High surface area mesoporous-micropore composite BETA zeolite and preparation method thereof

A technology with high specific surface area and specific surface area, which is applied in the field of zeolite materials, can solve the problems of reducing the synthesis cost of BETA zeolite, narrow synthesis phase zone, and low silicon-aluminum ratio of the product, so as to achieve controllable particle size, simple process and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

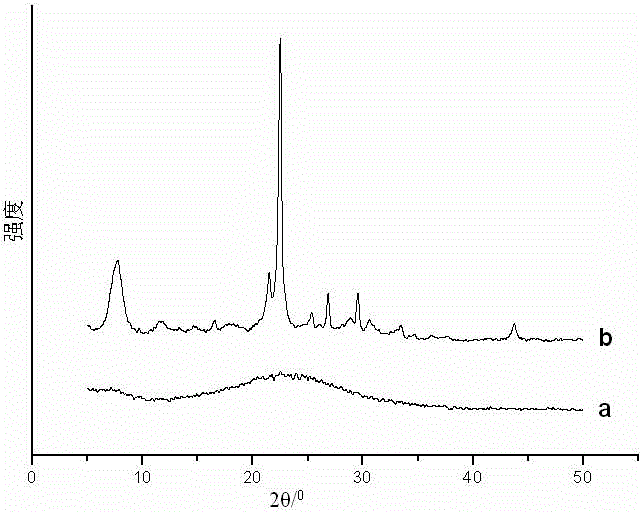

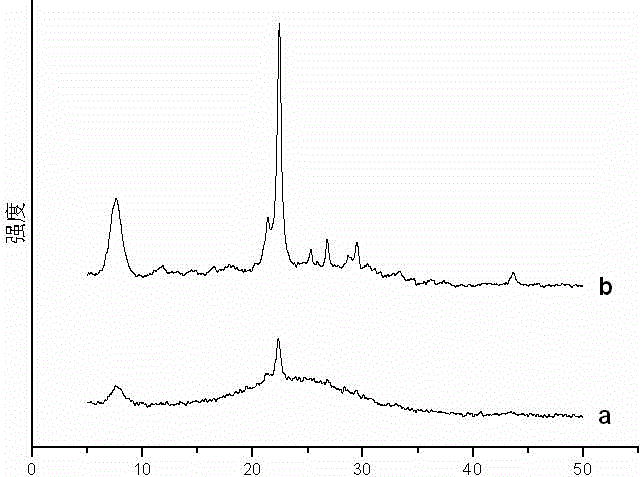

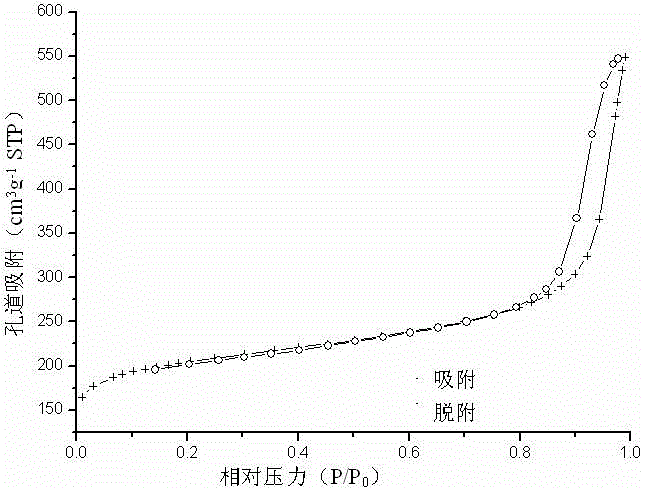

Image

Examples

Embodiment Construction

[0033] Further describe the present invention by embodiment below:

[0034] 1. Raw material ratio (see table below)

[0035] Numbering raw material Raw material / SiO 2 1 Silicon source: white carbon black, silica gel, water glass, silica sol, tetraethyl orthosilicate 1 2 Aluminum source: aluminum sulfate, aluminum nitrate, aluminum hydroxide 0~0.023 3 Alkali: Sodium Hydroxide 0.22~0.42 4 Organic template agent (TEAOH) 0.08~0.4 5 water 9.4 6 BETA zeolite seed 0~0.1

[0036] 2. Synthetic steps

[0037] With ingredients ratio 1SiO 2 :0.023Al 2 o 3 :0.42NaOH:0.1TEAOH:9.4H 2 O Seed / SiO 2 =10wt%; the silicon source is white carbon black; the aluminum source is aluminum sulfate octadecahydrate as an example.

[0038] (1) Weigh Al 2 (SO 4 ) 3 18H 2 O 1.532g, NaOH 1.68g, 25%TEAOH 5.888g were poured into a plastic cup.

[0039] (2) Weigh H2 O 12.462g in a plastic cup, stir with a plastic stirring rod to make Al 2 (S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com