Cellulose fiber for concrete

A cellulose fiber and concrete technology, applied in the field of cellulose fiber, can solve problems such as fiber dispersion, affecting fiber application, and affecting concrete construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

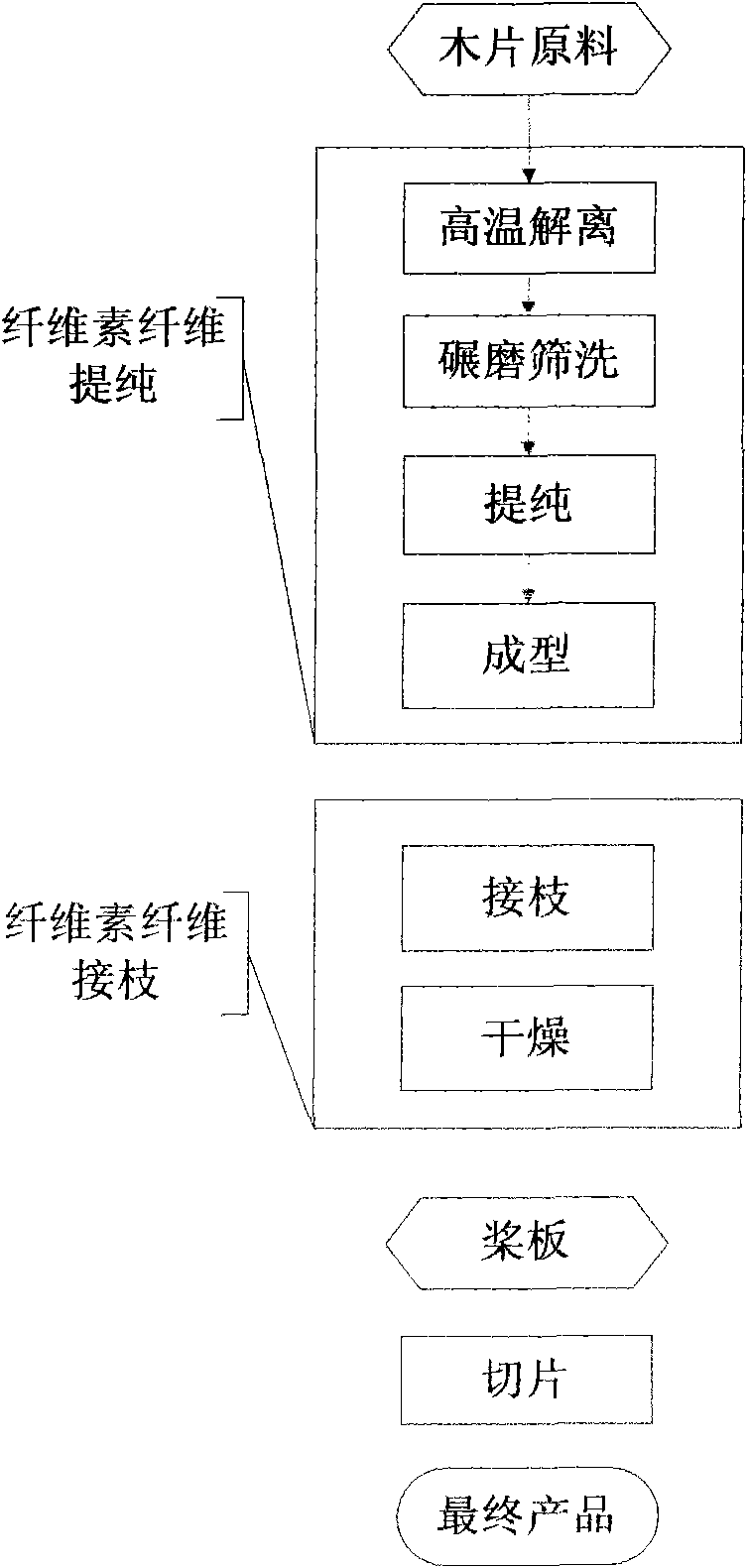

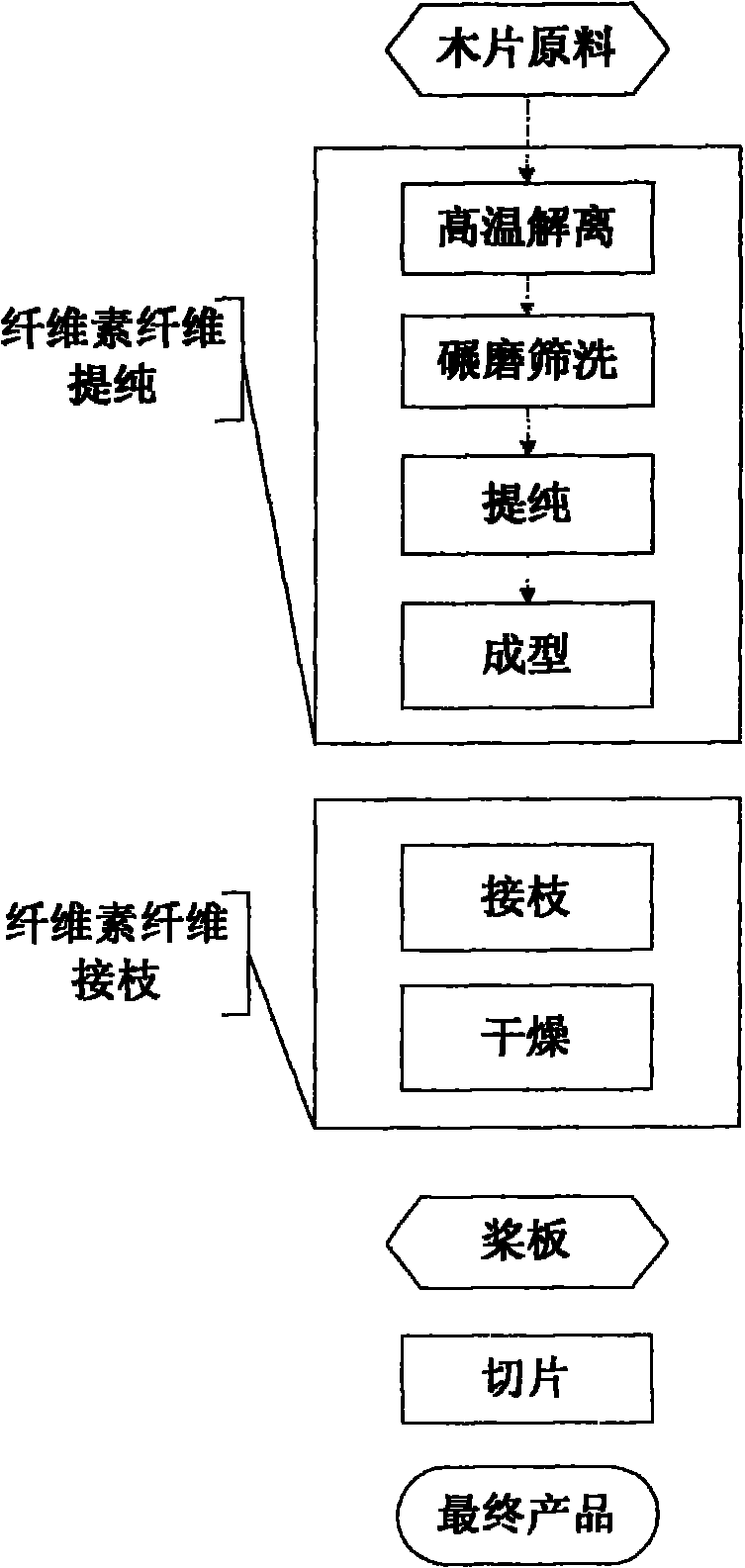

[0018] The cellulose fiber raw material of the present invention selects coniferous wood, and takes coniferous medium and small-diameter materials such as southern fir and masson pine as raw materials, and obtains wood chips with a length of 20 ± 5 mm in the direction of wood grain, a width greater than 3 mm, and a thickness of 5 ± 1 mm by peeling and slicing. Raw materials; the cellulose fiber preparation process is as follows:

[0019] The first step: high temperature dissociation

[0020] Fill the pressure vessel with wood chips and add enough chemical solution composed of sodium hydroxide and sodium sulfide (the degree of sulfide is 30±5%) to cover the wood chips, heat to 160±10°C, and keep warm for 2-3 hours.

[0021] Step 2: Grinding and sifting

[0022] The high-temperature dissociated slurry is further dissociated from fibers by a disc refiner, and is purified by sieve washing to form a slurry with a concentration of 1% to 5%.

[0023] The third step: purification

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com