PCM (phase change memory) and forming method thereof

A technology of phase-change memory and phase-change materials, which is applied in the field of phase-change memory and its formation, can solve the problems of poor film quality and poor doping concentration uniformity of buried layers, so as to improve device performance, improve film quality, and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

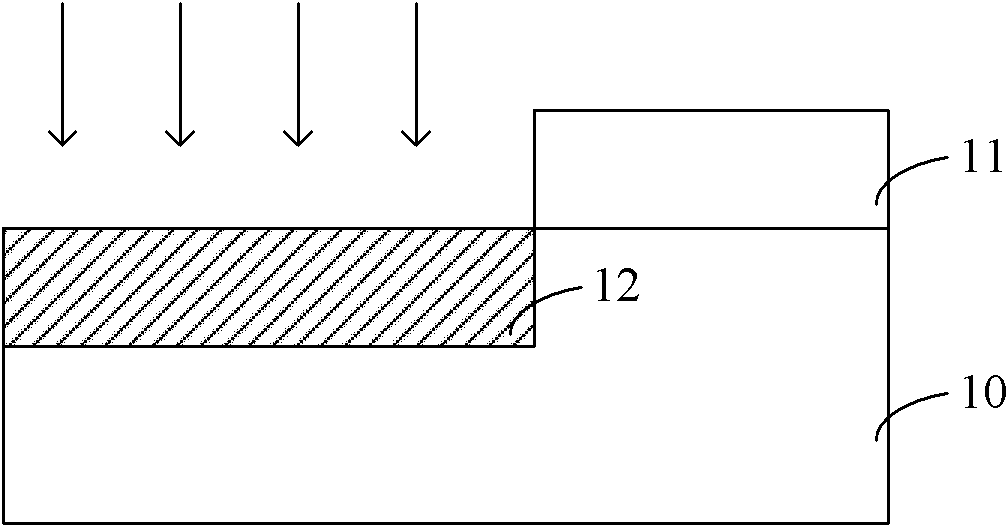

[0053] The existing technology uses ion implantation to form a buried layer in the semiconductor substrate as the word line of the phase change memory, but the process of ion implantation will cause damage to the surface of the semiconductor substrate, affecting the film quality of the PN junction subsequently formed on it. , resulting in degraded device performance.

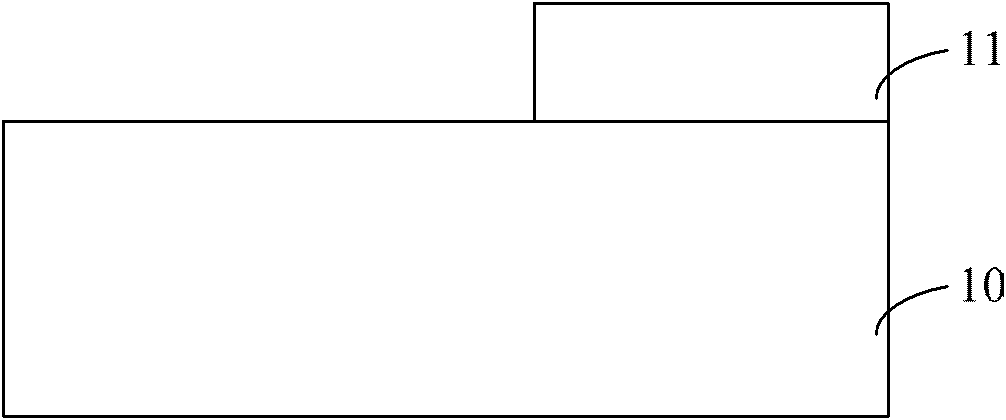

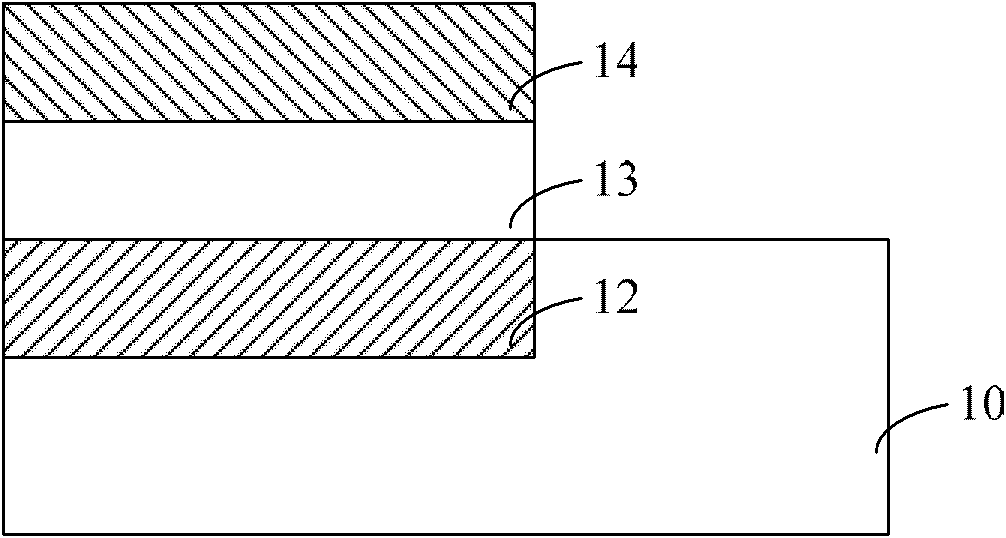

[0054]In the technical solution, a trench is formed on a semiconductor substrate, and then a first epitaxial layer is formed in the trench by epitaxial growth, and the first epitaxial layer is an N-type doped or P-type doped semiconductor material. The first epitaxial layer is used as the word line of the phase change memory, which is equivalent to the buried layer in the prior art. Since its formation process is formed by epitaxial growth, damage to the surface of the semiconductor substrate is avoided, which is conducive to improving the subsequent The film quality of other thin films formed on it, such as PN ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com