Groove type condensation solar heat collecting tube with compensation sealing structure and assembling process of groove type condensation solar heat collecting tube

A technology of concentrating solar energy and sealing structure, which is applied in the field of solar thermal utilization, which can solve the problems of high welding quality requirements, expansion stress and welding stress, and difficulty in non-destructive testing at transitional parts, so as to facilitate weld surface detection, welding Few defects, prevent heat loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

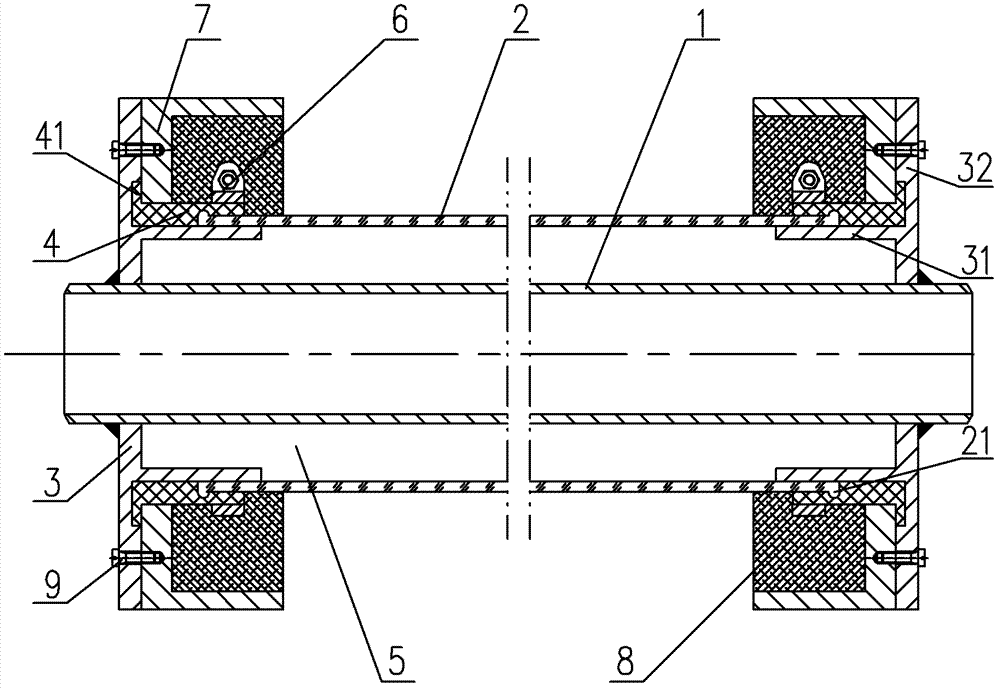

[0041] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0042] Such as figure 1 The best embodiment of the trough-type concentrating solar heat collector tube with compensating sealing structure of the present invention shown, it has coating stainless steel tube 1, coating stainless steel tube 1 outer jacket is equipped with coating borosilicate glass tube 2, coating Both ends of the stainless steel tube 1 are fitted with a stainless steel head 3, and the outer wall of the coated stainless steel tube 1 is in sealing connection with the stainless steel head 3; the coated silicon borosilicate glass tube 2 is in sliding connection with the stainless steel head 3; High-temperature silicone rubber compensation sleeve 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com