Circulating cooling water low-temperature exhaust heat drying bed for large-scale power station

A technology of circulating cooling water and drying bed, which is applied in the direction of heating to dry solid materials, drying solid materials, drying, etc., can solve problems such as reducing drying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

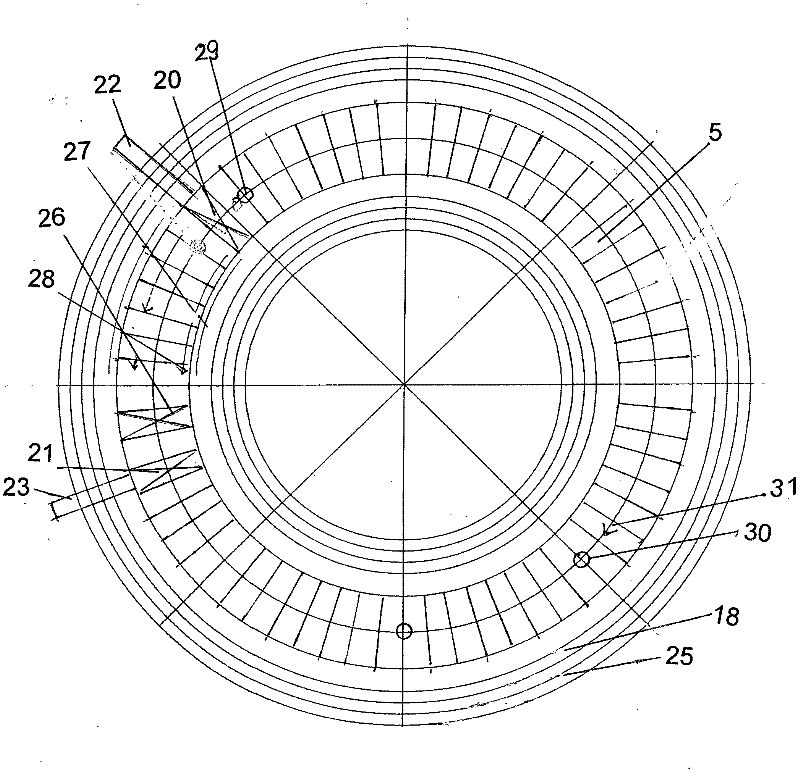

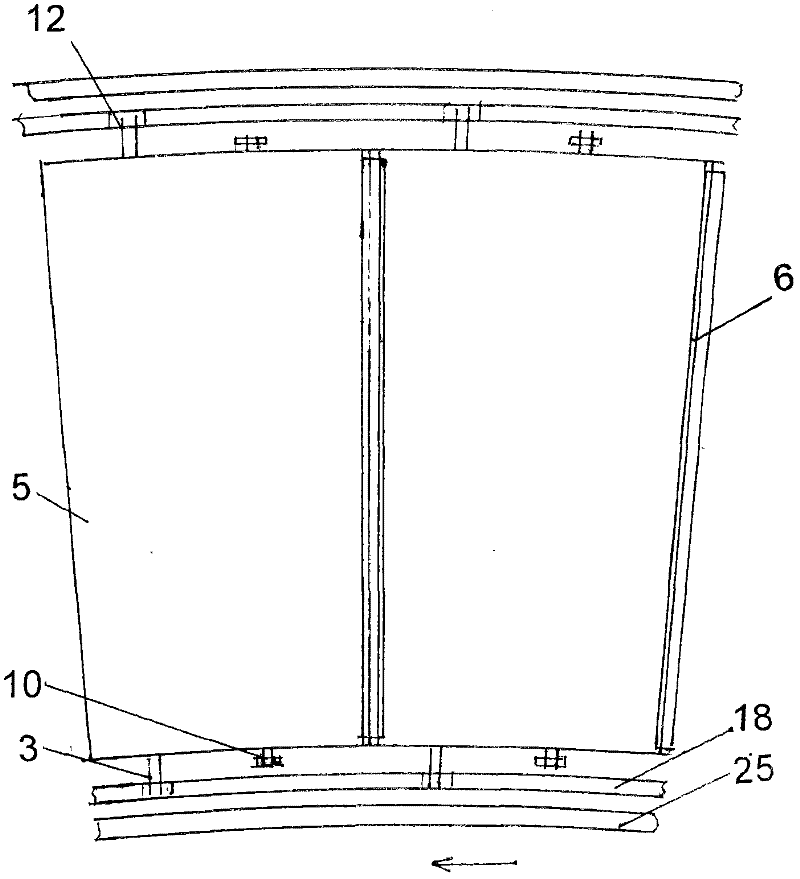

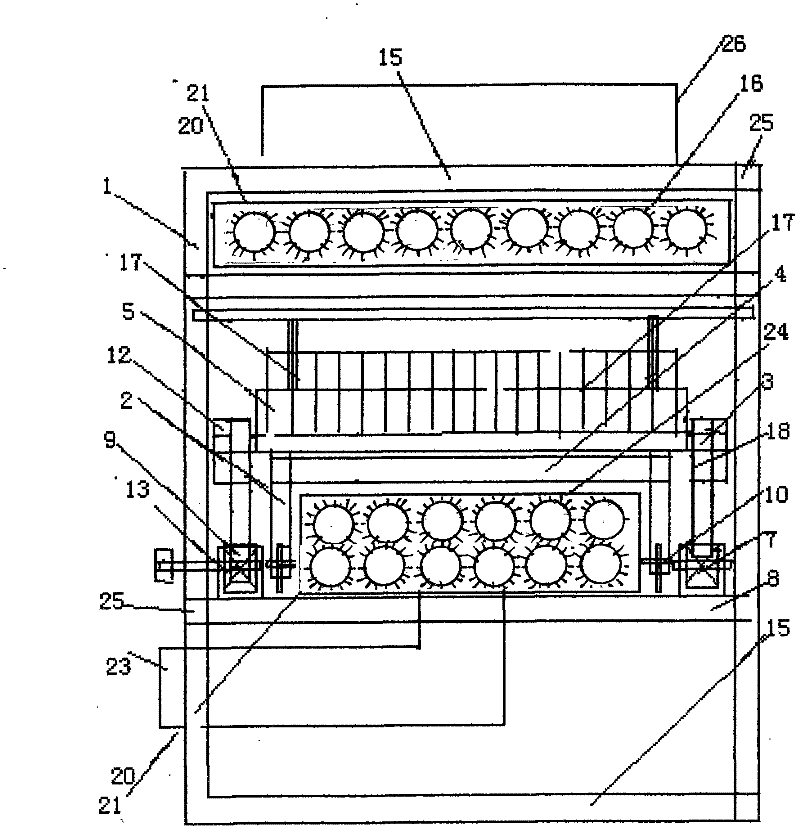

[0010] The specific working principle of the large-scale circulating cooling water low-temperature waste heat drying bed will be further explained below in conjunction with the accompanying drawings. The cooling residual hot water is divided into the feather tubes of the tube group 16 and the tube group 24 through the water inlet 23 respectively through the upper and lower two sets of tube-sheet headers 21, and dissipates heat into the bed through the feather fins during the flow. The material to be dried is sent into the hopper 5 by the feeding device. The material bed runs in the same direction as the residual hot water, and the material absorbs the heat emitted by the fins along the way. Crushing, it can stir and stir common materials and accelerate drying without leaving dead ends. It can be suspended when not in use, and the hopper 5 can be replaced according to the actual drying materials. The cold air enters the bed chamber in different directions from the inlet 29, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com