Soft austenitic stainless steel and preparation method thereof

A technology of austenitic stainless steel and molten steel, applied in the field of stainless steel, to achieve the effect of excellent corrosion resistance and good deep processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

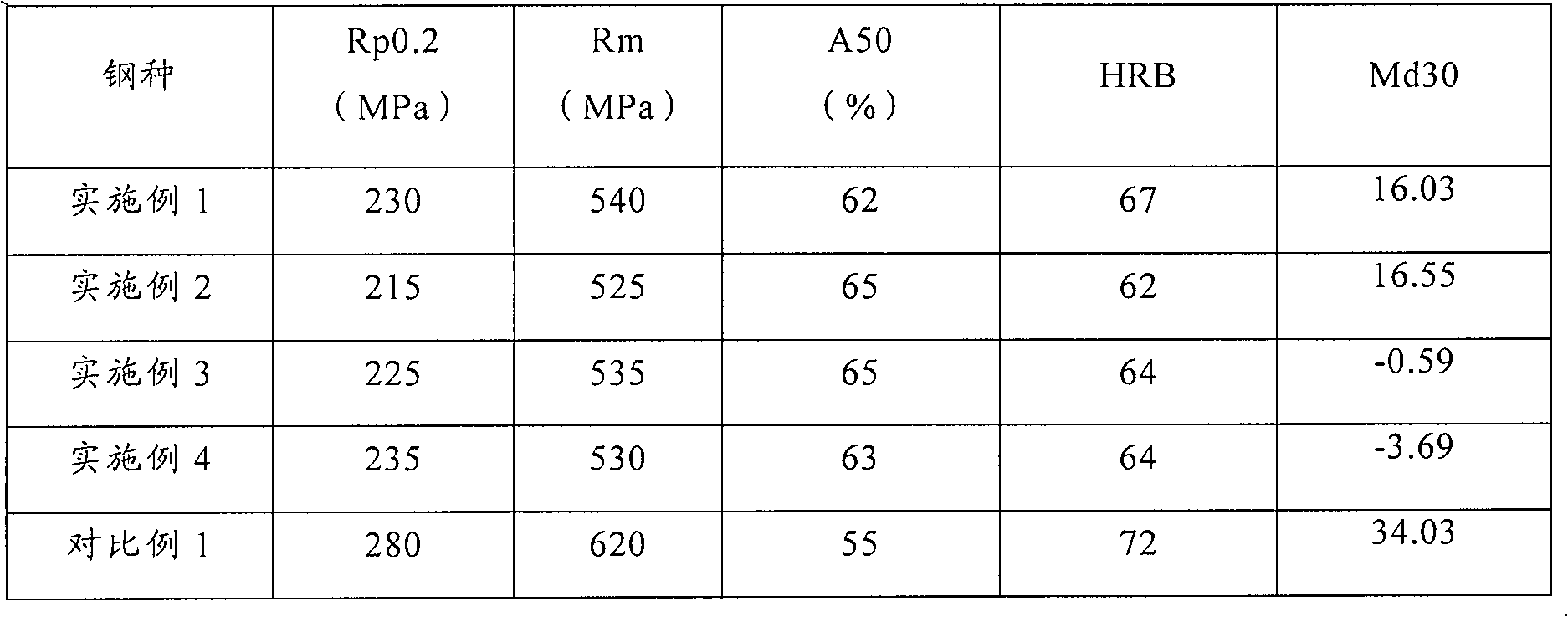

[0036] According to the composition of the austenitic stainless steel according to the present invention, see Table 1. Electric furnace + AOD + LF is used for smelting, and the slagging is carried out after the reduction of the refining station. %; After secondary slagging, add 3-10Kg of 70% pure TiFe powder per ton of molten steel to the tapping ladle; add low-carbon synthetic slag for slag replacement after tapping, and add 70 % purity TiFe wire 40-250Kg, the Ti content is controlled at 0.10-0.25%, and after stirring, it is cast into a 200mm thick continuous casting slab, and the nitrogen content of the finished product after casting is controlled below 0.020%; after the continuous casting slab is heated and rolled Pickling to get 3-60mm thick plate;

[0037] For comparison, EAF+AOD+LF smelting is also carried out on the current general-purpose 304L (comparative example 1). Obviously, if its Md30 is obviously higher than the composition of the present invention, a furnace o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com