Laser heat treatment strengthening process

A laser heat treatment and process technology, applied in the field of laser applications, can solve the problems of many production processes and high production costs, and achieve the effects of saving processes, improving service life and improving processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

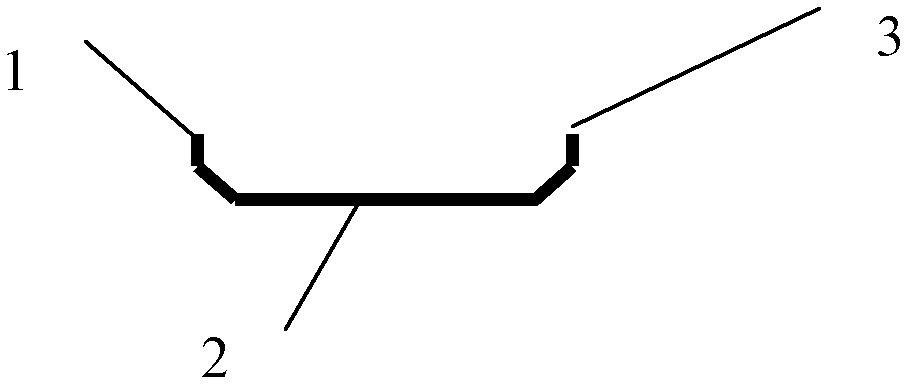

Image

Examples

Embodiment 1

[0021] For the processed wok with a diameter of 200 mm, the laser power is 1200 watts, the laser beam scanning speed is 15 mm / s, and the spot diameter is 2 mm. The laser makes the surface of the workpiece reach the melting temperature of the material, and the heat treatment time is 40 seconds, reaching Laser remelting refines the grain effect.

[0022] A pressure deformation test was carried out on the treated wok. Compared with the conventional treatment technology, the anti-deformation ability is equivalent, the heat treatment speed has been increased by 60%, and the production cost has been reduced. The surface hardness of the frying pan is HB=360, and the thickness of the surface nitrided layer and hardened layer is 0.6 mm.

Embodiment 2

[0024] For the processed wok with a diameter of 250 mm, the laser power is 1000 watts, the laser beam scanning speed is 10 mm / s, and the spot diameter is 3 mm. The laser makes the surface of the workpiece reach the melting temperature of the material, and the heat treatment time is 30 seconds, reaching Laser remelting refines the grain effect.

[0025] A pressure deformation test was carried out on the treated wok. Compared with the conventional treatment technology, the anti-deformation ability is equivalent, the heat treatment speed has been increased by 60%, and the production cost has been reduced. The surface hardness of the frying pan is HB=350, and the thickness of the surface nitrided layer and hardened layer is 0.5 mm.

Embodiment 3

[0027] For the processed wok with a diameter of 300 mm, the laser power is 1500 watts, the scanning speed of the laser beam is 20 mm / s, and the diameter of the spot is 1 mm. The laser makes the surface of the workpiece reach the melting temperature of the material, and the heat treatment time is 50 seconds.

[0028] A pressure deformation test was carried out on the treated wok. Compared with the conventional treatment technology, the anti-deformation ability is equivalent, the heat treatment speed has been increased by 60%, and the production cost has been reduced. The surface hardness of the frying pan is HB=400, and the thickness of the surface nitrided layer and hardened layer is 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com