Method of improving fragrance component content of stem extracting solution

A technology for aroma components and extracting solution, which is applied in the field of improving the content of aroma components in tobacco stem extraction solution, can solve the problems of affecting the sensory quality of tobacco slices, poor aroma and high irritation of tobacco slices, and achieves improvement of cigarette smoking taste, value enhancement, The effect of increasing the acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation of tobacco stem extract

[0021] Take a certain amount of tobacco stems (crushed by Guangdong China Tobacco Industry Co., Ltd. Raw Material Research Institute), add 8 times the weight of water, shake and extract 3 times in a constant temperature water bath shaker at 50°C at a speed of 250r / min, each time for 1h, and combine extracting liquid, and collecting the filtrate by filtration to obtain tobacco stem extracting liquid.

Embodiment 2

[0022] Embodiment 2: tobacco stem extract fermentation

[0023] Take a plurality of 250mL Erlenmeyer flasks, add 200mL of the tobacco stem extract prepared in Example 1 respectively, put them into a high-pressure steam sterilizer, and sterilize at 115° C. for 20 minutes, and set aside. Take the aromatic yeast strain (Angola aromatic yeast) and transfer it to the slant of YPD medium, activate and culture it at 30°C for 12 hours, then take the activated and cultivated aroma yeast strain slant, absorb 5mL of sterile water to wash the colonies, and make bacteria Suspension, the number of bacteria in the suspension is 2.5×10 5 ~3×10 5 . The bacterial suspension was inoculated into a bottle of sterilized tobacco stem extract medium according to the inoculation amount of 1% volume, and fermented and cultivated in an incubator at 30° C. for 60 h. At the same time, another two bottles of sterilized tobacco stem extract were added with the same amount of sterile water as a control, a...

Embodiment 3

[0024] Example 3: Changes in the number of aromatic yeasts and changes in the pH of the fermentation broth during fermentation

