Photoetching lamp optical system

An illumination optical system and lithography technology, applied in microlithography exposure equipment, optics, optical components, etc., can solve the problems of high price and high cost of microlens arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

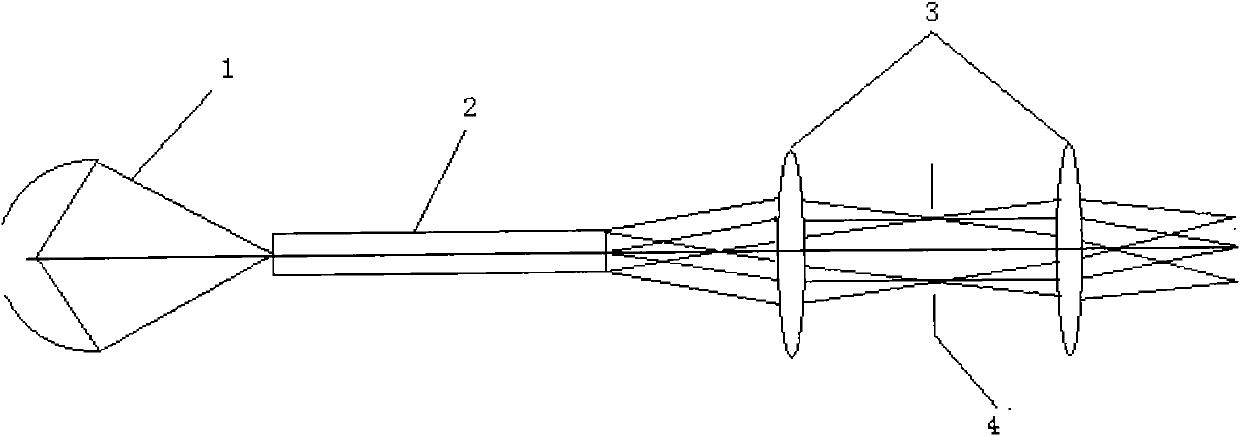

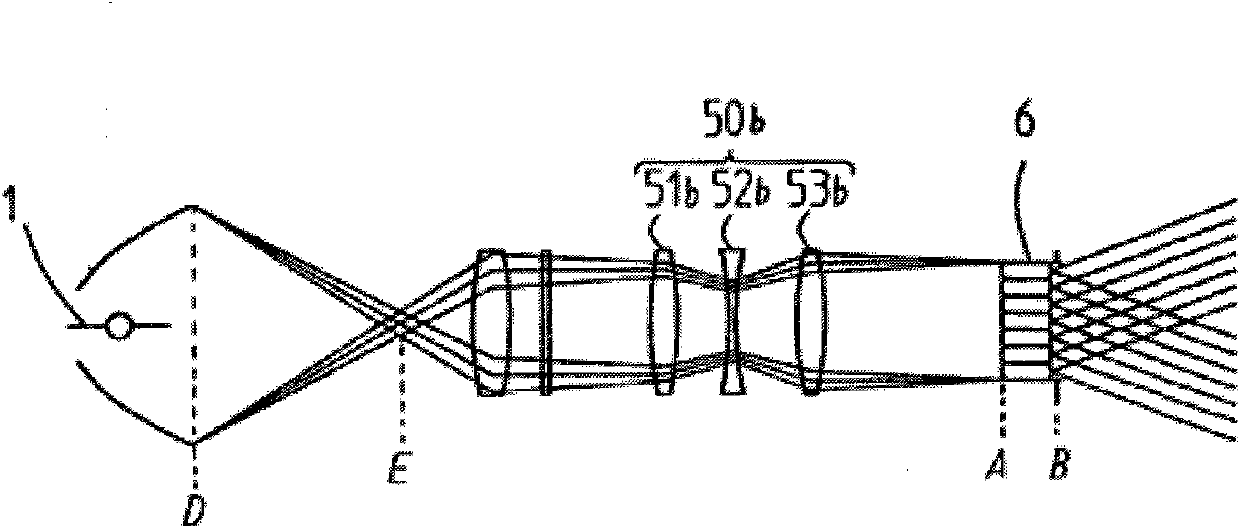

[0023] A specific example of the present invention is Figure 4 shown. The light emitted by the light source 100 is converged by the ellipsoidal reflector and irradiated on the uniformity enhancing element fly-eye lens 200. After passing through the fly-eye lens 200, the light beam enters the incident end surface 300a of the integrator rod 300, and the light beam is totally reflected in the integrator rod 300 for many times. Uniform illumination is formed on the exit end face 300b of the integrating rod. After being enlarged by the relay lens 400, the exit end face 300b of the integrating rod is imaged on the mask plate 600 through the aperture stop 500, and the required light with a certain numerical aperture, Size, uniformity of illumination field of view.

