Die processing method, die, objective lens, and optical pick-up device

A technology of optical pick-up device and processing method, applied in metal processing equipment, recording/reproducing by optical method, optics, etc., can solve the problems of cost increase, unfavorable miniaturization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

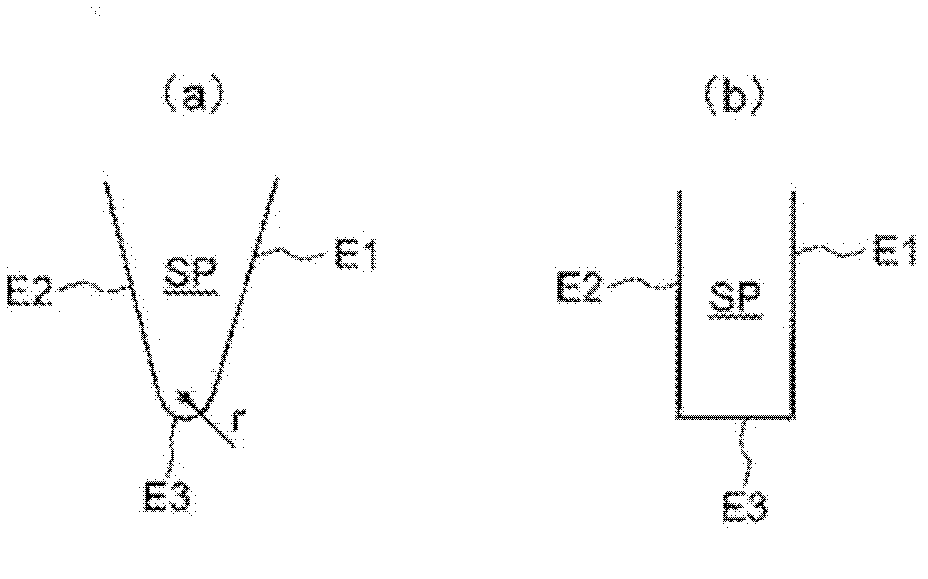

[0150] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Figure 7 (a) is a perspective view showing a cutting edge of a diamond tool, that is, a cutting blade, Figure 7 (b) is an enlarged view showing the shape of the tip end of the rake face of the cutting insert. The sword point cutting blade SB of the diamond tool is welded to the holder S as shown in the figure, and has a rake surface SP facing the rotation direction of the die to be cut. The top end of the rake surface SP consists of a linear first edge E1, a linear second edge E2 extending in a direction intersecting at an acute angle with respect to the first edge E1, and a connecting edge E1, E2. The arc-shaped third edge portion E3 between the end portions on the tip side constitutes an outline. In addition, the radius r of the third edge portion E3 is set to be 5 μm or less, preferably 2.5 μm or less, but may be 0.5 μm or more in order to ensure a lifetime.

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com