Wide band sound absorption structure of film mechanical impedance combined with micropunched plate acoustic impedance

A technology of micro-perforated plate and mechanical impedance, which is applied in the direction of sound-generating devices and instruments, and can solve problems such as complex structure, large space occupation, and thickening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

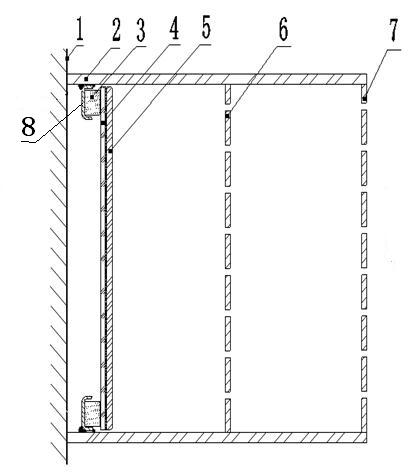

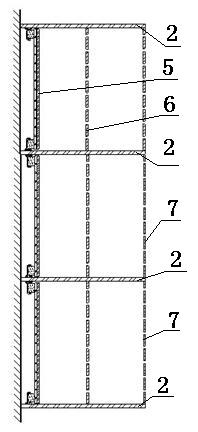

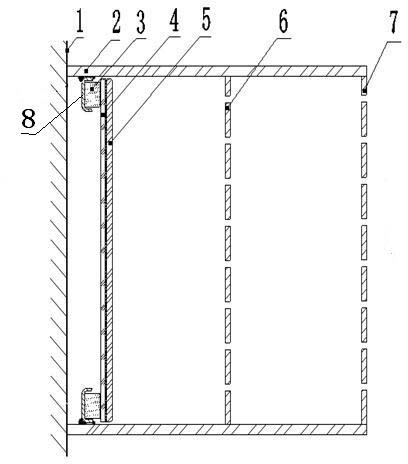

[0013] The following is attached figure 1 The present invention is described in further detail:

[0014] The present invention includes a bracket 2 fixedly installed on the wall 1. There are two brackets 2, and the two brackets 2 are installed up and down along the wall 1, and are all perpendicular to the wall 1. The bracket 2 is made of a metal plate with a thickness of 1 mm. . Connect the front micro-perforated plate 7 and the rear micro-perforated plate 6 between the two supports 2, the front micro-perforated plate 7 is installed on the front of the support 2, and the rear micro-perforated plate 6 is installed on the rear of the support 2, so that the front micro-perforated The plate 7 and the rear micro-perforated plate 6 are vertical to the support 2 respectively, a rectangular cavity is formed between the micro-perforated plate 7 and the rear micro-perforated plate 6, and another rectangular cavity is formed between the rear micro-perforated plate 6 and the wall 1. Loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com