Device for treating ammonia nitrogen waste water and method for degrading ammonia nitrogen waste water by using device

A technology of ammonia nitrogen wastewater and treatment device, which is applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of large and complicated stripping devices, high investment and operating costs, and large gas consumption and other problems, to achieve the effects of high ammonia nitrogen removal efficiency, low investment and operating costs, and lower wastewater temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

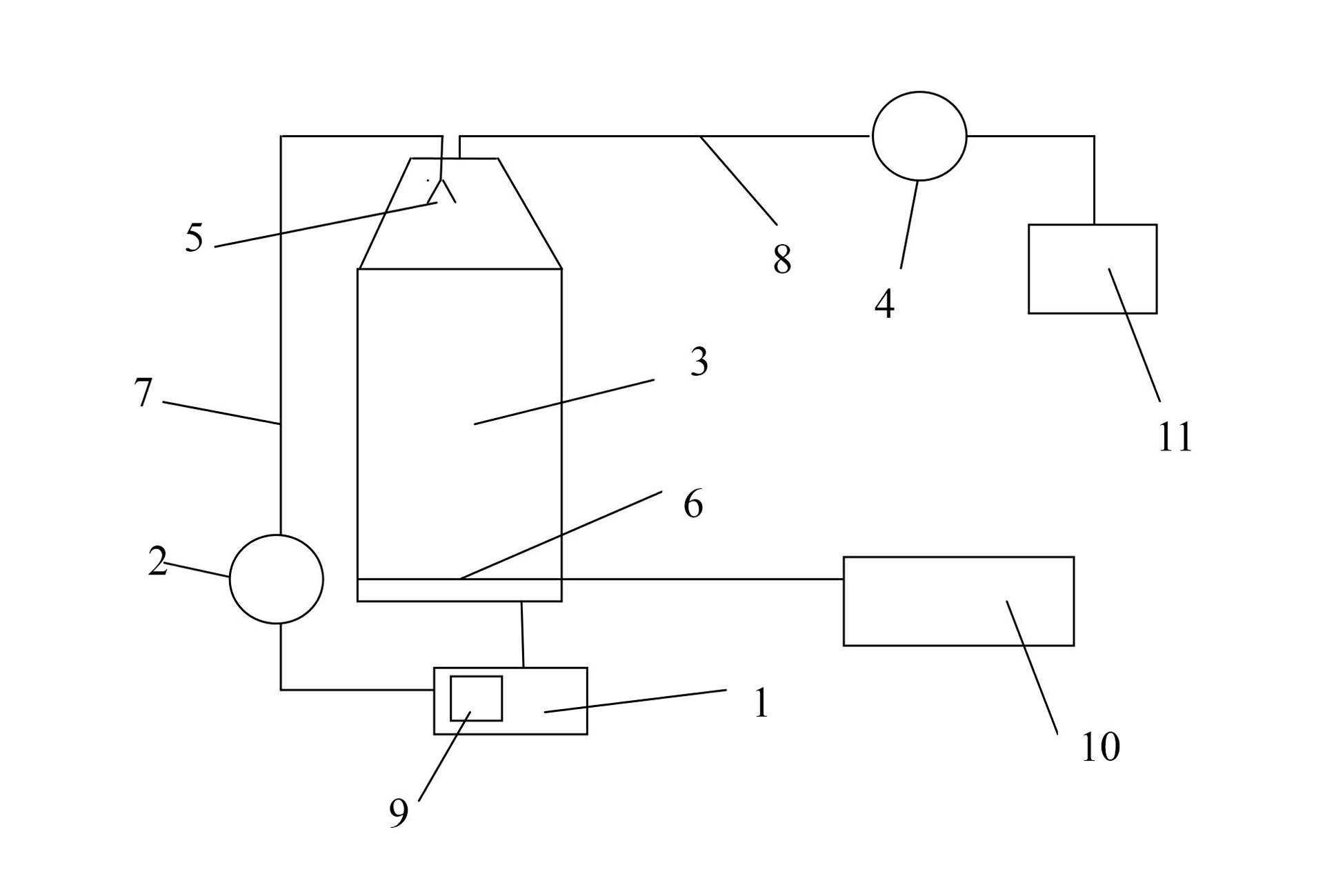

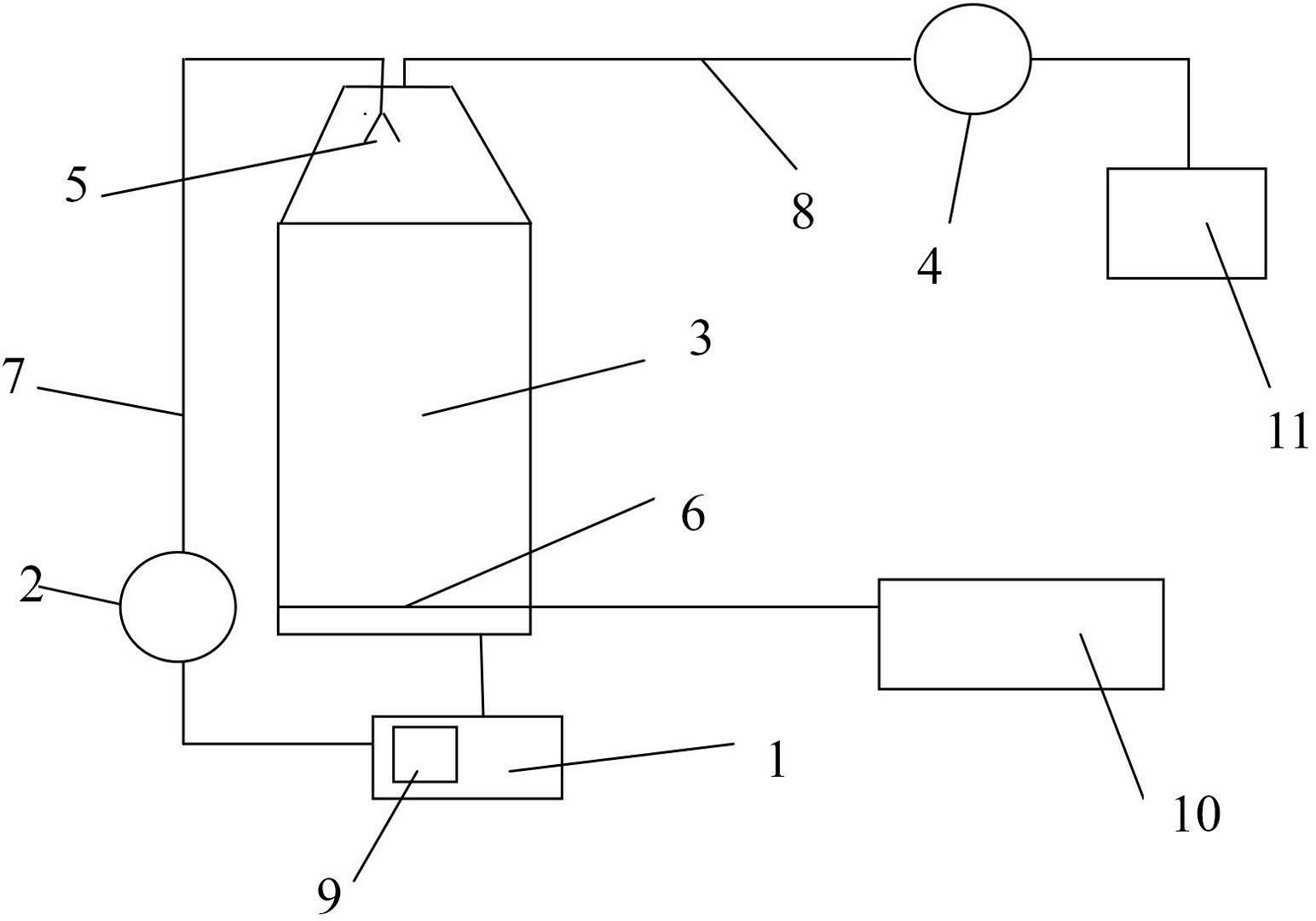

[0027] a kind of like figure 1 The shown ammonia nitrogen waste water treatment device of the present invention, this device comprises interconnected pretreatment device 10 and supersonic flash tower 3, the bottom of this supersonic flash tower 3 is communicated to the top of supersonic flash tower 3 by liquid circulation system . The liquid flow circulation system includes a liquid flow conveying pipeline 7 connecting the bottom of the ultrasonic flash tower 3 with the top, the liquid flow conveying pipeline 7 is provided with a circulating pump 2 and a liquid storage tank 1, and the outlet of the liquid flow conveying pipeline 7 is provided with a Nozzle 5. A heater 9 is arranged in the liquid storage tank 1 (a heating pipe can also be installed on the liquid flow delivery pipeline 7). The top of the ultrasonic flash tower 3 is also connected with a gas export device, which includes a gas delivery pipeline 8 drawn from the top of the ultrasonic flash tower 3 and a vacuum p...

