Non-contact micro-vibration measuring system based on non-equilibrium Michelson fiber-optic interferometer

A fiber optic interferometer, Michelson's technology, applied in measurement devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problem of limiting the application range of fiber Michelson interferometer measurement, the influence of light intensity, and the inability to accurately measure signals and Vibration direction and other issues to achieve good response, low cost, good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

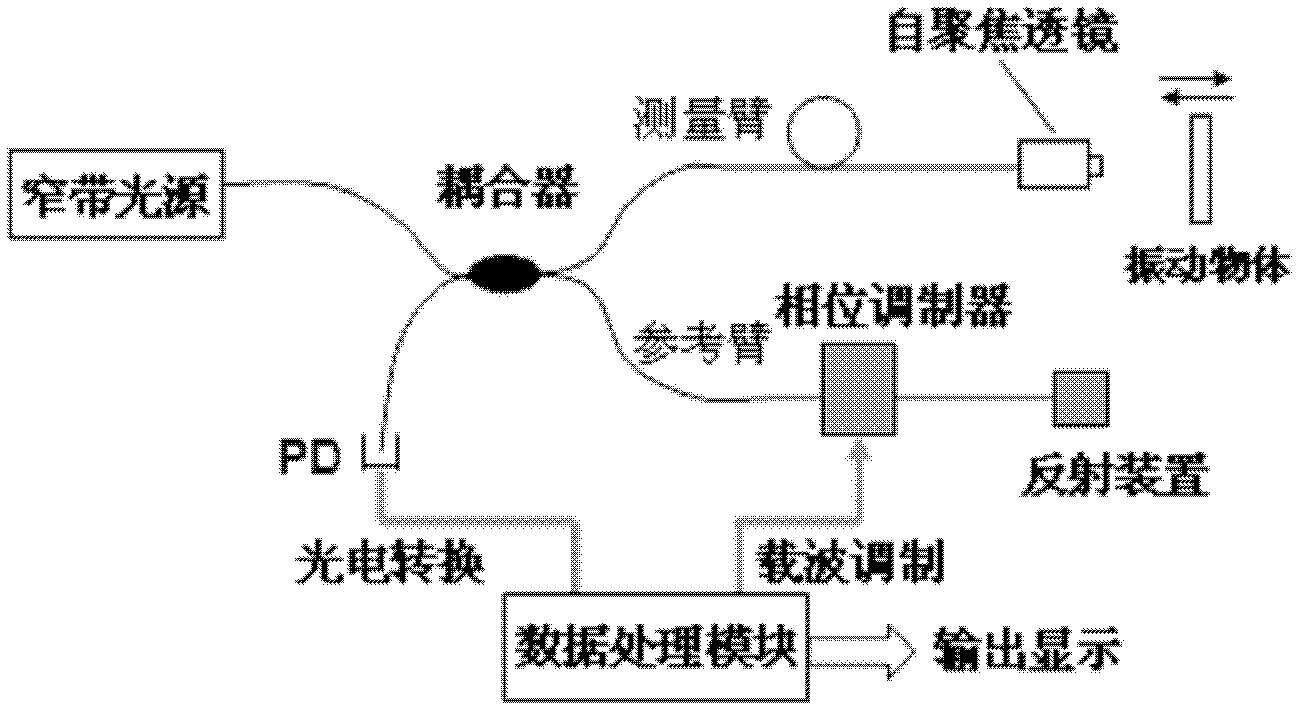

[0015] Such as figure 1 As shown, the distributed feedback laser (DFB) with a central wavelength of 1554.71nm emits laser light and is divided into two paths through a single-mode fiber 3dB coupler, and one path passes through the fiber optic of the measuring arm to the fiber optic self-focusing lens, and the self-focusing lens is adjusted to emit parallel light for vertical irradiation to the surface of the measured object, the parallel light is reflected by the self-focusing lens, coupled to the optical fiber of the measuring arm and returned to the coupler, and the other path passes through the optical fiber of the reference arm to the end reflection device and returns to the coupler along the optical fiber of the reference arm. Interference occurs in the coupler and is output from the coupler, which is then conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com