Precisely controlled biomass gas and biomass carbon preparation system

A biomass gas and biomass char technology, which is applied in the fields of biofuel, special form dry distillation, petroleum industry, etc., can solve the problems of no material height control, small size, poor reliability, etc., and achieves a high level of automation, wide application fields, Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

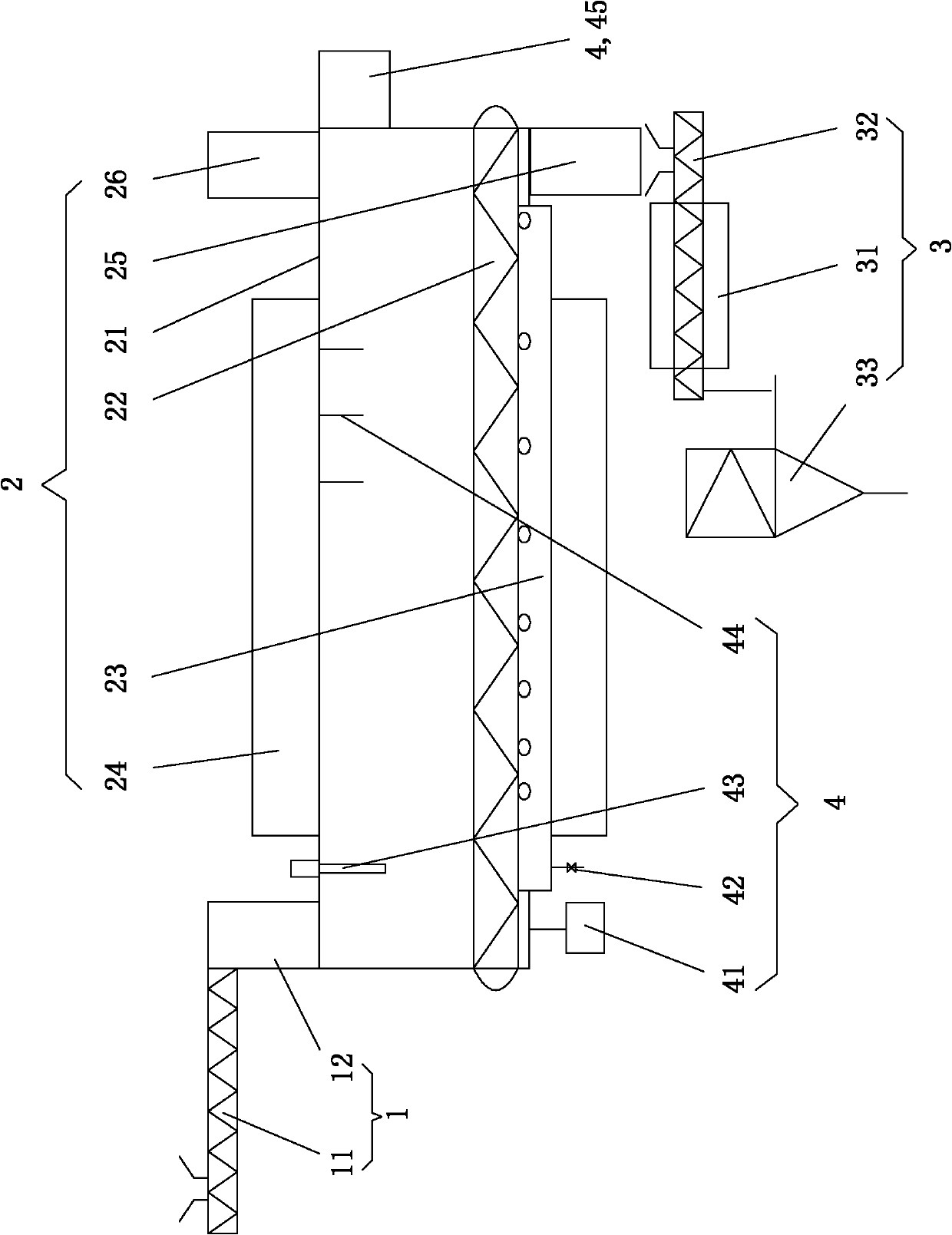

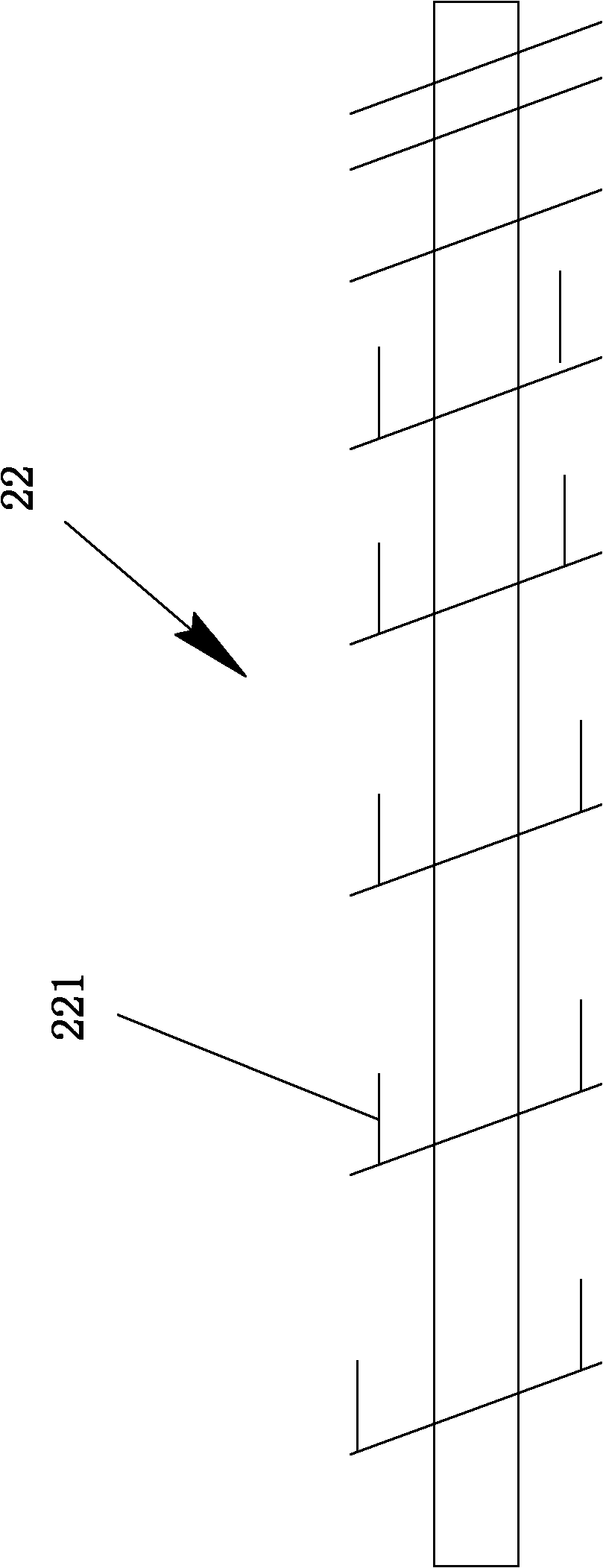

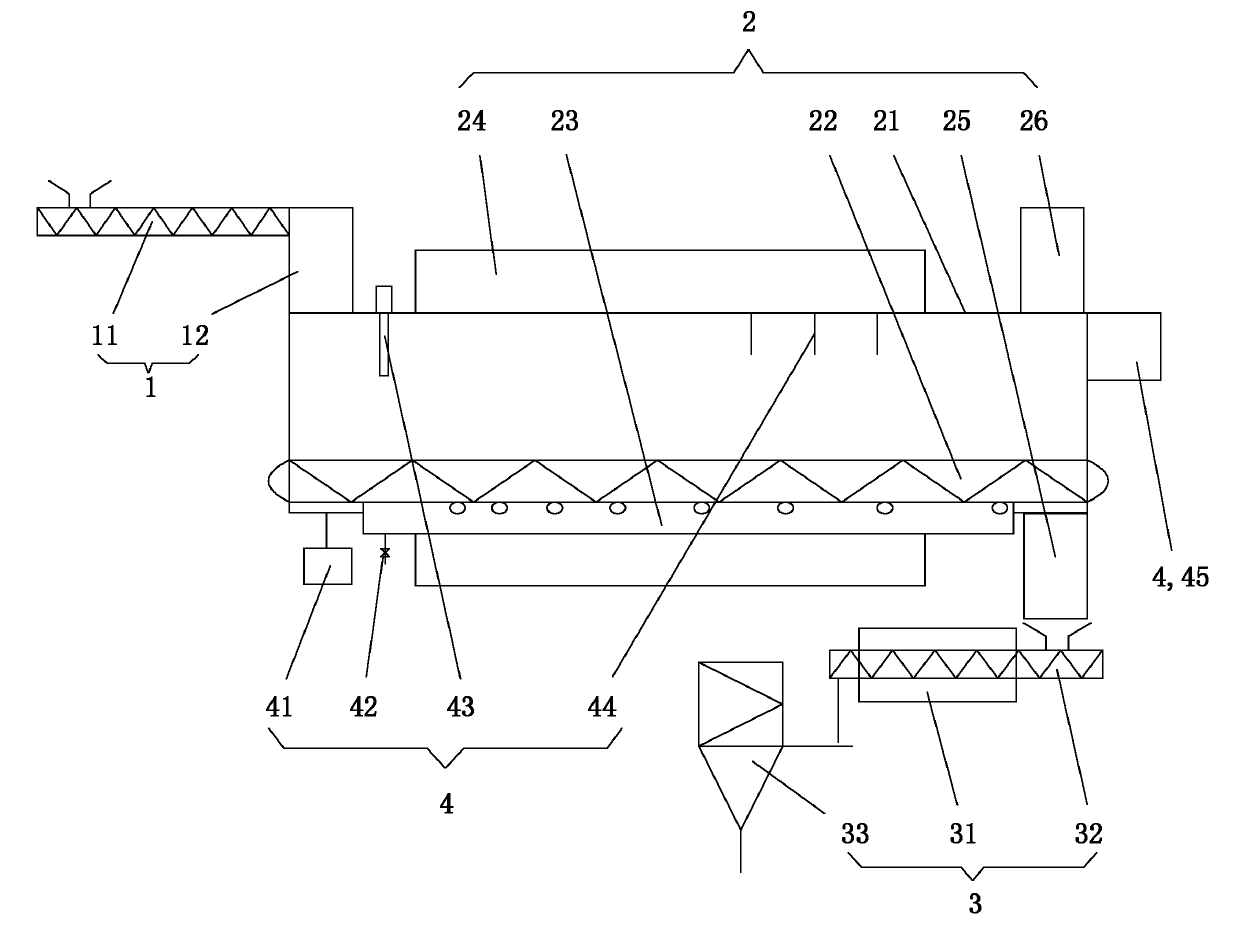

[0052] The precisely controlled biomass gas and biomass char preparation system has a pyrolysis reaction body 21, the front end of which is connected to the feed bin 12, and the rear end has two outlets, namely the upper biomass gas outlet 26 and the lower biomass gas outlet. The charcoal discharge port 25, the feed bin 12 is connected with the screw feed device 11, the rear section of the screw of the screw feed device 11 has no screw, the biomass carbon discharge port 25 is connected with the screw discharge device 32, and the pyrolysis reaction body 21 The bottom is equipped with a double helix structure screw propulsion device 22, the screw blade is belt type and has horizontal rake teeth, the number of rake teeth is reduced in the high temperature area, hot air passes through the screw shaft, and the bottom of the pyrolysis reaction body 21 is equipped with an air supply device 23 At the bottom of the pyrolysis reaction body 21, there are holes at the bottom of the pyrolys...

Embodiment 2

[0071] In this embodiment, the screw propulsion device 22 of the pyrolysis reaction unit 2 adopts a single screw structure, and the rest is the same as that of Embodiment 1. The system of this embodiment is mainly aimed at heavy biomass raw materials, such as sawdust.

Embodiment 3

[0073] In this embodiment, there is no hot air jacket outside the pyrolysis reaction body 21, and there is no hot air inside the screw shaft of the screw propulsion device 22, which is suitable for some occasions without waste heat sources, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com