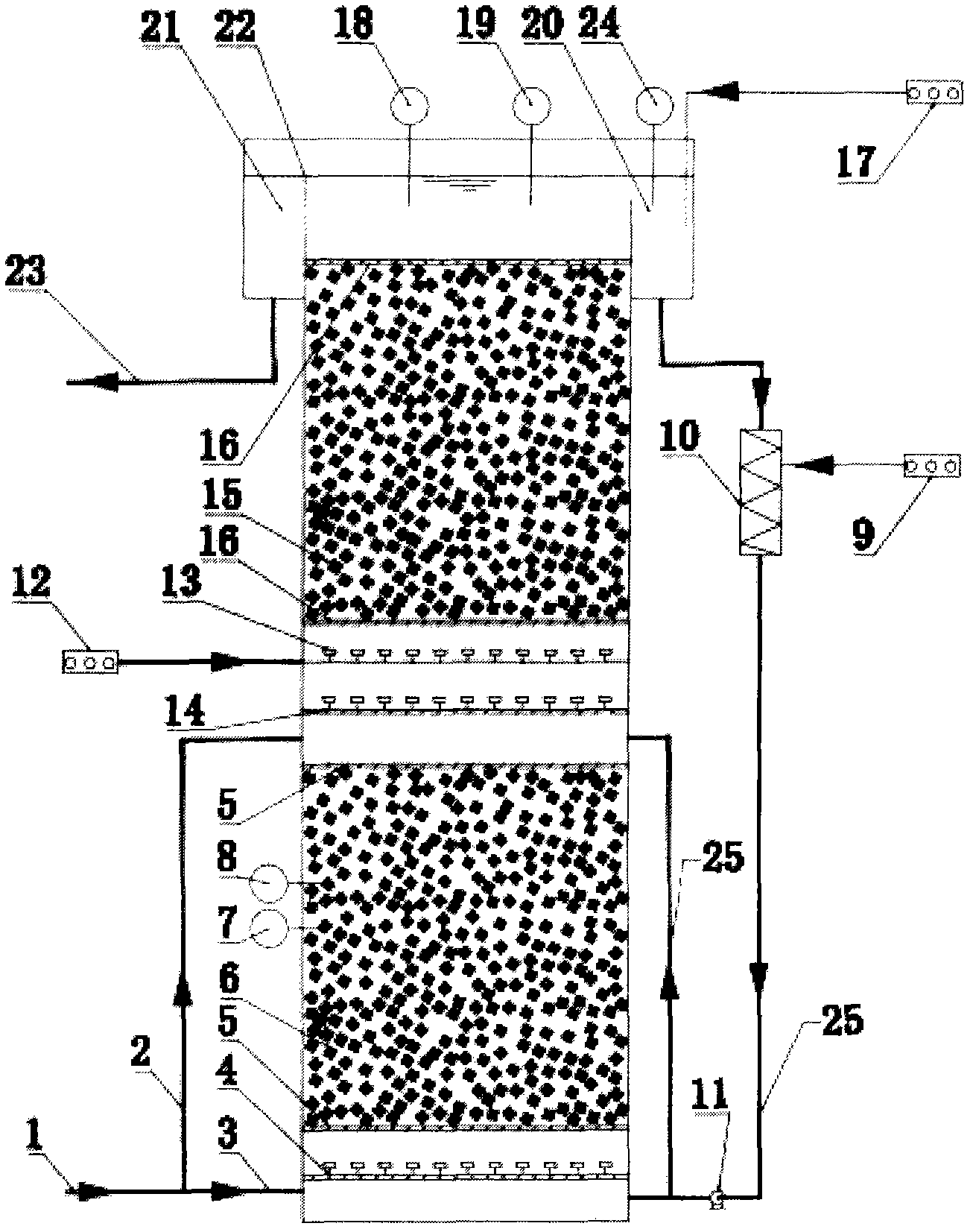

Two-segment aerobic-anaerobic ammonia oxidization reactor

An anaerobic ammonium oxidation and reactor technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of long start-up time, increased treatment cost, and nitrifying bacteria proliferation Slow speed and other problems, to achieve the effect of improving impact resistance, strengthening contact and mass transfer, and being beneficial to engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

