Synthetic method of amino-substituted cyclohexyl crown ether

The technology of a radical crown ether and a synthesis method, which is applied in the synthesis field of amino group-substituted cyclohexyl crown ether, can solve the problems of high catalyst cost, harsh reaction conditions, cumbersome steps, etc., and achieves low catalyst dosage, reaction temperature and pressure. The effect of mild conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

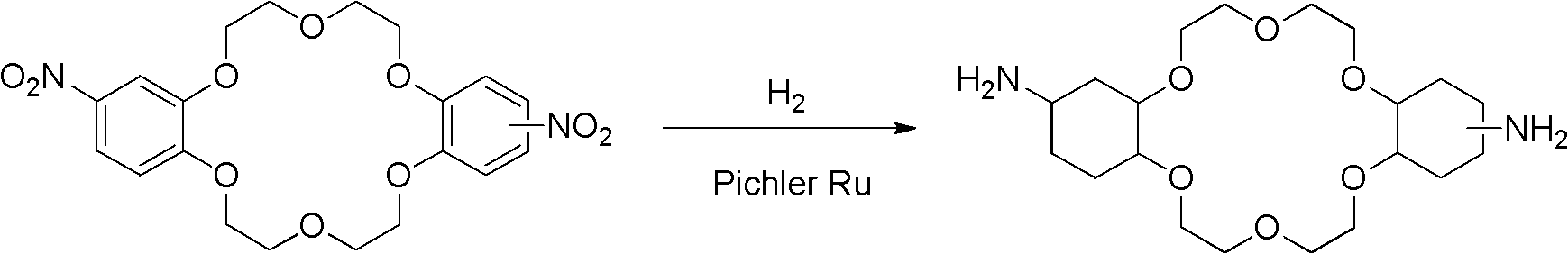

[0018] Example 1: Synthesis of diaminodicyclohexyl-18-crown-6

[0019] Using dinitrodibenzo-18-crown-6 as a substrate, under the action of Pichler ruthenium catalyst, the reaction equation for the one-step synthesis of diaminodicyclohexyl-18-crown-6 using high-pressure hydrogen is as follows:

[0020]

[0021] Dissolve 5.0 g of dinitrodibenzo-18-crown-6 in 450 mL of ethanol and add it to an autoclave with a volume of 3L. Weigh 1 g of the newly activated Pichler ruthenium catalyst, disperse it in 50 mL of ethanol, and add it to the kettle. The reactor was closed and locked, the air in the kettle was replaced by nitrogen gas three times, and the nitrogen gas was replaced by hydrogen gas three times, and then hydrogen gas with a pressure of 6 MPa was introduced. Keep stirring, control the temperature in the kettle to 100°C, stop the reaction after 8 hours of reaction, and release the pressure after the entire system is cooled. Filtration, separation and recovery of Pichler ruthenium...

Embodiment 2

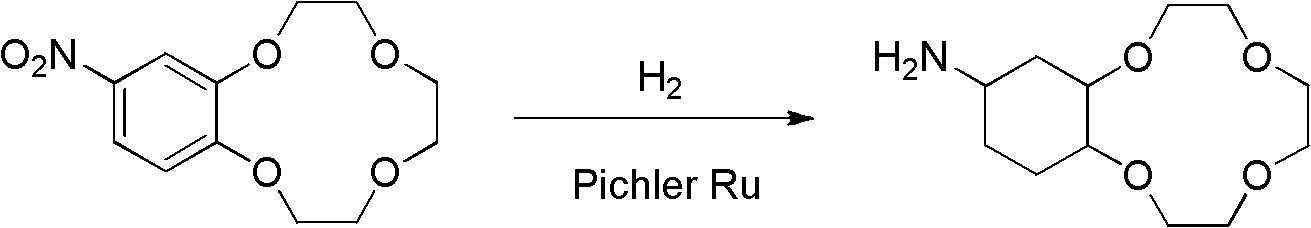

[0022] Example 2: Synthesis of amino-substituted cyclohexyl-12-crown-4

[0023] Under the action of Pichler ruthenium catalyst, mononitro substituted benzo-12-crown-4 uses high-pressure hydrogen to react in one step to generate amino-substituted cyclohexyl-12-crown-4. The reaction equation is as follows:

[0024]

[0025] Weigh 10.0 g of nitro-substituted benzo-12-crown-4 and dissolve in 700 mL of n-butanol in a 3L autoclave. Weigh 0.8 g of newly activated Pichler ruthenium catalyst, disperse it in 100 mL of n-butanol, and add it to the kettle. The reactor was closed and locked, the air in the kettle was replaced by nitrogen gas three times, and the nitrogen gas was replaced by hydrogen gas three times, and then hydrogen gas with a pressure of 7 MPa was introduced. Keep stirring, control the temperature in the kettle to 85°C, stop the reaction after 10 hours of reaction, and release the pressure after the entire system is cooled. Filtration, separation and recovery of Pichler rut...

Embodiment 3

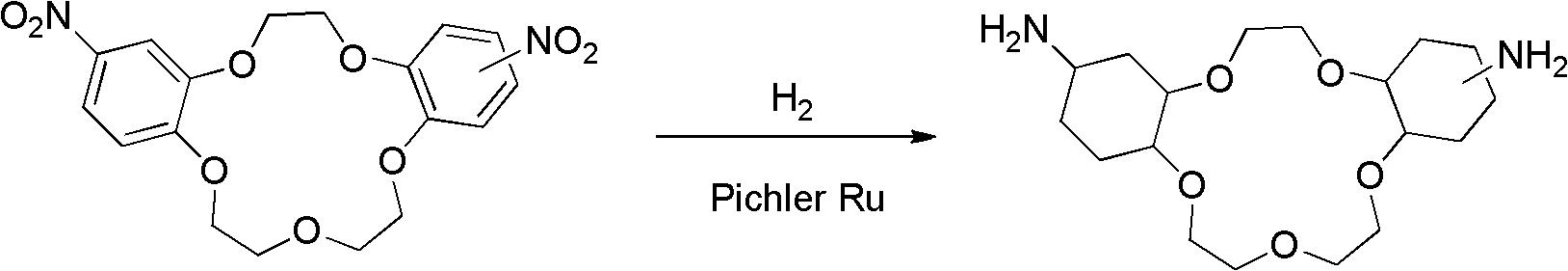

[0026] Example 3: Synthesis of diaminodicyclohexyl-15-crown-5

[0027] Under the action of Pichler ruthenium catalyst, use high pressure hydrogen to reduce dinitrodibenzo-15-crown-5 in one step to produce diaminodicyclohexyl-15-crown-5. The reaction equation is as follows:

[0028]

[0029] Dissolve 5.0 g of dinitrodibenzo-15-crown-5 in 300 mL of ethylene glycol dimethyl ether and add it to an autoclave with a volume of 1 L. Weigh 0.3 g of newly activated Pichler ruthenium catalyst, disperse it in 50 mL of ethylene glycol dimethyl ether, and add it to the kettle. The reactor was closed and locked, the air in the kettle was replaced by nitrogen gas three times, and the nitrogen gas was replaced by hydrogen gas three times, and then hydrogen gas with a pressure of 9 MPa was introduced. Keep stirring, control the temperature in the kettle to 110°C, stop the reaction after 5 hours, and release the pressure after the entire system cools down. After filtering, separating and recovering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com