Detection method of semiconductor device defect

A detection method, a semiconductor technology, applied in the direction of semiconductor/solid-state device testing/measurement, optical testing flaws/defects, etc., can solve problems such as yield decline, failure to remedy in time, semiconductor device defects, etc., to improve yield and quality , The effect of reducing the waste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The inventor's existing inspection process is usually after the semiconductor device is fabricated on the wafer, in the quality inspection stage or when the finished product is sent to the customer, the quality inspector or customer can determine the defects in the semiconductor device by conducting electrical tests on the finished product For example, the production of TEM test samples is usually after all semiconductor devices are fabricated on the wafer, and then the isolation structure is electrically tested. If any abnormality is found, the abnormality is located, and then cutting is performed. Determine if the defect is at the location and the size of the defect. As a result, defects cannot be remedied in time, resulting in a decrease in yield, excessive waste, and great risks to the production of subsequent wafers in the mass-produced production line.

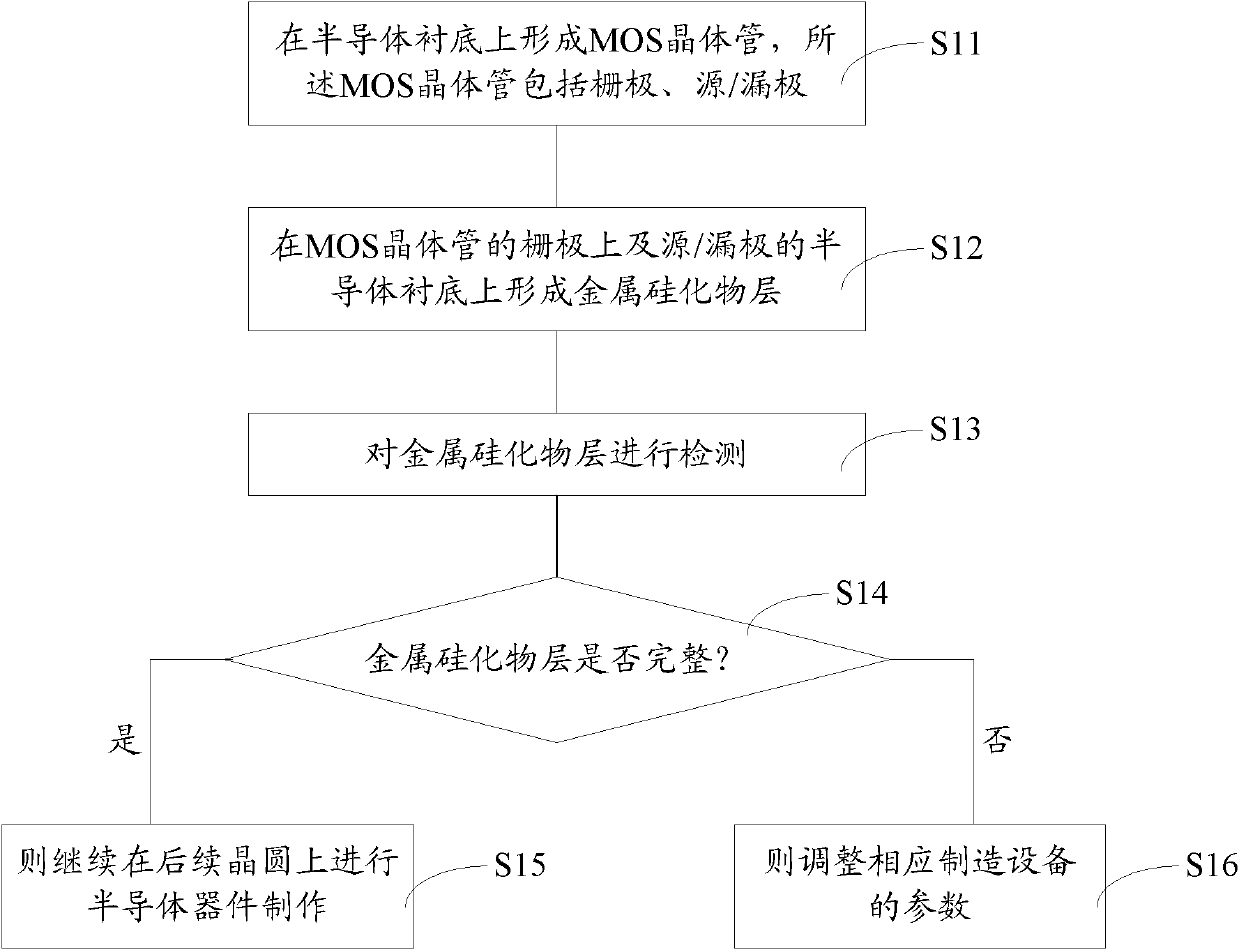

[0020] Therefore, the inventor found through research that if the semiconductor device is produced on the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com