UV cured metallic paint for plastics

A metal texture and coating technology, applied in the field of coatings, can solve the problems of no coloring, no decoration on the plastic surface, no color, etc., and achieve the effects of fast curing speed, energy saving and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

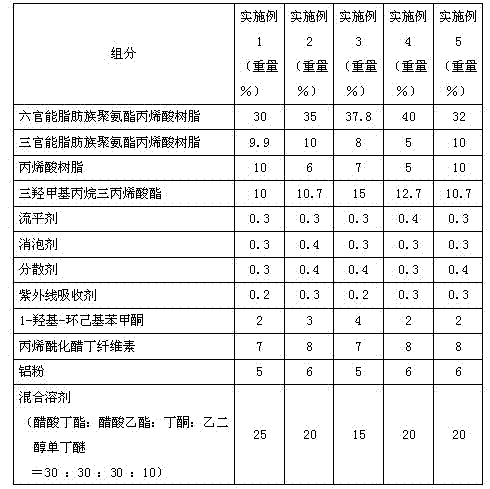

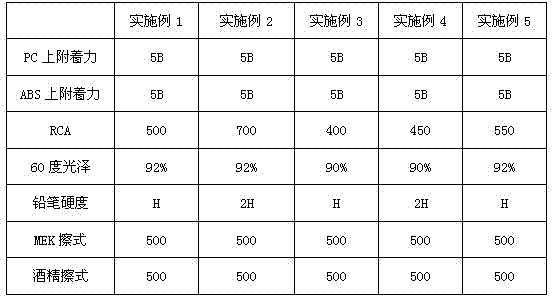

[0047] through as figure 1 Shown embodiment 1-5 is described in further detail to the present invention as follows: wherein, described hexafunctional urethane acrylic resin is aliphatic urethane acrylic resin, and its molecular weight is 1000, and solid content is 100%, and elongation is 4%, The tensile strength is 9100Psi; it can provide excellent hardness and wear resistance for coating. The trifunctional polyurethane acrylic resin is an aliphatic polyurethane acrylic resin with a molecular weight of 2000 and a solid content of 100%. The elongation rate is 37%, and the tensile strength is 4200Psi; it can improve the impact resistance of the coating. The acrylic resin contained 25% tripropylene glycol diacrylate and 25% 1.6 hexanediol diacrylate, had an elongation of 52%, and a tensile strength of 1900 Psi; providing excellent adhesion to the coating.

[0048] At the same time, the defoamer is organic silicon, specifically a foam-breaking polymer and organopolysiloxane solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com