Method for extraction and separation purification of blumea balsamifera (L.)DC. sheets

A technology for separation and purification of escarpone, applied in the field of extraction, separation and purification of escarpone, can solve the problems of high operating temperature of distillation and sublimation equipment, low extraction efficiency, high labor intensity, etc., so as to reduce transformation or degradation, fully extract and save materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

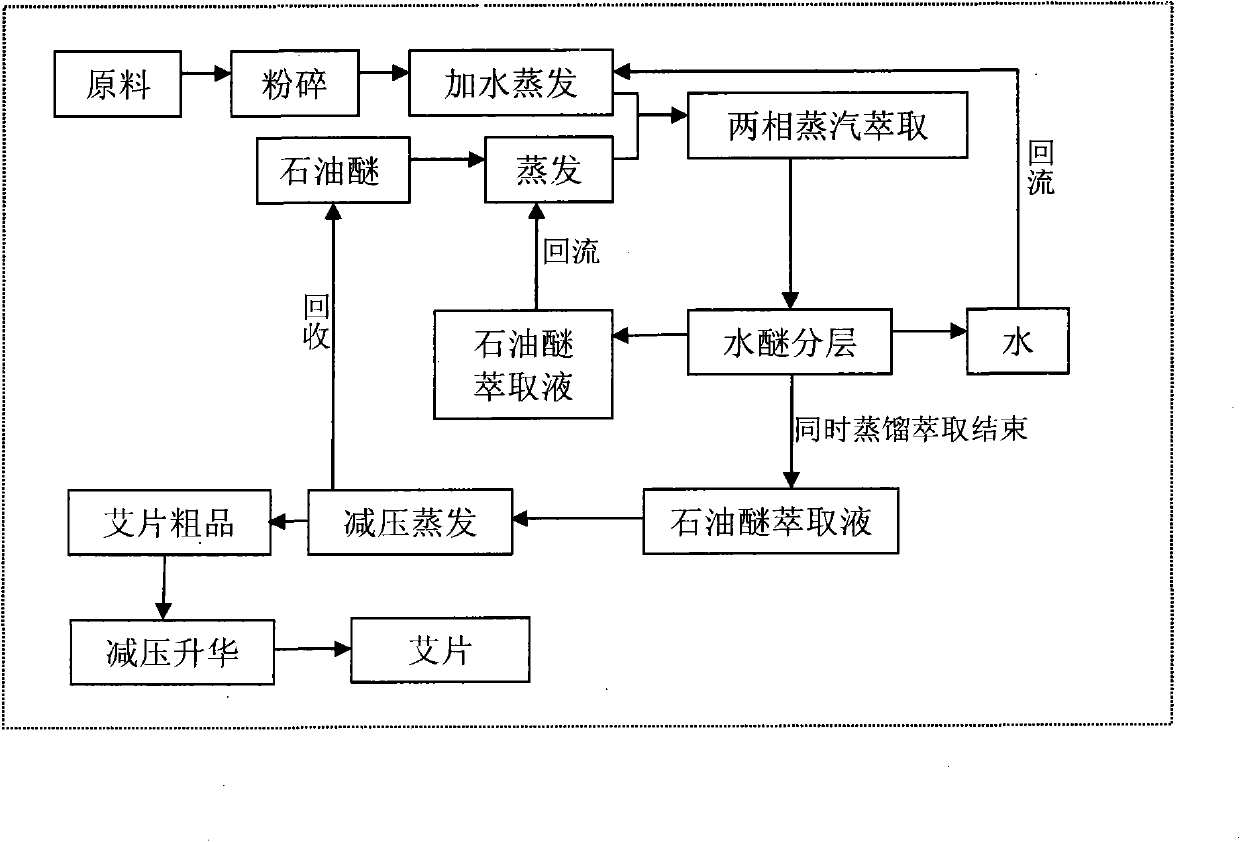

[0019] A method for extracting, separating and purifying moxa tablets of the present invention adopts the following process steps:

[0020] 1. Simultaneous distillation and extraction: crush the leaves and twigs of Ainaxiang powder into Ainaxiang powder, with a particle size of 0.1-1mm. Add 50g of the pulverized Ainaxiang powder into 1L of water, heat to a slight boil to generate water vapor , while heating 100mL of petroleum ether (boiling range 30-60°C) to slightly boil to produce petroleum ether vapor, when the two-phase steam meets, the petroleum ether vapor extracts the fat-soluble volatile components carried by the water vapor, and the two are condensed in the condenser at the same time, due to the water The incompatibility with petroleum ether separates the two, wherein the distilled water phase is refluxed into the water bottle, and the petroleum ether phase is refluxed into the petroleum ether bottle. The whole process takes 5 hours to obtain the Ainaxiang petroleum et...

Embodiment 2

[0025] A method for extracting, separating and purifying moxa tablets of the present invention adopts the following process steps:

[0026] 1. Simultaneous distillation and extraction: crush the leaves and twigs of Ainaxiang powder into Ainaxiang powder with a particle size of 0.1-1mm, add 5kg of crushed Ainaxiang powder into 5L of water, and heat to a slight boil to generate water vapor , while heating 1L of petroleum ether (boiling range 30-60°C) to slightly boil to generate petroleum ether vapor. When the two-phase steam meets, the petroleum ether vapor extracts the fat-soluble volatile components carried by the water vapor, and the two are condensed in the condenser at the same time. The incompatibility with petroleum ether separates the two, wherein the distilled water phase is refluxed into the water bottle, and the petroleum ether phase is refluxed into the petroleum ether bottle. The whole process takes 10 hours to obtain the Ainaxiang petroleum ether extract;

[0027]...

Embodiment 3

[0030] A method for extracting, separating and purifying moxa tablets of the present invention adopts the following process steps:

[0031] 1. Simultaneous distillation and extraction: crush the leaves and twigs of Ainaxiang powder into Ainaxiang powder, with a particle size of 0.1-1mm. Add 10kg of the pulverized Ainaxiang powder into 10L of water, heat to a slight boil to generate water vapor , while heating 1L of petroleum ether (boiling range 30-60°C) to slightly boil to generate petroleum ether vapor. When the two-phase steam meets, the petroleum ether vapor extracts the fat-soluble volatile components carried by the water vapor, and the two are condensed in the condenser at the same time. The incompatibility with petroleum ether separates the two, wherein the distilled water phase is refluxed into the water bottle, and the petroleum ether phase is refluxed into the petroleum ether bottle. The whole process takes 10 hours to obtain the Ainaxiang petroleum ether extract;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com