Method for improving the aqueous solubility of poorly-soluble substances

A water-soluble and insoluble technology, applied in the fields of botanical equipment and methods, chemicals for biological control, pharmaceutical formulations, etc. It has advantages and other issues, and achieves the effect of high industrial utilization value and excellent safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

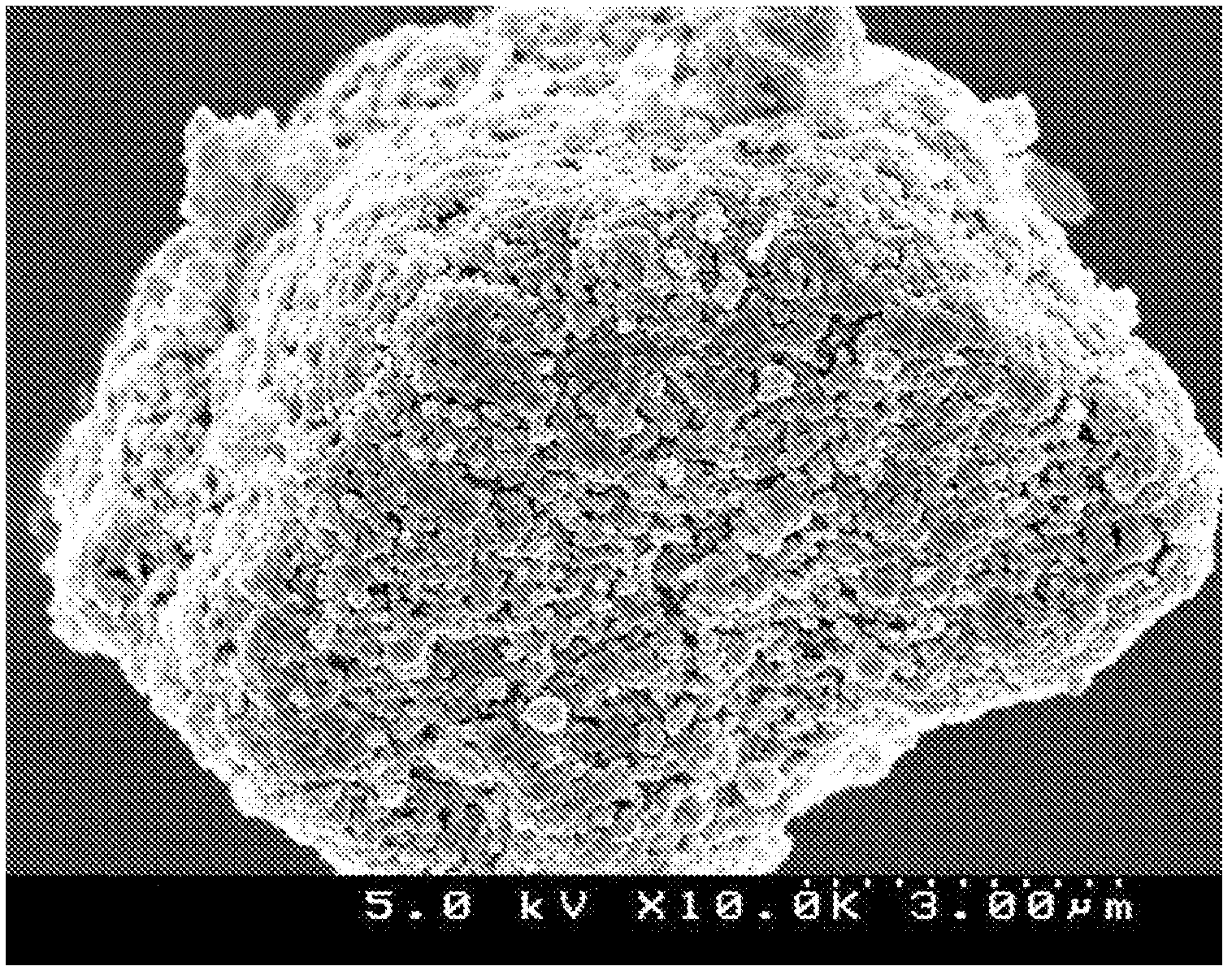

[0097] 1. [Preparation of coating agent]

[0098] A. [Preparation of Hydroxyapatite]

[0099] A 30% by weight aqueous solution of phosphoric acid was added dropwise to the stirred calcium hydroxide suspension until the Ca / P ratio reached 1.67. The gel-like substance thus produced was aged at room temperature for 1 day. Then, the gel-like substance was filtered with a glass filter, and the remaining substance was further dried in air at 100° C., and pulverized with a mixer to obtain hydroxyapatite.