Embodiment 2

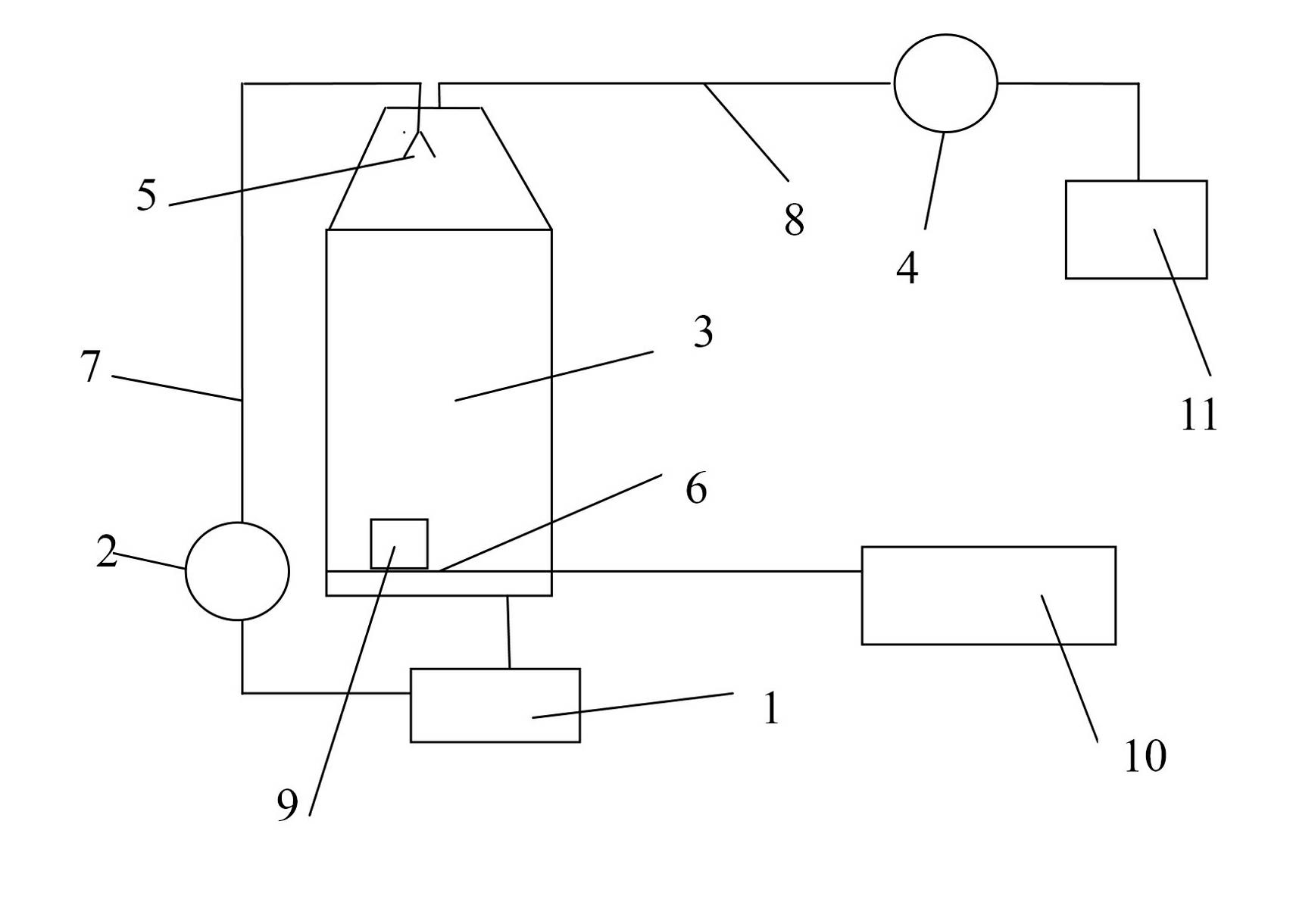

[0036] a kind of like figure 2 The shown ammonia nitrogen waste water treatment device of the present invention, this device comprises interconnected pretreatment device 10 and supersonic flash tower 3, the bottom of this supersonic flash tower 3 is communicated to the top of supersonic flash tower 3 by liquid circulation system . The liquid flow circulation system includes a liquid flow conveying pipeline 7 connecting the bottom of the ultrasonic flash tower 3 with the top, the liquid flow conveying pipeline 7 is provided with a circulation pump 2 and a liquid storage tank 1, and the outlet of the liquid flow conveying pipeline 7 is provided with a Nozzle 5. The top of the ultrasonic flash tower 3 is also connected with a gas export device, which includes a gas delivery pipeline 8 drawn from the top of the ultrasonic flash tower 3 and a vacuum pump 4 installed on the gas delivery pipeline 8, and the gas export device is connected with Ammonia recovery unit 11. An ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com