Method for detecting content of beta-lactoglobulin in dairy product

A detection method and a lactoglobulin technology are applied in the detection field of beta-lactoglobulin content, which can solve the problems of inaccurate determination of beta-lactoglobulin, long analysis time, poor accuracy, etc. Good and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

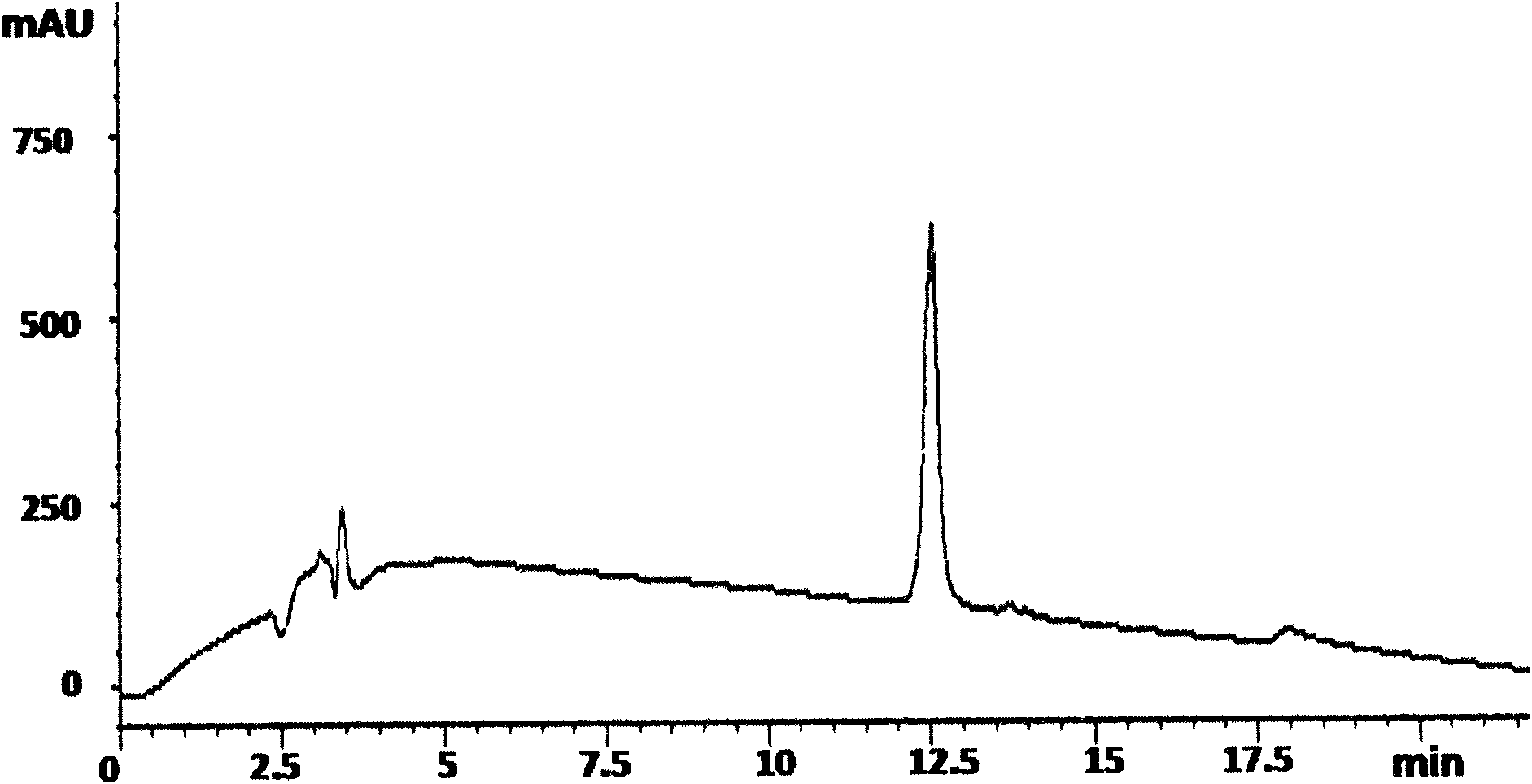

[0040] Example 1 Determination of β-lactoglobulin in infant milk powder

[0041] ①Centrifugal degreasing: Accurately weigh 10g of infant milk powder (commercially available) sample, dissolve it completely in 100mL of water, and then centrifuge at 4000r / min for 10min at 4°C to remove the floating fat on the upper layer to obtain a degreased sample;

[0042] ②Purification: Take 5mL of 0.10mol / L acetate buffer solution with a pH value of 4.6 and 1mL of degreased sample in a 10mL centrifuge tube, mix well with a vortex shaker for 2min, and centrifuge at 8000r / min for 10min at 4°C , take the supernatant;

[0043] ③Filtration: The supernatant is filtered through a 0.45μm filter membrane to obtain the supernatant;

[0044] ④ Take 10 μL of the upper machine solution into the high-performance liquid chromatograph.

