Wadding flake with function of intellectualized thermoregulation and preparation method thereof

A flake and functional technology, which is applied in the field of flakes with intelligent temperature regulation function and its preparation, can solve the problems of unfavorable practical promotion and use, unable to cover fiber types, complicated manufacturing process, etc. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

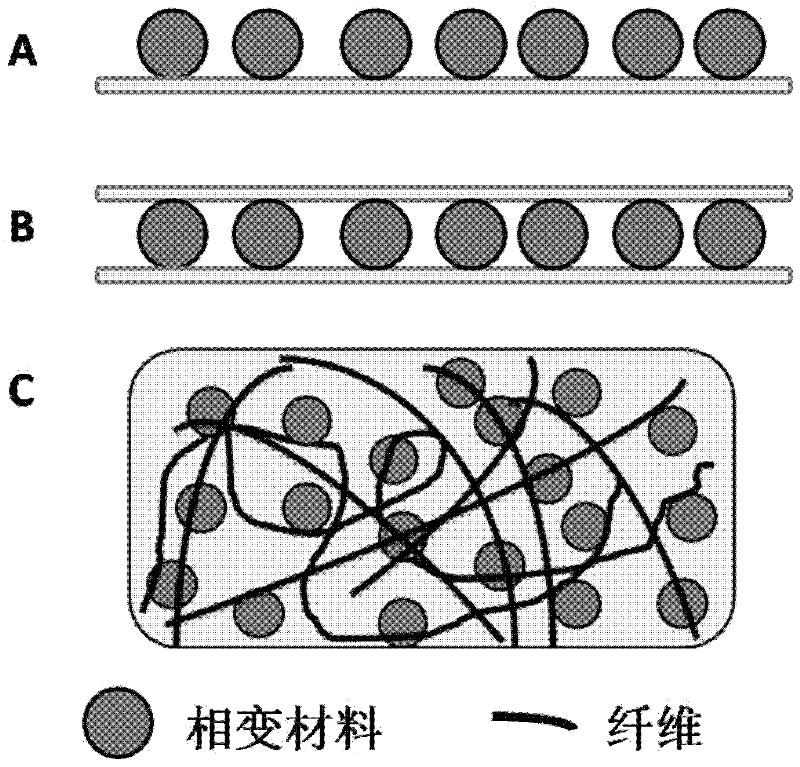

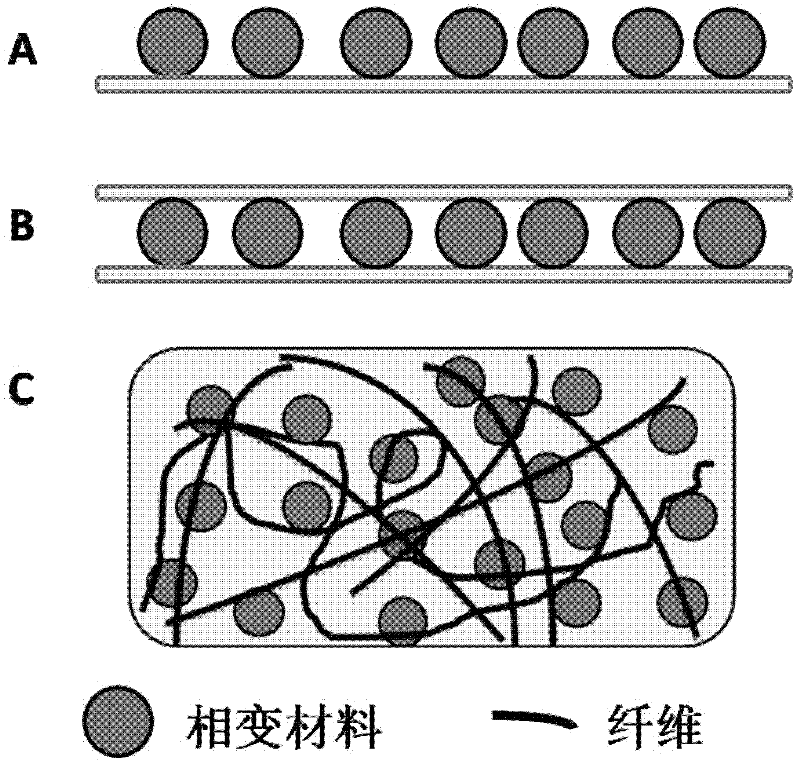

Embodiment 1

[0037] 200g phase-change microcapsule material dispersion (the dispersion is an emulsion, that is, the phase-change microcapsules are dispersed in water or other solvents, the main component is that the capsule core is phase-change alkane, and the shell layer is urea-formaldehyde resin, or other materials such as polyurethane) Polymer, the particle size is controlled between 100 nanometers and 1000 microns, the preparation method can refer to the article Journal of Applied Polymer Science, 2005, 97: 390; Colloidal and Polymer Science, 280: 290), and 800g distilled water, 1.5g polypropylene Sodium and 2 g of dialkyl sulfosuccinate were mixed well until no solid matter was evident. Use a commercially available pump spray bottle to evenly spray the dispersion system obtained above onto the flakes made by traditional techniques. In this example, commercially available cashmere flakes and commercially available flakes are sprayed. , the amount of spraying is 20% of the mass of the ...

Embodiment 2

[0040] The mass ratio of each fiber raw material is as follows:

[0041] Down (duck or goose down,) 30%, polyester fiber 62%, bonding fiber (polypropylene fiber) 8%.

[0042] The phase change material emulsion and adhesive (formaldehyde-free environmental protection adhesive, choose Yihui Chemical PUD water-based polyurethane composite adhesive, or Dongfang Rohm and Haas ST954 water-based adhesive, etc.) are uniformly mixed according to the mass ratio of 9:1. mix.

[0043] Wherein, phase change material emulsion formulation (mass parts) is:

[0044] 570 parts phase change paraffin

[0045] 200 parts of ammonia solution of sz25010 (polyscope) (solid content 15%)

[0046] 230 parts deionized water

[0047] The raw material fibers are mixed, the mixed fibers are carded, the web is laid, and after the web is formed, the web is drawn. The two sides of the fiber web are sprayed with the mixed solution of the phase change material and the adhesive, and the spraying amount is 15%...

Embodiment 3

[0051] The mass ratio of each fiber raw material is as follows:

[0052] Down (duck or goose down,) 30%, polyester fiber 62%, bonding fiber (polypropylene fiber) 8%.

[0053] The raw material fibers are mixed, the mixed fibers are carded, the web is laid, and after the web is formed, the web is drawn. Spray the adhesive on both sides of the fiber web (environmentally friendly adhesive that does not contain formaldehyde, choose Yihui Chemical PUD water-based polyurethane composite adhesive, or Dongfang Rohm and Haas ST954 water-based adhesive, etc.), the spraying amount is the fiber web quality 10% of.

[0054] The phase-change material powder (this powder is the microcapsule powder with lauryl alcohol as the capsule core and the urea-formaldehyde resin as the shell material) is obtained by the method described in the following documents, and then the obtained powder is filtered, and the particle size of the powder is In the range of 2 to 50 microns, the preparation method re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com