Flour wet gluten automatic detection device and detection method

An automatic detection and wet gluten technology, which is applied in the direction of chemical reaction of materials and material analysis by observing the influence of chemical indicators. Wet gluten washing of flour, etc., to achieve the effect of firm and lightweight aluminum alloy shell, flexible and convenient control method, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

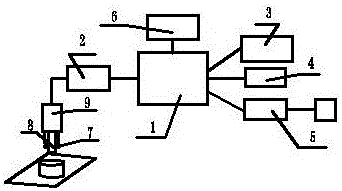

[0035] The flour wet gluten automatic detection device used in the monitoring method of the present invention comprises: an industrial control computer 1, the industrial control computer is connected to an illuminance measurement and control circuit 2, a liquid crystal screen 3, a touch screen 4, and a printer 5, and the illuminance measurement and control The circuit is connected to the imaging device 6 .

Embodiment 2

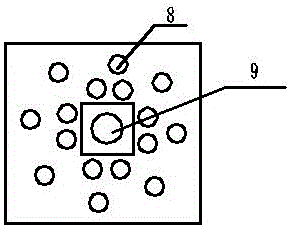

[0037] The flour wet gluten automatic detection device described in embodiment 1, described camera device comprises camera 7, and described camera is connected with the illuminating light source 8 and lens 9 of bright white light-emitting diode without flickering; Described camera is MV300UC A color industrial-grade camera with a maximum resolution of 2048×1536, a maximum shooting speed of 38 frames per second, a signal-to-noise ratio greater than 43dB, power supply directly through the USB interface, power consumption of less than 1W, and support for image sizes, Exposure time, white balance, black level and other characteristics are programmable, and the control method is very flexible and convenient. The lighting source described is a double-ring array structure with 8 inner and 8 outer lights.

Embodiment 3

[0039] Flour wet gluten automatic detection device described in embodiment 1, described industrial control computer is a 3.5-inch single-board industrial control computer, and described 3.5-inch single-board industrial control computer adopts chipset AMDLX800CPU, AMDLX800+CS5536 with 1GB internal memory , providing a slot DDR SO-DIMM that can support a maximum of 1GB; the audio of the 3.5-inch single-board industrial control computer supports decoding Realtek ALC203 with AC97, and the network of the 3.5-inch single-board industrial control computer provides a 10 / 100Mbps Single RTL8100C network chipset, the network chipset has PC / 104, ISA bus, expansion slot and watchdog; the motherboard port of the 3.5-inch single-board industrial control computer includes Digital IO ports 7 RS-232 , I / O interface 1 RS-232 / 422 / 485, display interface 4 USB2.0 and I / O interface 1 IDE, the display interface includes a 18-bit single-channel LVDS and a 24-bit TTL port, the main board is an 8-layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power consumption | aaaaa | aaaaa |

| Snr | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com