[0045] The content of β-lactoglobulin in infant milk powder was measured to be 15.8mg / g.

Embodiment 2

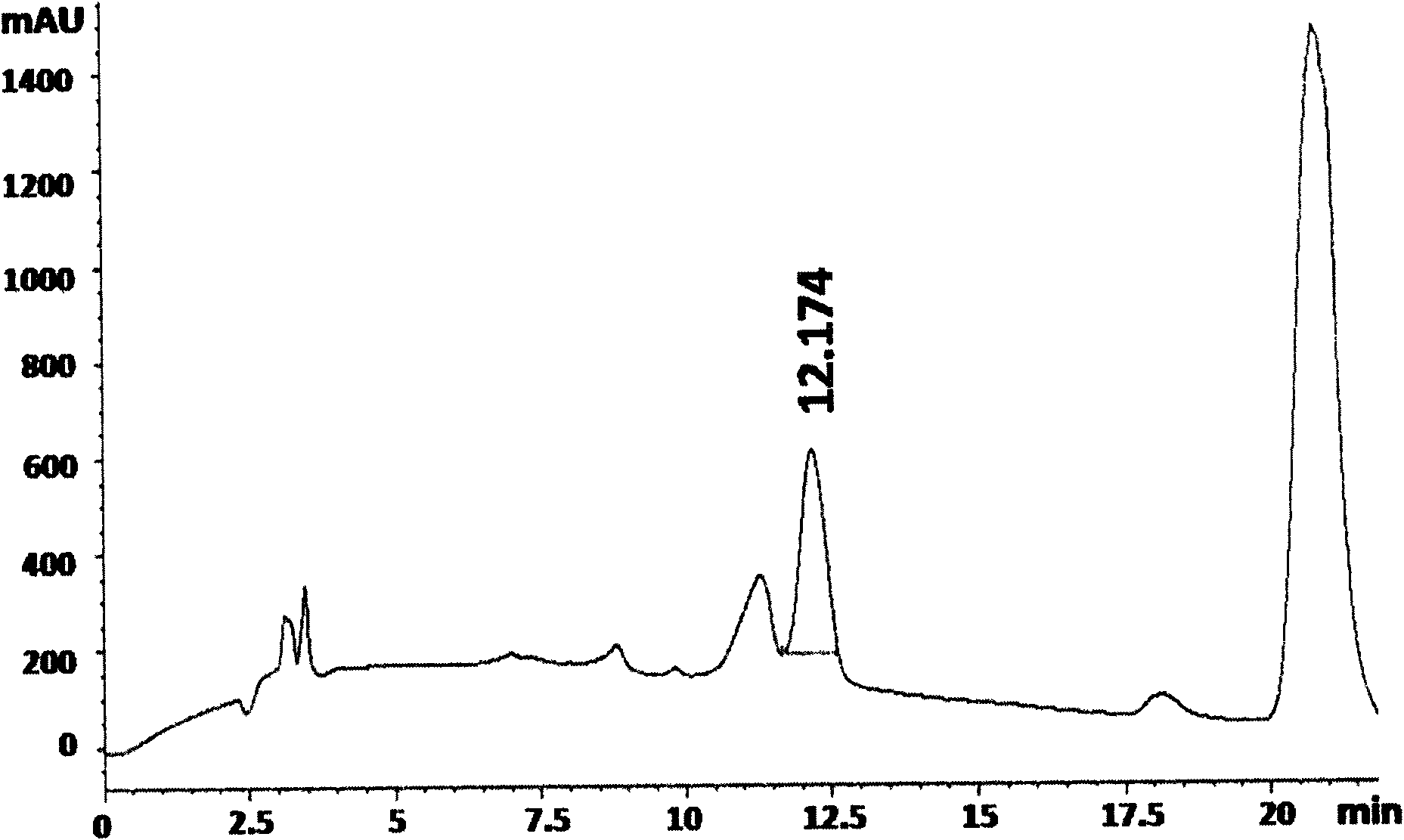

[0046] Example 2 Determination of the content of β-lactoglobulin in milk beverage

[0047] ①Centrifugal degreasing: take 500ml of milk drink sample (commercially available), centrifuge at 4°C at a speed of 4000r / min for 10min, remove the floating fat on the upper layer to obtain a degreasing sample;

[0048]②Purification: Take 5mL of 0.10mol / L acetate buffer solution with a pH value of 4.6 and 1mL of degreased sample in a 10mL centrifuge tube, mix well with a vortex shaker for 2min, and centrifuge at 8000r / min for 10min at 4°C. Take the supernatant;

[0049] ③Filtration: The supernatant is filtered through a 0.45μm filter membrane to obtain the supernatant;

[0050] ④ Take 10 μL of the upper machine solution into the high-performance liquid chromatograph.

[0051] The content of β-lactoglobulin in the milk drink was measured to be 2.2 mg / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com