[0024] In this embodiment, the fly-eye lens 200 used by the uniformity enhancing element, such as Figure 5 shown.

no. 2 example

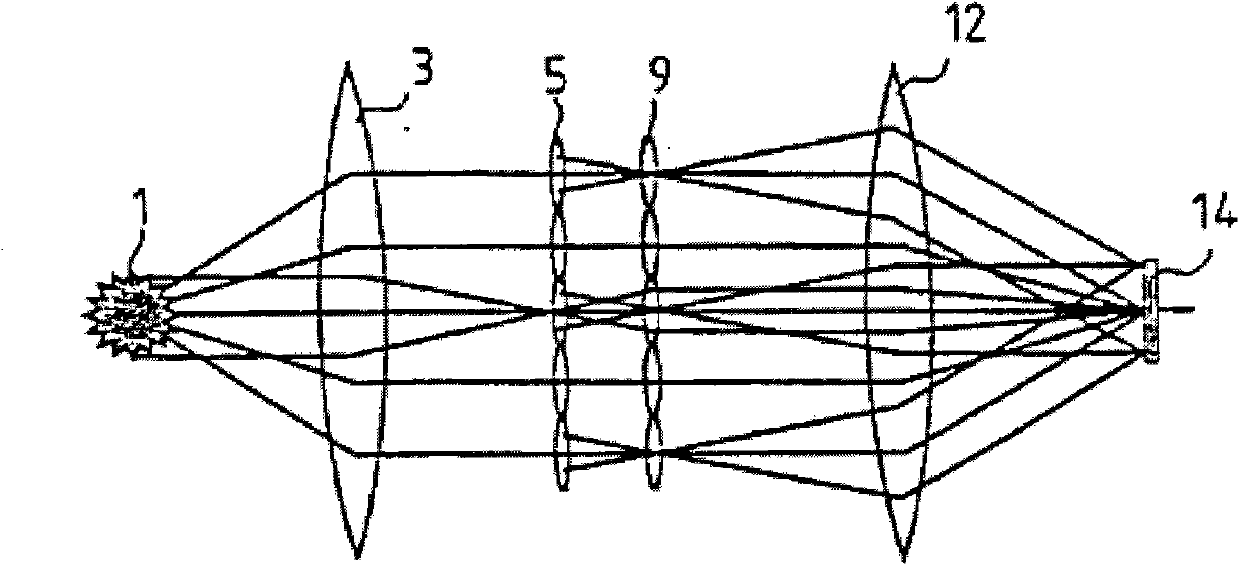

[0026] Another specific embodiment of the present invention is Figure 6 shown. The light emitted by the mercury lamp is converged by the ellipsoid reflector and passes through the coupling lens 700. The coupling lens 700 can change the numerical aperture of the light source 100 or keep the numerical aperture of the light source 100 unchanged. On the element microlens array 800, the light beam enters the incident end surface 300a of the integrator rod 300 through the microlens array 800, and after the light beam is totally reflected in the integrating rod 300 for many times, uniform illumination is formed on the exit end surface 300b of the integrating rod, and the exit end surface 300b of the integrating rod After being magnified by the relay lens 400 , the image is imaged on the mask plate 600 , and a required illumination field of view with a certain numerical aperture, size and uniformity is formed on the mask plate 600 .

[0027] In this embodiment, the uniformity enhanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com