Capacitor structure and manufacturing method thereof

A technology of capacitor structure and manufacturing method, applied in capacitors, electrolytic capacitors, solid electrolytic capacitors, etc., can solve problems such as high-cost heat treatment equipment, increase construction costs, etc., and achieve the effect of improving conductivity and reducing heat treatment temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

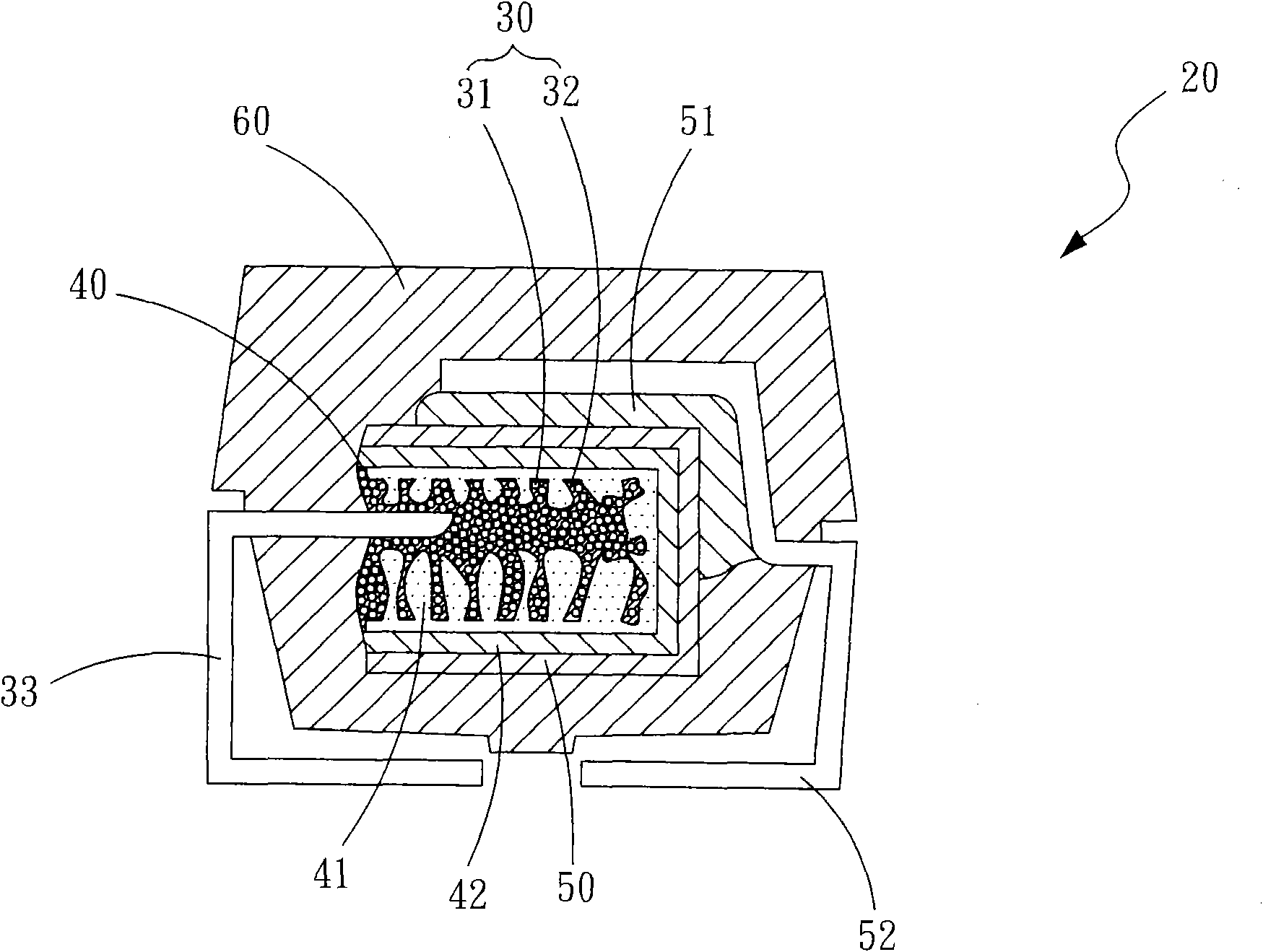

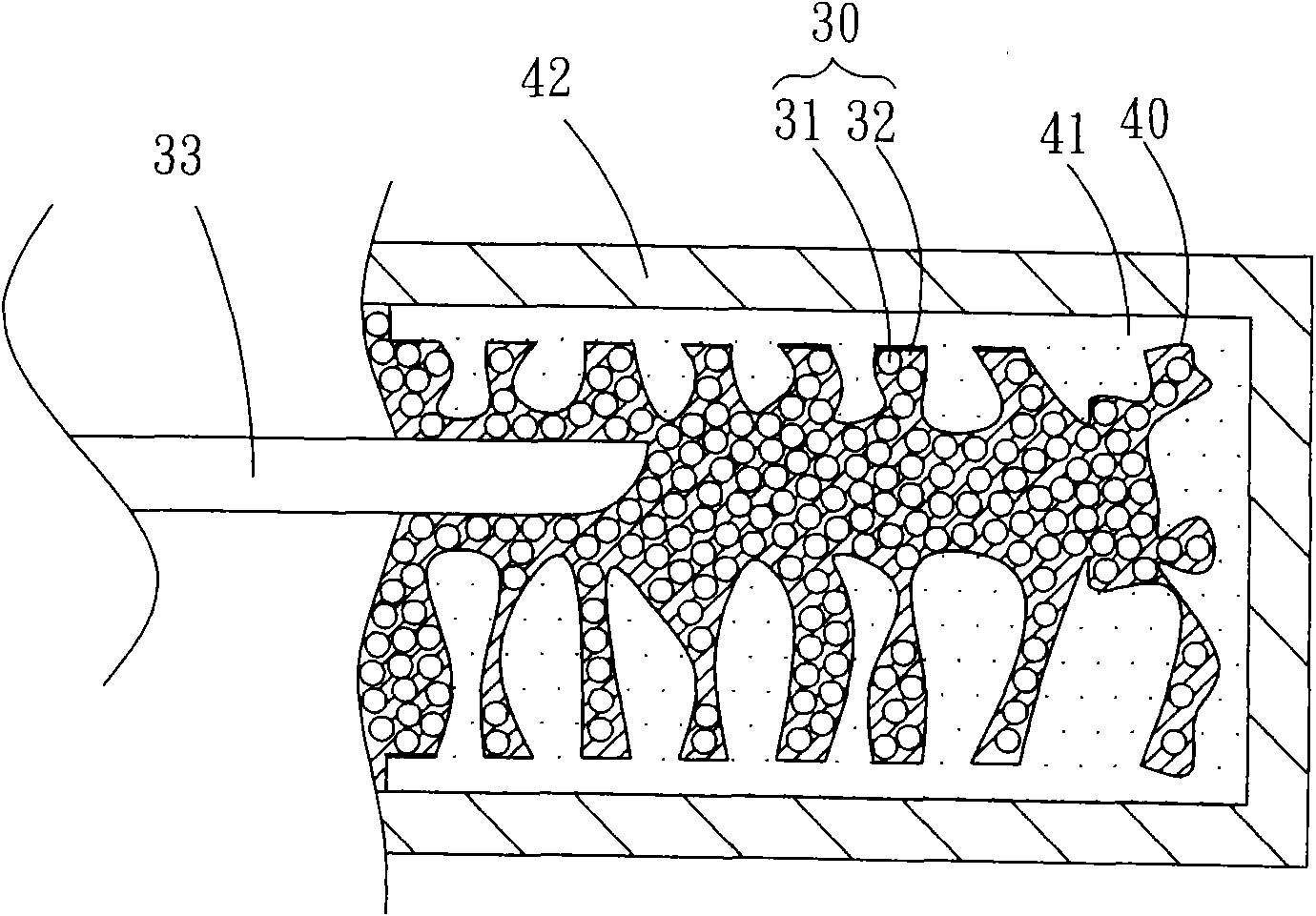

[0051] see figure 2Shown is a schematic cross-sectional view of the capacitor structure of the present invention. The capacitor structure 20 includes: a first conductor layer 30 having a first metal material 31 and a second metal material 32, and the first conductor layer 30 is covered with On the surface of a first external terminal 33, a gap is formed between the first metal material 31, and the second metal material 32 is disposed at the gap position and formed on the surface of the first external terminal 33, and the first metal material 32 is formed on the surface of the first external terminal 33. A dielectric layer 40 is formed on the metal material 31, and a solid electrolyte layer 41 and a graphite layer 42 are sequentially arranged on the dielectric layer 40. The graphit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com