Heavy gear transmission vertical broaching machine tool

A gear transmission, vertical technology, applied in the direction of belt/chain/gear, gear teeth, mechanical equipment, etc., can solve the problems of unsuitable heavy and large workpiece, accurately determine the source of system failure, and limit the processing range, and achieve a compact structure. , The effect of shortening maintenance time and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

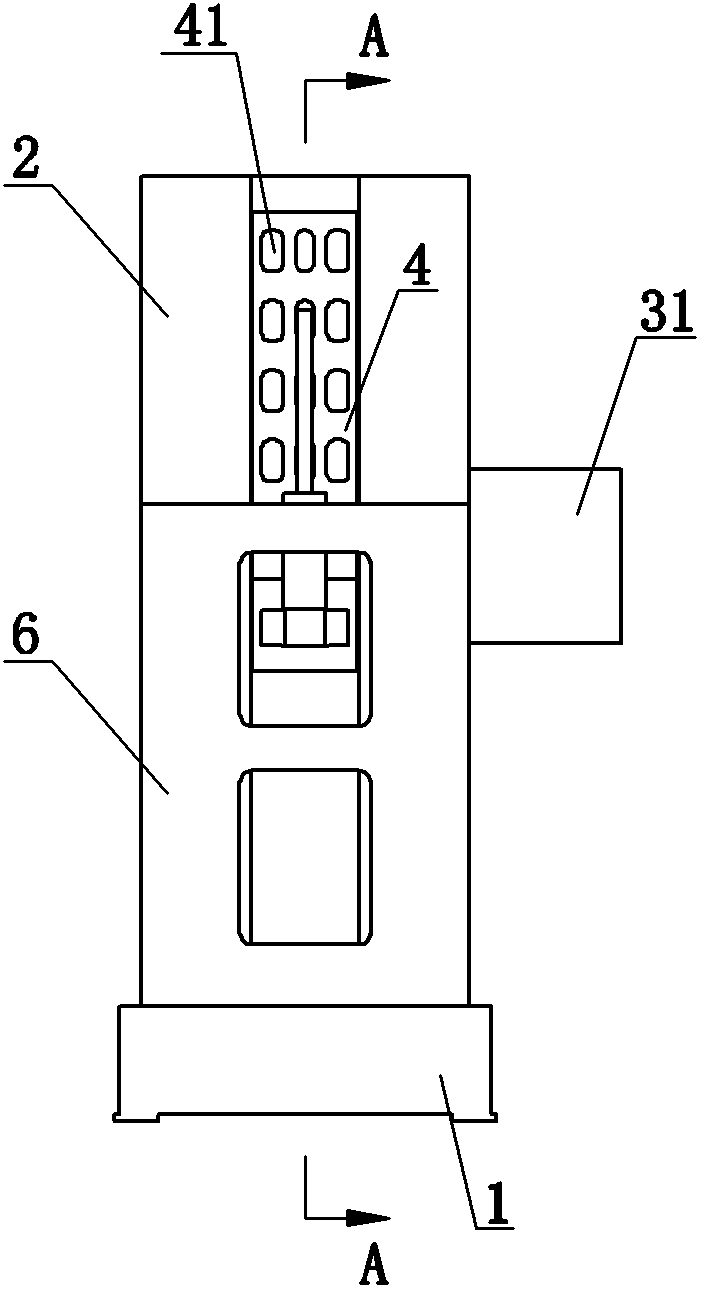

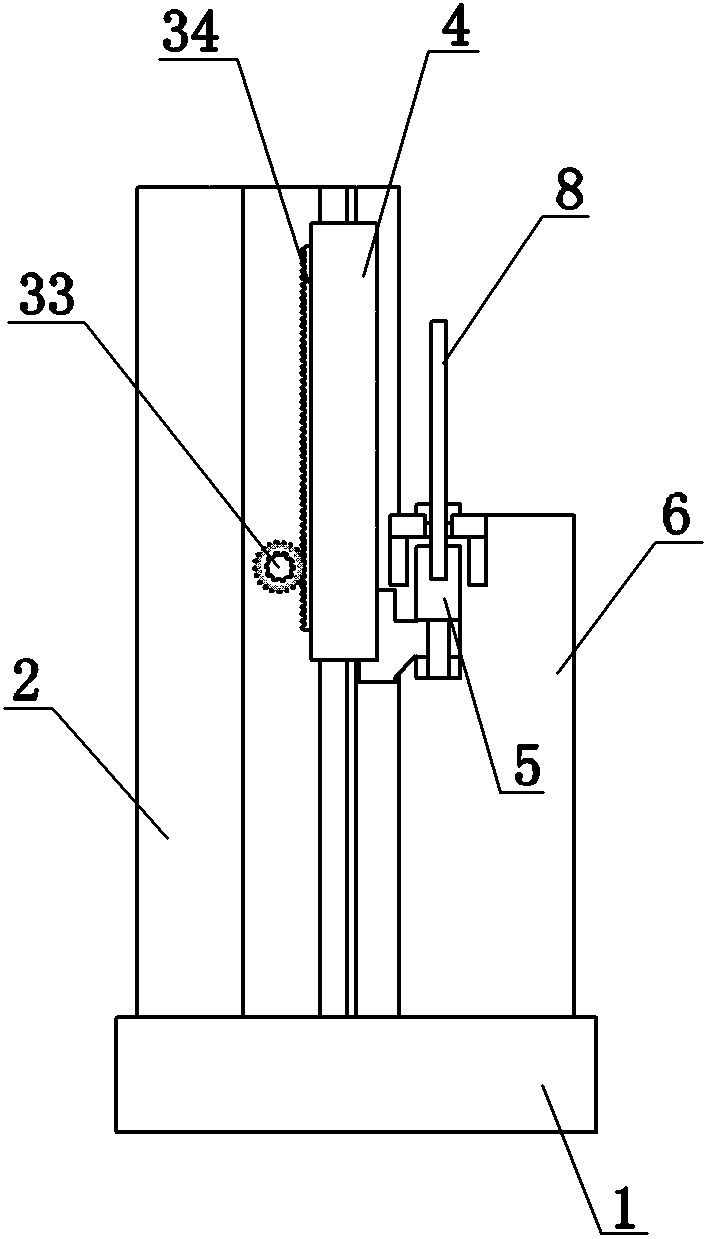

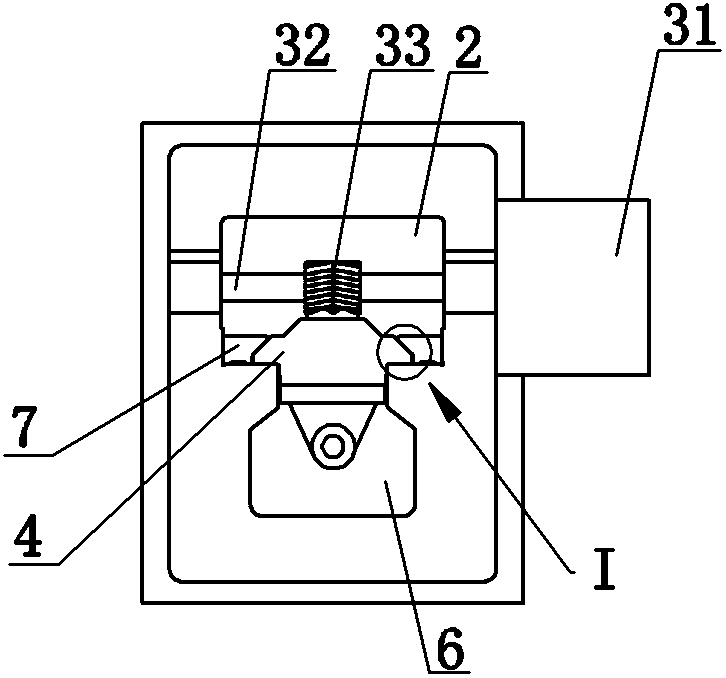

[0018] Such as figure 1 , figure 2 and image 3 Commonly shown is a structural schematic diagram of a heavy-duty gear-driven vertical broaching machine tool, which includes a base 1 and a bed 2 fixed on the base 1, and the bed 2 is provided with guide rails 7 extending vertically In the guide rail 7, there is a main sliding plate 4 which is adapted to it and can slide linearly back and forth along its extension direction. The main sliding plate 4 is driven by a power device, and the power device described here includes a motor 31, The drive shaft 32 connected to the output end of the motor 31, the drive gear 33 fixed on the drive shaft 32 and the drive rack 34 fixed on the main slide plate 4, the drive gear 33 and the drive rack 34 The drive gear 33 is preferably a herringbone gear, and the drive rack 34 is a herringbone rack that is compatible with the drive gear 33; The clamping device 5 of 8 is also provided with a workbench 6 for supporting the workpiece on the base 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com