blades, lead the nozzle of the second curing agent injection pipe to the top of the blade of the stirring drill bit of the stirring pile machine, start the stirring pile machine, make the stirring drill sink, the stirring blades rotate, and at the same time pass the first curing agent injection pipe to the Spray soil curing agent dry powder into the soil. When the mixing drill bit sinks to the design elevation of the pile end, stop the stirring blade sinking, and stop spraying soil curing agent dry powder through the first curing agent injection pipe to the soil, then lift the mixing drill bit, and stir The blades rotate, and when the agitating bit is lifted to the bottom surface of the crust, water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com