Blanking port integrated blanking device for biomass fuel circulating fluidized bed boiler

A technology of circulating fluidized bed and biomass fuel, which is applied in the direction of fluidized bed combustion equipment, fuel burned in a molten state, and combustion methods, etc., and can solve the problem of discounting the seeding effect of the seeding air nozzle 104a, increasing fuel friction, and falling The fire and other problems of the material tube can achieve the effect of facilitating flow and spreading, preventing erosion and wear, and evenly distributing air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

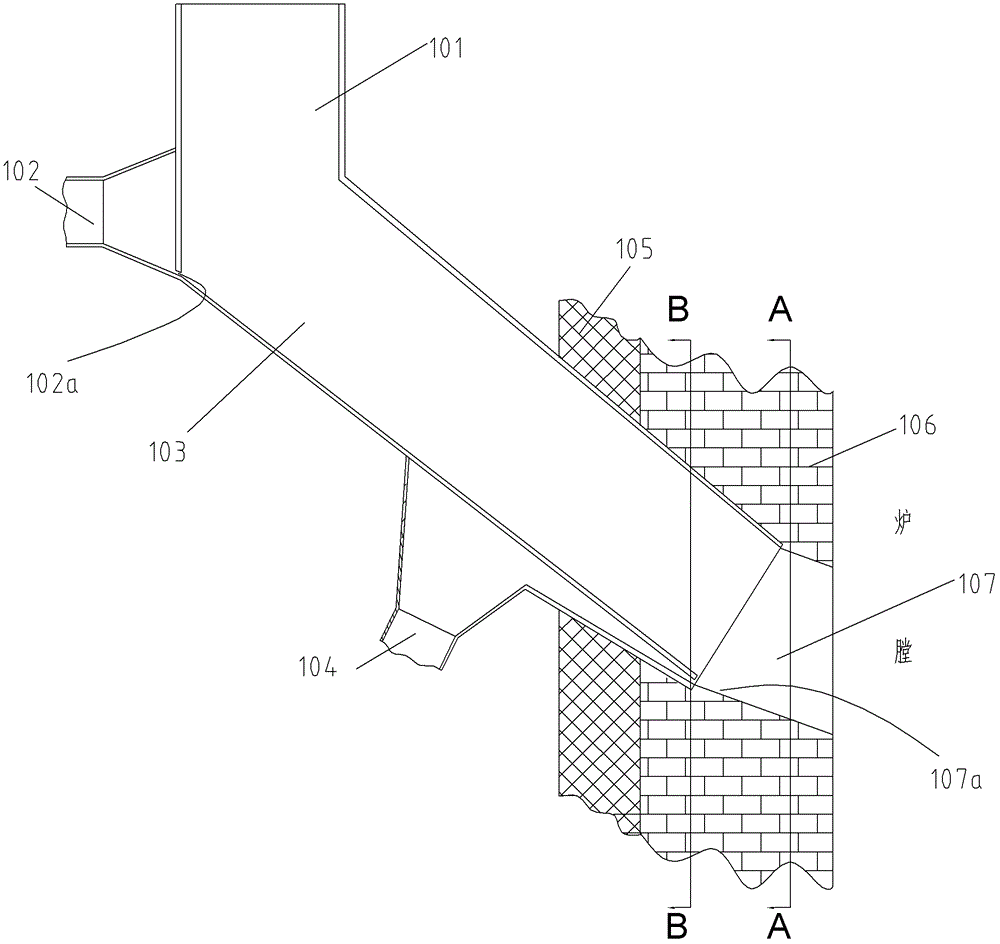

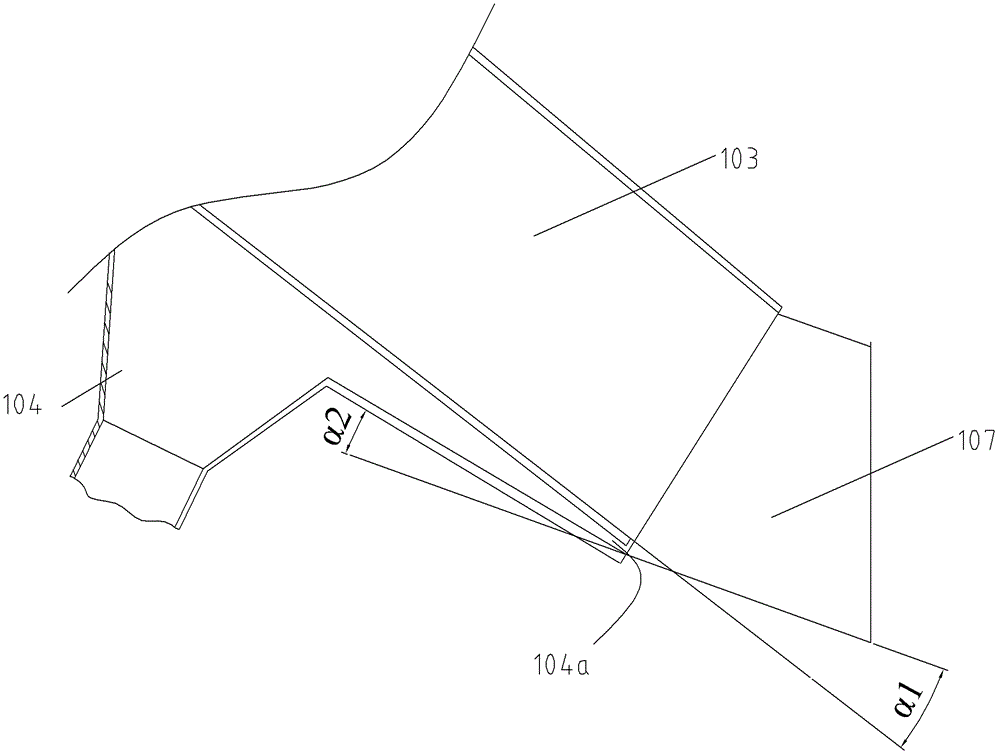

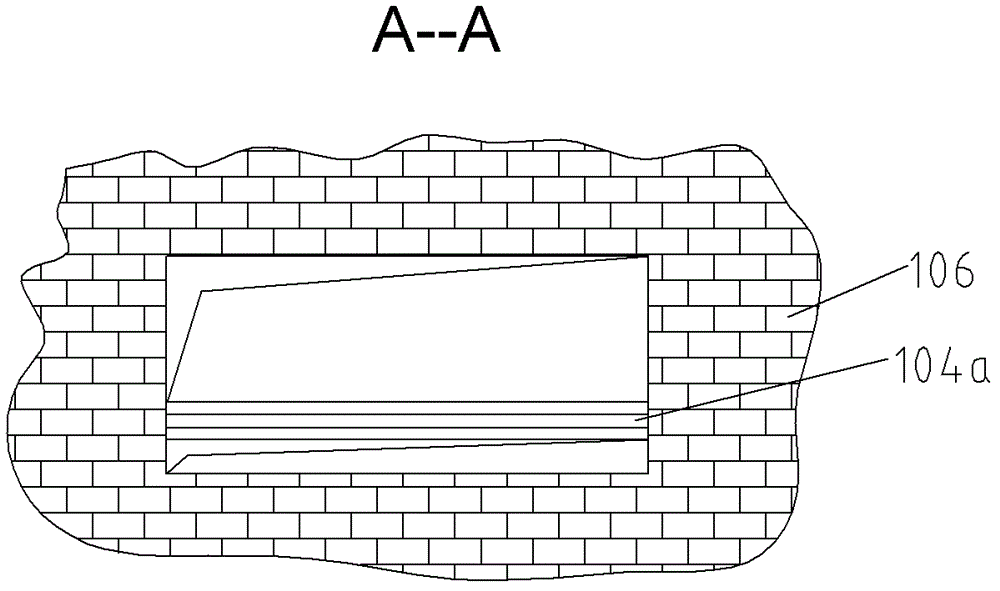

[0040] Such as Figure 5 to Figure 7 The integrated blanking device for the blanking port of a biomass fuel circulating fluidized bed boiler is shown, which includes an interface pipe 1 for connecting the blanking pipe 8 of the feeding system in front of the furnace, and a pipe for introducing fuel into the furnace of the boiler. The guide pipe 3, the disturbance air pipe 2 and the feeding air pipe 4, the material of the interface pipe 1 and the guide pipe 3 are all high-temperature wear-resistant stainless steel, and the upper end of the interface pipe 1 is connected to the feeding pipe 8 of the feeding system in front of the furnace, and the interface The lower end of the pipe 1 is connected with the diversion pipe 3, the interface pipe 1 is arranged vertically, and the diversion pipe 3 is arranged obliquely downward. During installation, a sealing box 7 is installed outside the boiler furnace wall 5, and the disturbance air pipe 2 and the broadcasting air pipe 4 The rear en...

Embodiment 2

[0052] Example two of an integrated blanking device for a biomass fuel circulating fluidized bed boiler blanking port of the present invention Figure 8 As shown, the difference from Embodiment 1 is that there is an included angle γ between the mouthpiece 1 and the vertical surface, and the included angle γ is 30°, so as to adapt to the relationship between the feeding pipe 8 of the furnace front feeding system and the vertical direction. Existing 30° included angle.

[0053] In this embodiment, the included angle γ between the mouthpiece 1 and the vertical surface can also take a value between 0° and 30°, so as to adapt to the gap between the feeding pipe in front of the furnace and the vertical direction. The included angle is convenient for targeted technical transformation of the existing biomass fuel circulating fluidized bed boiler blanking device.

[0054] In this embodiment, the diameter ratio D1 : D2 : D3 of the spray holes in the upper, middle and lower layers of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com