Common-rail fuel supply system of fuel cell or multi-fuel engine

A multi-fuel engine, common rail fuel technology, applied in fuel cells, fuel cell additives, charging systems, etc., can solve the problem that the fuel cell system or fuel cell engine fuel supply cannot be accurately controlled, the fuel cell engine system is complex, The system has problems such as poor dynamic response performance, which can improve the control accuracy and dynamic response speed, solve the pressure balance problem, and have a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

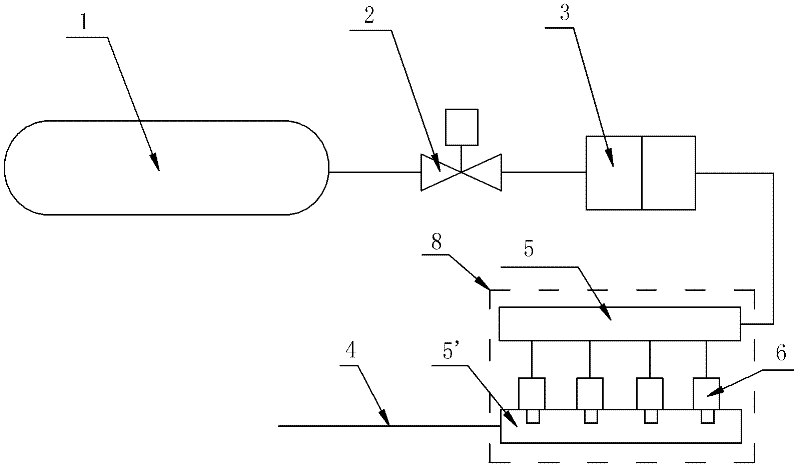

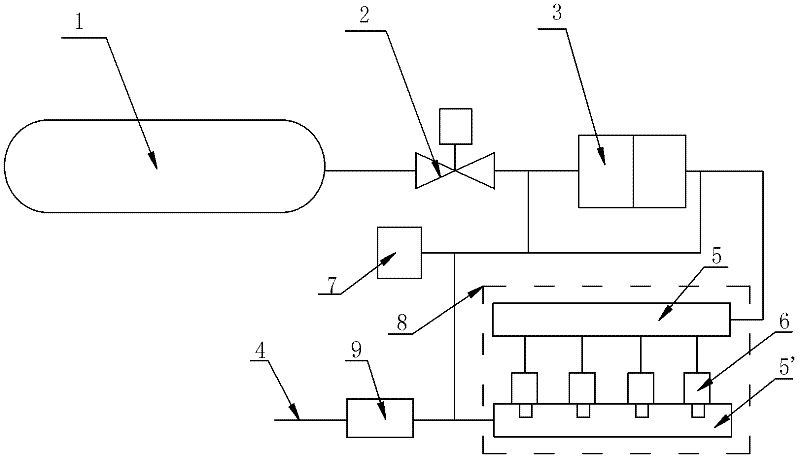

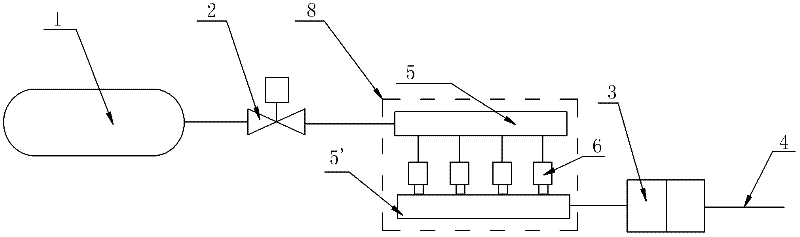

[0023] The first implementation of the present invention is as figure 1 As shown, the fuel source 1 is made of high-pressure hydrogen cylinders, which include necessary components such as buffer valves and overflow valves. Of course, in the present invention, it is not limited to the use of hydrogen fuel, and it can also be CNG (compressed natural gas), LPG (liquefied petroleum gas), etc. gas), gasoline, ethanol gasoline and other available fuels. The high-pressure hydrogen bottle 1 is connected with a fuel delivery pipeline 4, which can provide fuel for a fuel cell, a fuel cell engine, or a multi-fuel engine. A valve 2, a pressure regulator 3 and a common rail injection device 8 are sequentially connected in series in the fuel delivery pipeline 4, wherein the common rail injection device 8 includes two fuel rails 5, 5' at the front and rear, and two fuel rails connected in parallel. Between a plurality of injectors 6, the input end of each injector 6 is connected with the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com