Continuous anodic electrolytic cell for preparing high performance aluminum alloy

An anode electrolysis and aluminum alloy technology, which is applied in the field of high-performance aluminum alloy preparation equipment, can solve the problems of complex operation, difficult control, and poor quality of high-performance aluminum alloy, and achieve simple production process, low control difficulty, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

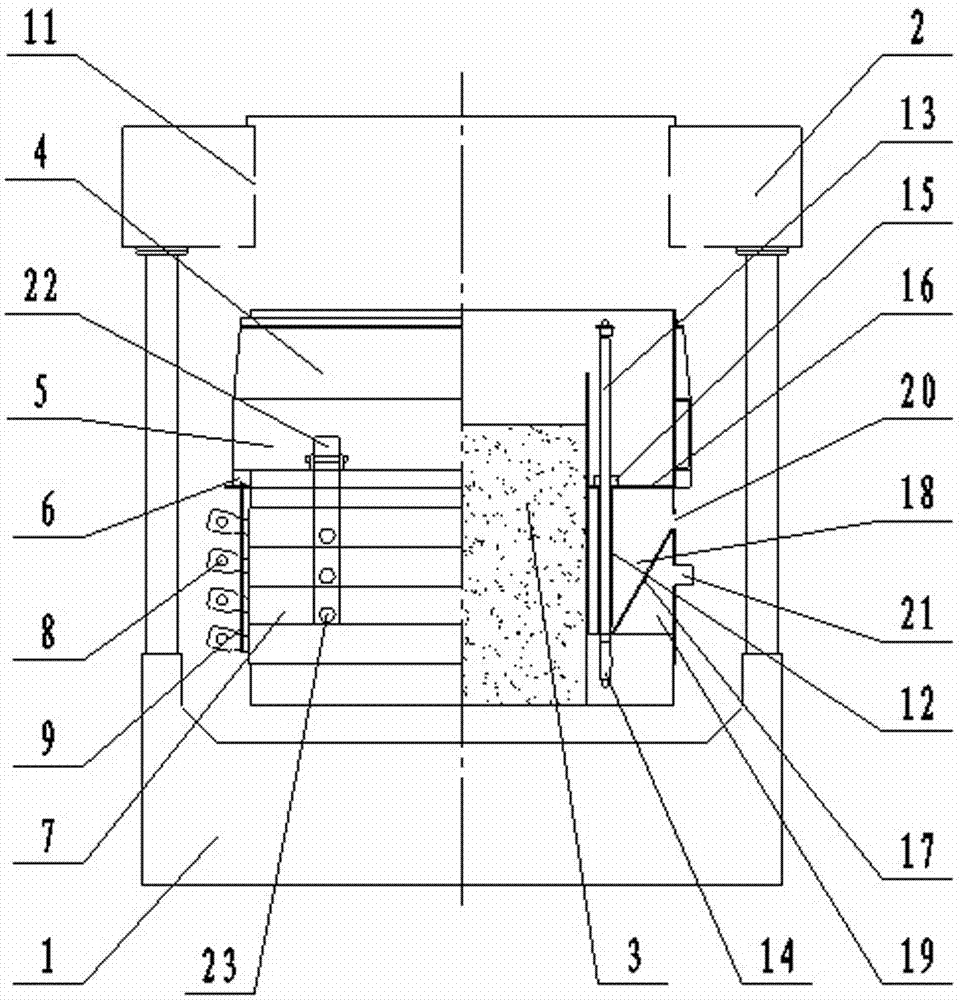

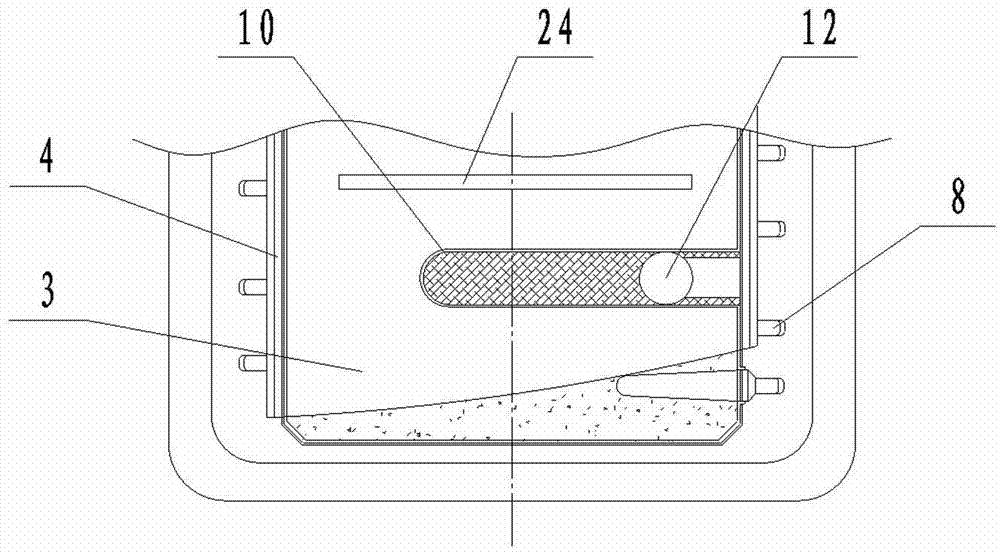

[0017] The continuous anode electrolytic cell for the preparation of high-performance aluminum alloys includes a continuous anode device, a cathode device 1 and a metal platform 2 located above the continuous anode device. The number of continuous anode devices is one or more. A single continuous anode device is composed of the surrounding side walls The anode body 3 covered with aluminum foil or aluminum plate is composed of an anode box body. The upper part of the anode box body is provided with a sleeve-shaped metal frame 4 that is sleeved around the anode body 3. The outer wall of the metal frame 4 is provided with a load-bearing fastening ring 5, which is tightly loaded. A load-bearing hook connector 6 is fixed around the lower side of the fixing ring 5. A number of sealing cover plate frames 7 arranged up and down are arranged on the lower part of the anode box body. The sealing cover plate frame 7 is composed of a number of sealing covers close to the side walls of the ano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com