Precise forming method of high-temperature alloy mounting seat

A technology of precision forming and high-temperature alloys, applied in engine components, mechanical equipment, etc., can solve the problems of reduced performance of parts, large processing workload, long manufacturing cycle, etc., to achieve short manufacturing cycle, less processing workload, and short process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

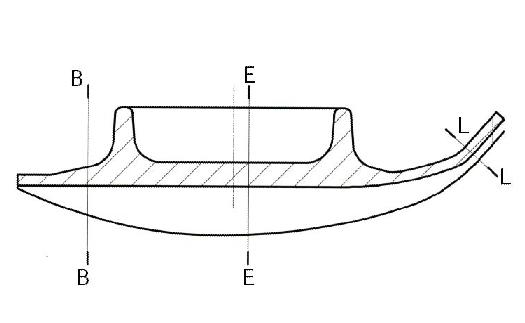

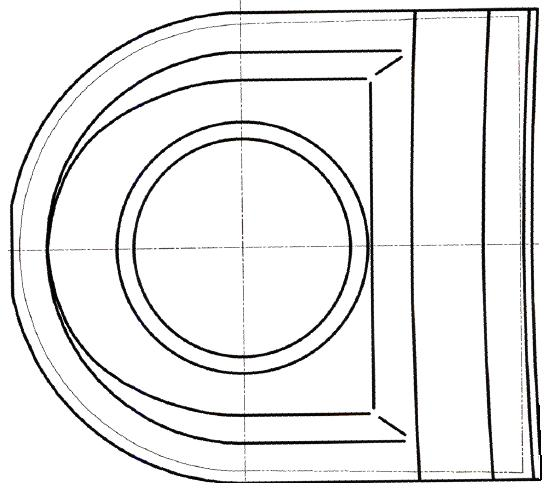

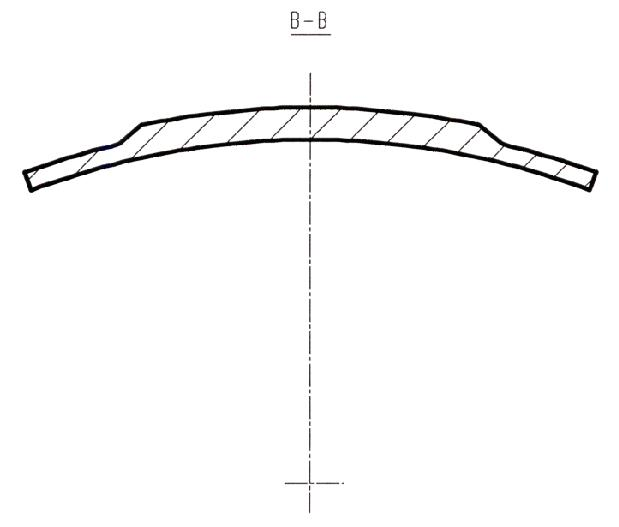

Image

Examples

Embodiment 1

[0028] This embodiment provides a precision forming method for a superalloy mounting seat, which is characterized in that: the main process route of the precision forming method for a high temperature alloy mounting seat is billet making, pre-forging, pre-forming, forming, solution heat treatment, and cold correction ;

[0029] Billet making process: blanking, drawing, surface cleaning, double cutting, surface cleaning, tire die forging, marking, surface cleaning, inspection;

[0030] The die forging process is as follows: surface cleaning to remove oxide layer and surface defects, thickness grouping, glass lubricant coating, first pre-forging, burr removal, surface cleaning to remove oxide layer and surface defects, glass lubricant coating, and second forging Secondary pre-forging, removal of burrs, surface cleaning to remove oxide layer and surface defects, coating of glass lubricant, third pre-forging, surface cleaning to remove oxide layer and surface defects, coating of g...

Embodiment 2

[0042] This embodiment provides a precision forming method for a superalloy mounting seat, which is characterized in that: the main process route of the precision forming method for a high temperature alloy mounting seat is billet making, pre-forging, pre-forming, forming, solution heat treatment, and cold correction ;

[0043] Billet making process: blanking, drawing, surface cleaning, double cutting, surface cleaning, tire die forging, marking, surface cleaning, inspection;

[0044] The die forging process is as follows: surface cleaning to remove oxide layer and surface defects, thickness grouping, glass lubricant coating, first pre-forging, burr removal, surface cleaning to remove oxide layer and surface defects, glass lubricant coating, and second forging Secondary pre-forging, removal of burrs, surface cleaning to remove oxide layer and surface defects, coating of glass lubricant, third pre-forging, surface cleaning to remove oxide layer and surface defects, coating of g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com