Temperature control system for reflux welder

A technology of temperature control system and reflow soldering machine, which is applied in the direction of temperature control, control/regulation system, non-electric variable control, etc. It can solve the problems of temperature control lag, hysteresis, difficulty in satisfying overshoot and undershoot, and achieve temperature fluctuation. Small size, rapid temperature rise, time-saving and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

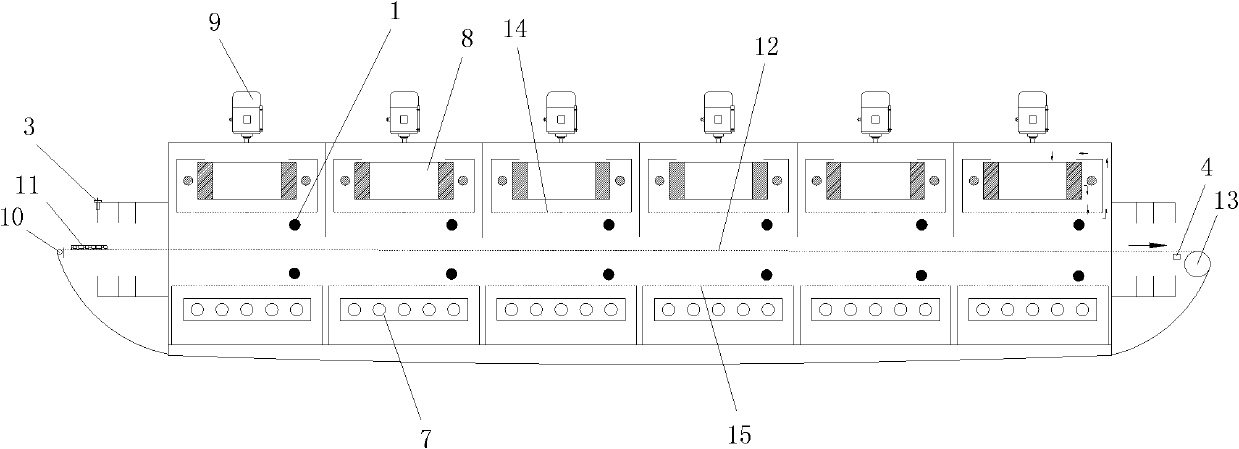

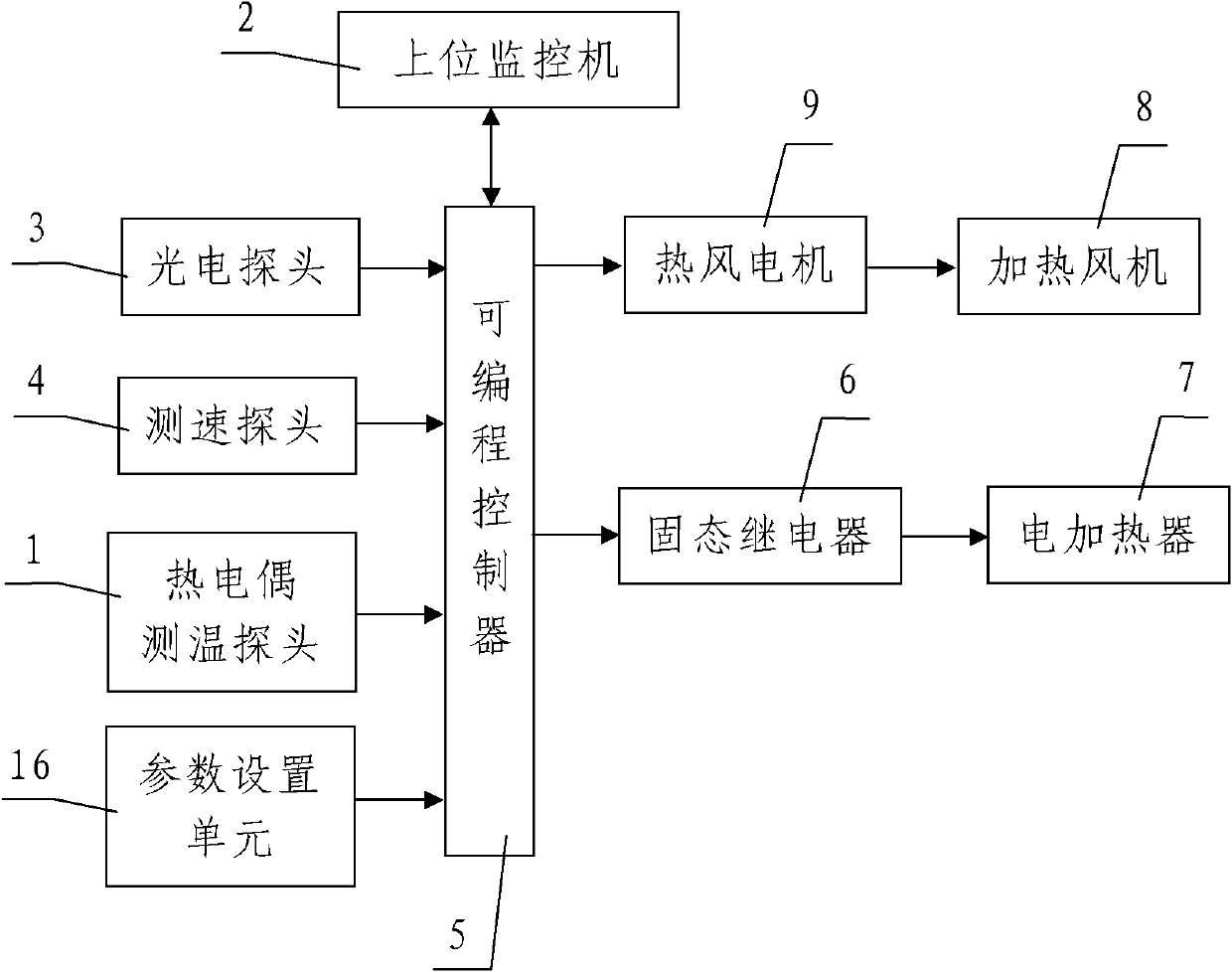

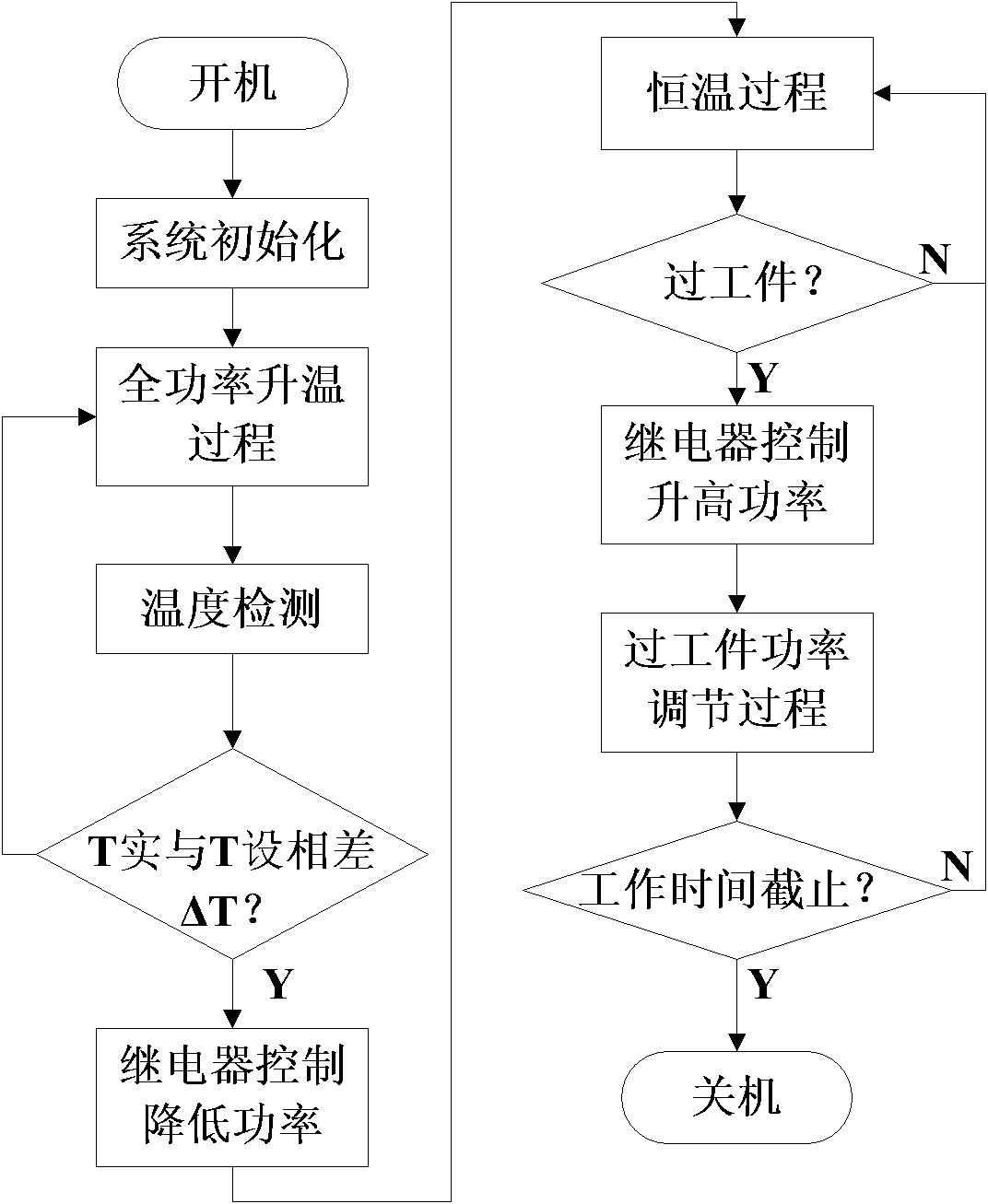

[0029] Such as figure 1 , figure 2 As shown, the present invention includes a programmable controller 5, a parameter setting unit 16 connected with the programmable controller 5, a plurality of temperature detection units for real-time detection of the temperature in multiple temperature zones in the reflow soldering machine, and The upper monitoring machine 2 connected to the programmable controller 5, the plurality of temperature detection units are connected to the programmable controller 5, and the plurality of temperature detection units are respectively arranged in a plurality of the temperature zones, and the programmable The controller 5 is connected to a plurality of electric heaters 7 and a plurality of heating fans 8 respectively arranged in a plurality of temperature zones in the reflow soldering machine, and a plurality of the electric heaters 7 and a plurality of heating fans 8 All are controlled by the programmable controller 5 , the plurality of heating fans ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com