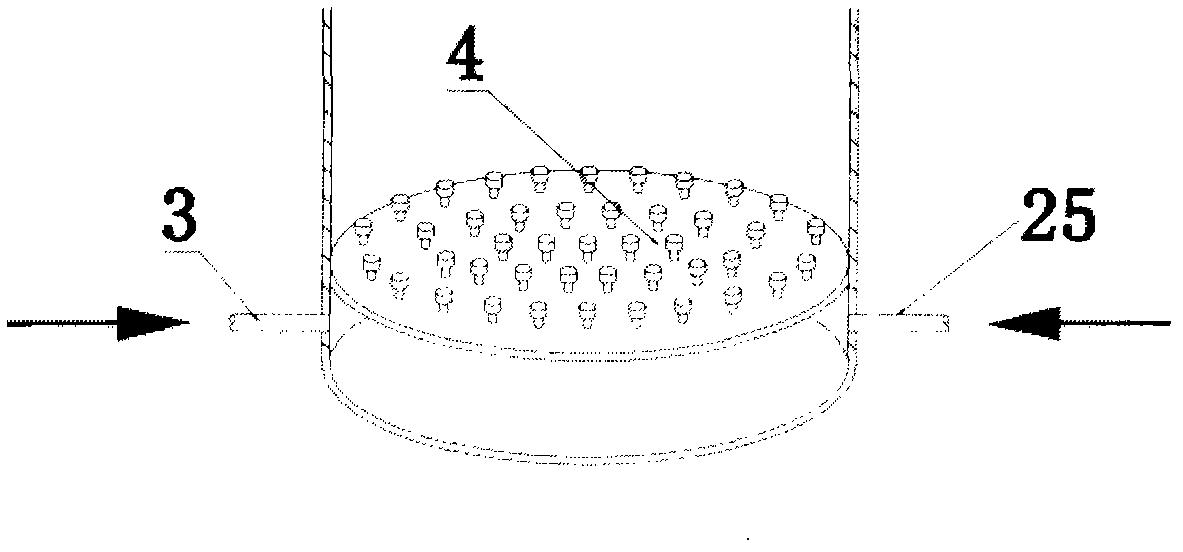

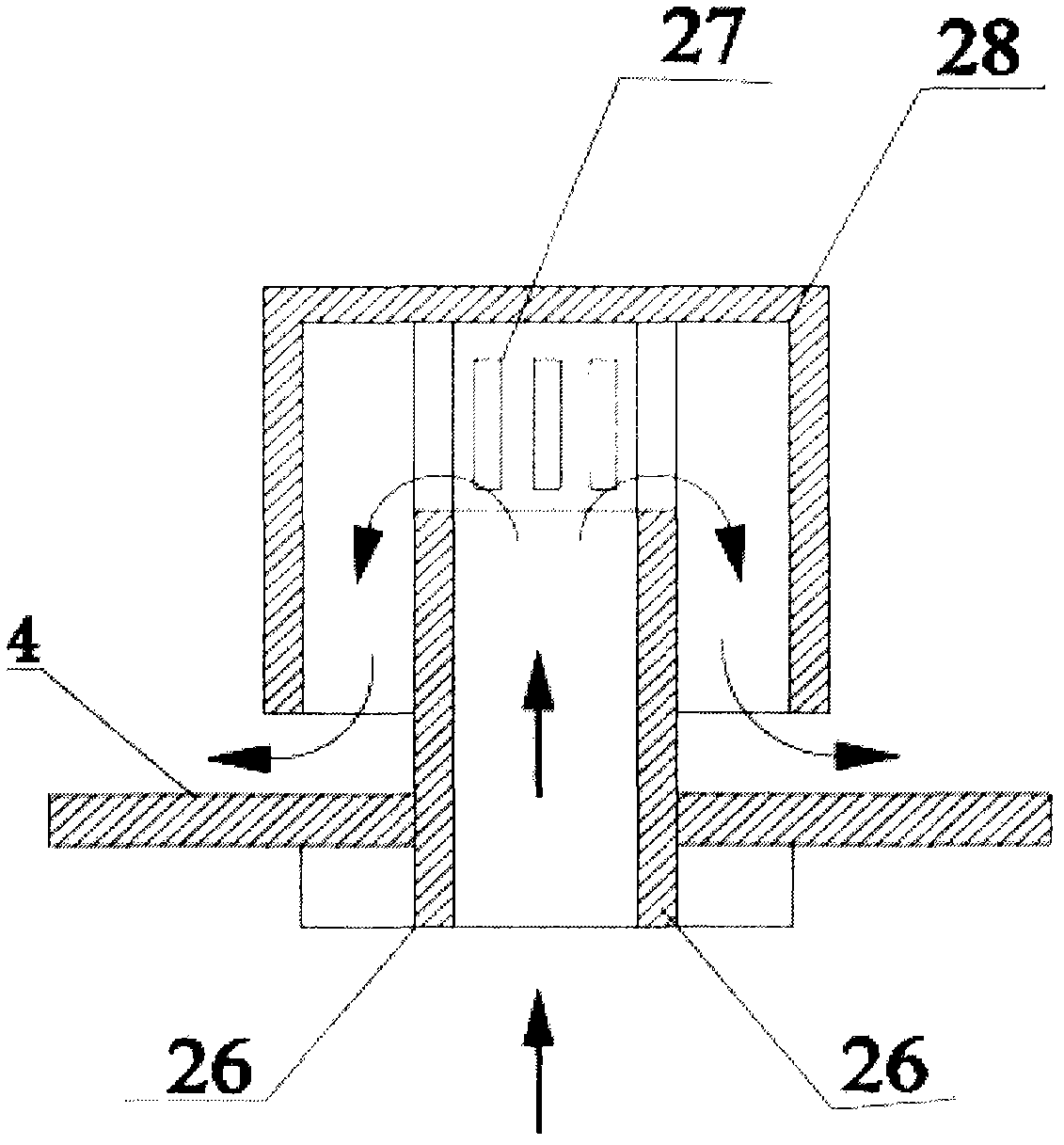

Method used

Image

Examples

Embodiment 1

[0057]The effluent of landfill leachate anaerobic reactor, (implementation process is the same as above) ammonia nitrogen is 18502-230mg.L -1 , CODcr is 1430-2120mg.L -1 , BOD3 is 211 317mg.L -1 ;

[0058] Anaerobic section HRT=16h, T=36-38℃, pH=7.50, DO=0mg.L -1 ;

[0059] Aerobic stage HRT=12h, water temperature T=34-36℃, pH=7.20, DO=0.60.8mg.L -1 ; The conversion rate of nitrite in the aerobic section is greater than 98%, and the average concentration of ammonia nitrogen in the effluent is 95mg.L -1 , TN average concentration 225mg.L -1 .

Embodiment 2

[0061] The effluent of the aquaculture wastewater anaerobic reactor, (the implementation process is the same as above) the ammonia nitrogen is 720-852mg.L -1 ; Anaerobic section HRT=12h, T=36-38℃, pH=7.40-7.60, DO=0mg.L -1 ;

[0062] Aerobic stage HRT=8h, water temperature T=34-36℃, pH=7.20-7.50, DO=0.6-0.8mg.L -1 , the conversion rate of nitrite in the aerobic section is greater than 99%, and the average concentration of ammonia nitrogen in the effluent is 25mg.L -1 , TN average concentration 64mg.L -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com