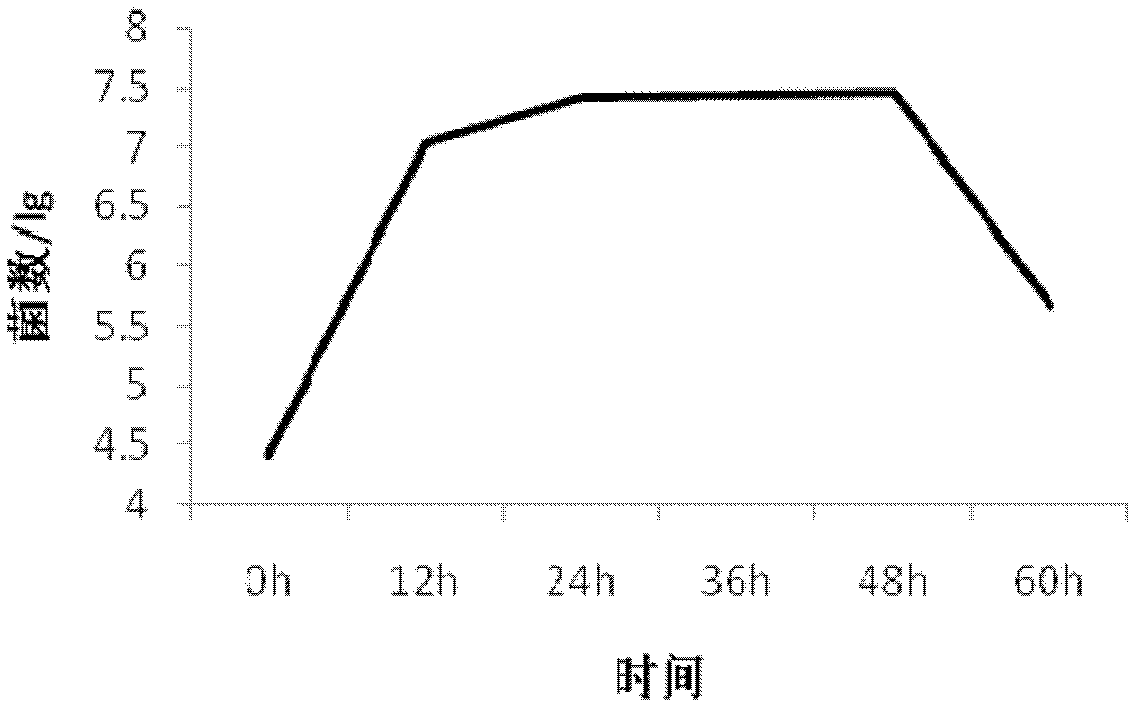

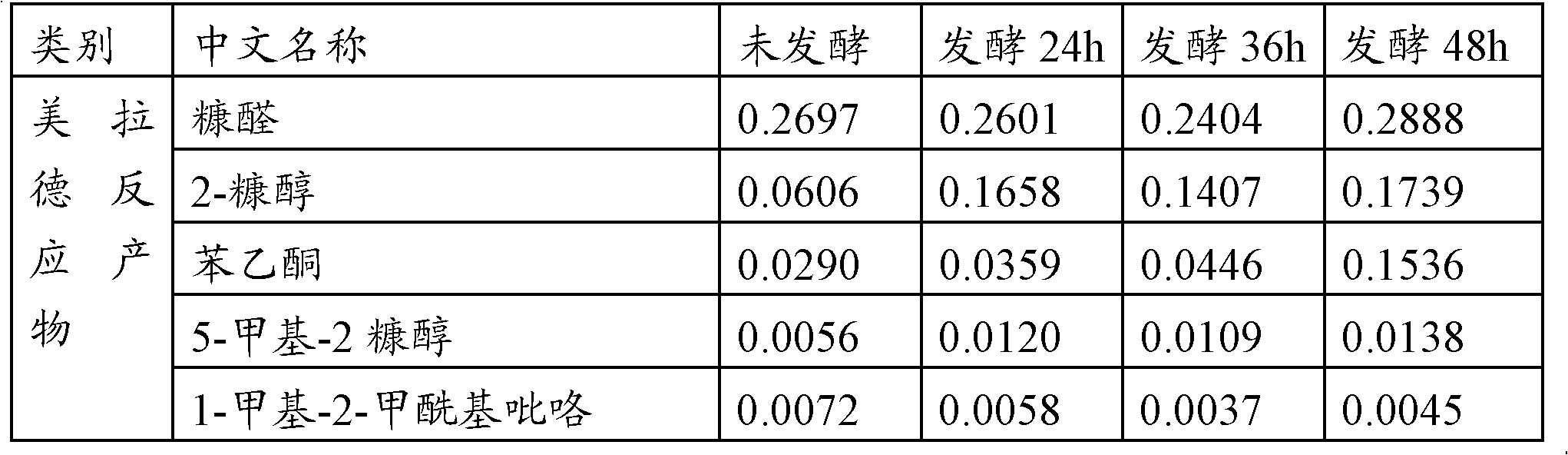

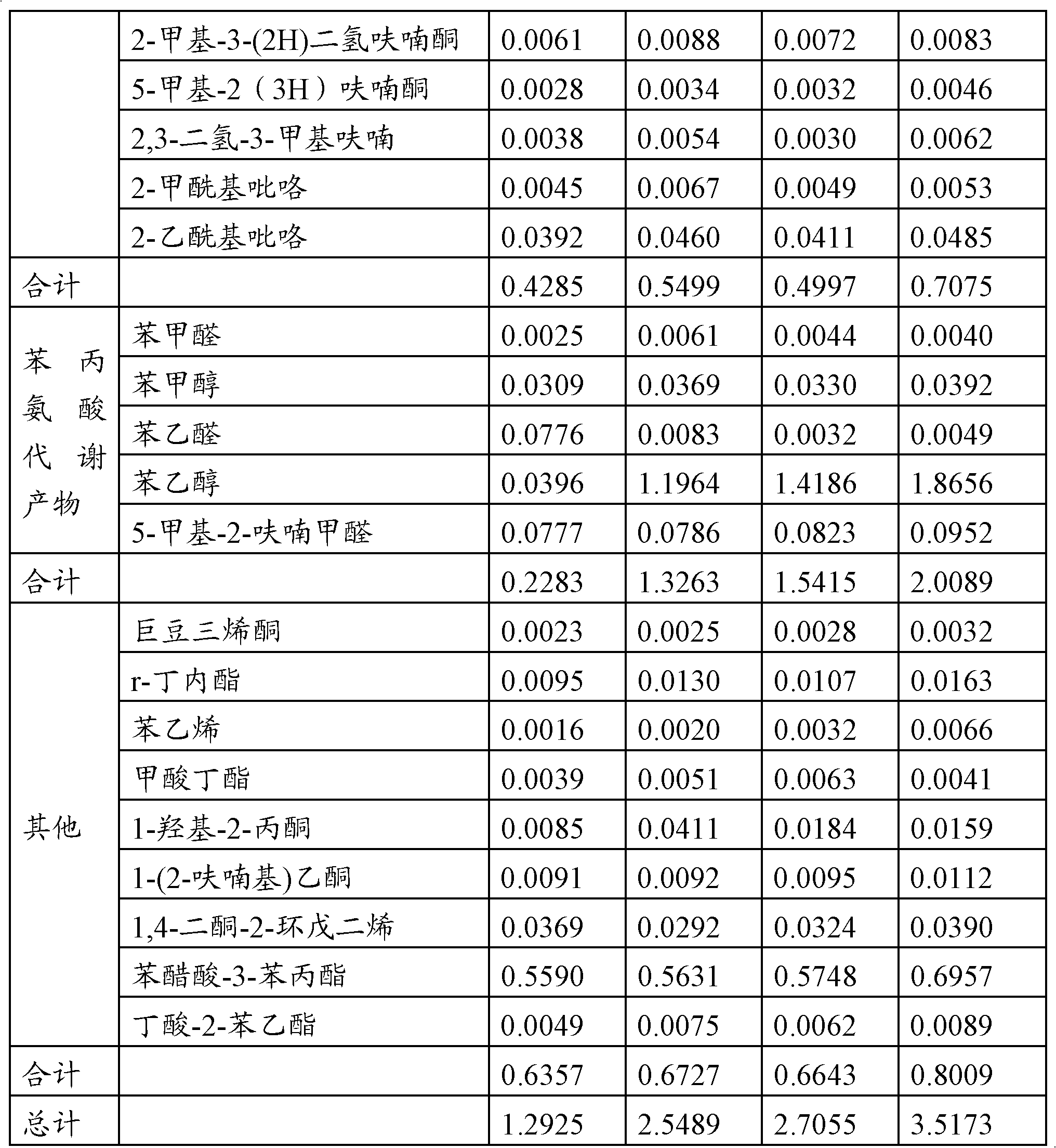

[0025] According to the method described in Example 2, the tobacco stem extract was taken, and after sterilization, it was inserted into the aroma yeast for 60 hours at an inoculum size of 1%, and the samples were taken at 0h, 12h, 24h, 36h, 48h and 60h after the inoculation to ferment After the yeast is counted, and the pH of the fermented liquid is measured, the results are shown in Table 1 and figure 1 shown.

[0026] Table 1 Changes in the number of yeast and the pH of the fermentation broth during the fermentation process

[0027] fermentation time

yeast count

pH

0h

27000

5.37

12h

10900000

4.42

24h

26300000

4.38

36h

27000000

4.40

48h

28500000

4.39

60h

480000

4.38

[0028] From Table 1 and figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com