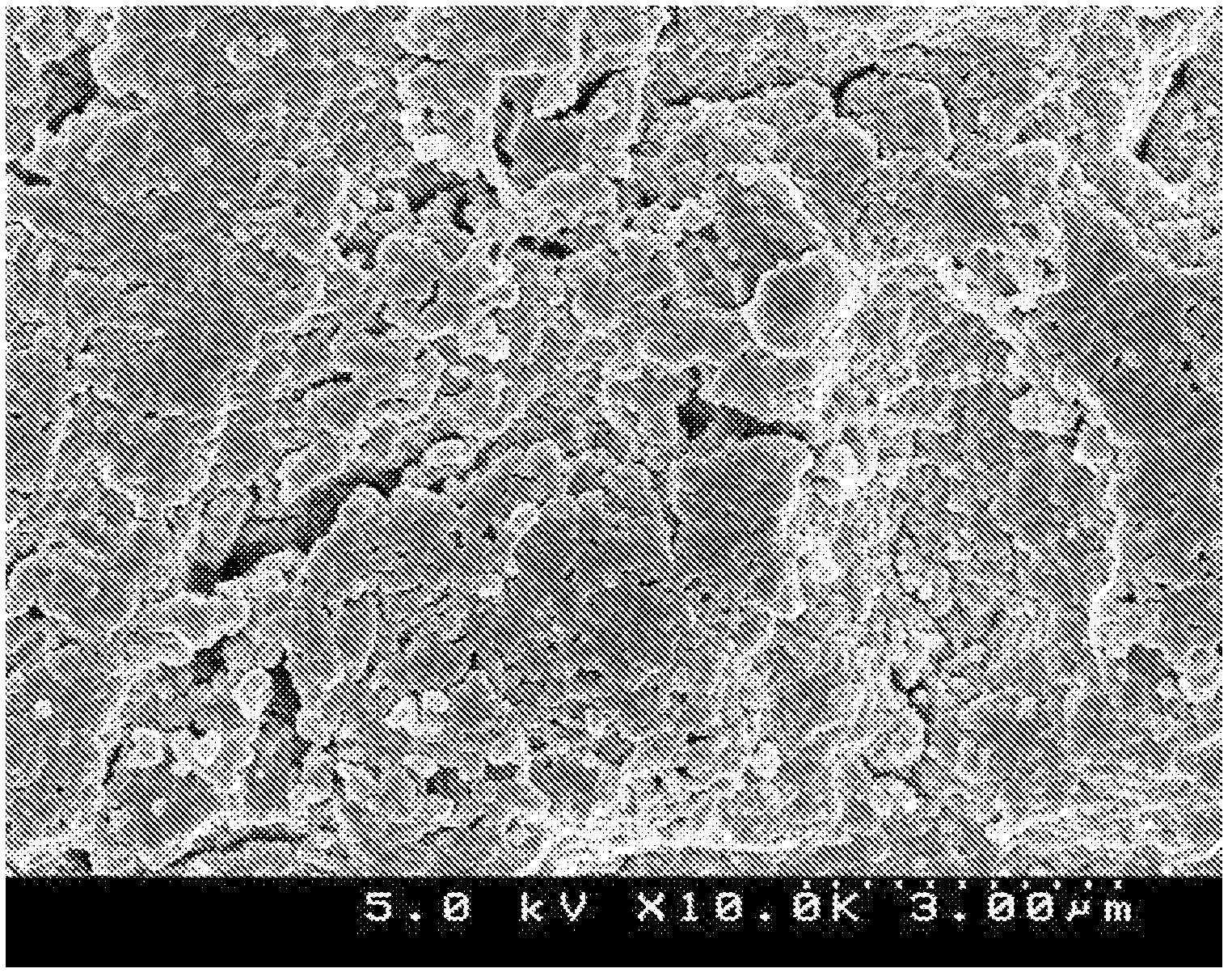

[0100] B. [Preparation of Hydroxyapatite Microparticles by Dry Process]

[0101] The hydroxyapatite obtained in the above [Preparation of hydroxyapatite] (hereinafter, simply referred to as "hydroxyapatite") was finely pulverized with a jet mill (manufactured by Co-Jet System α-mkII Co., Ltd. Seishin Co., Ltd.) , and obtained hydroxyapatite fine particles by a dry method.

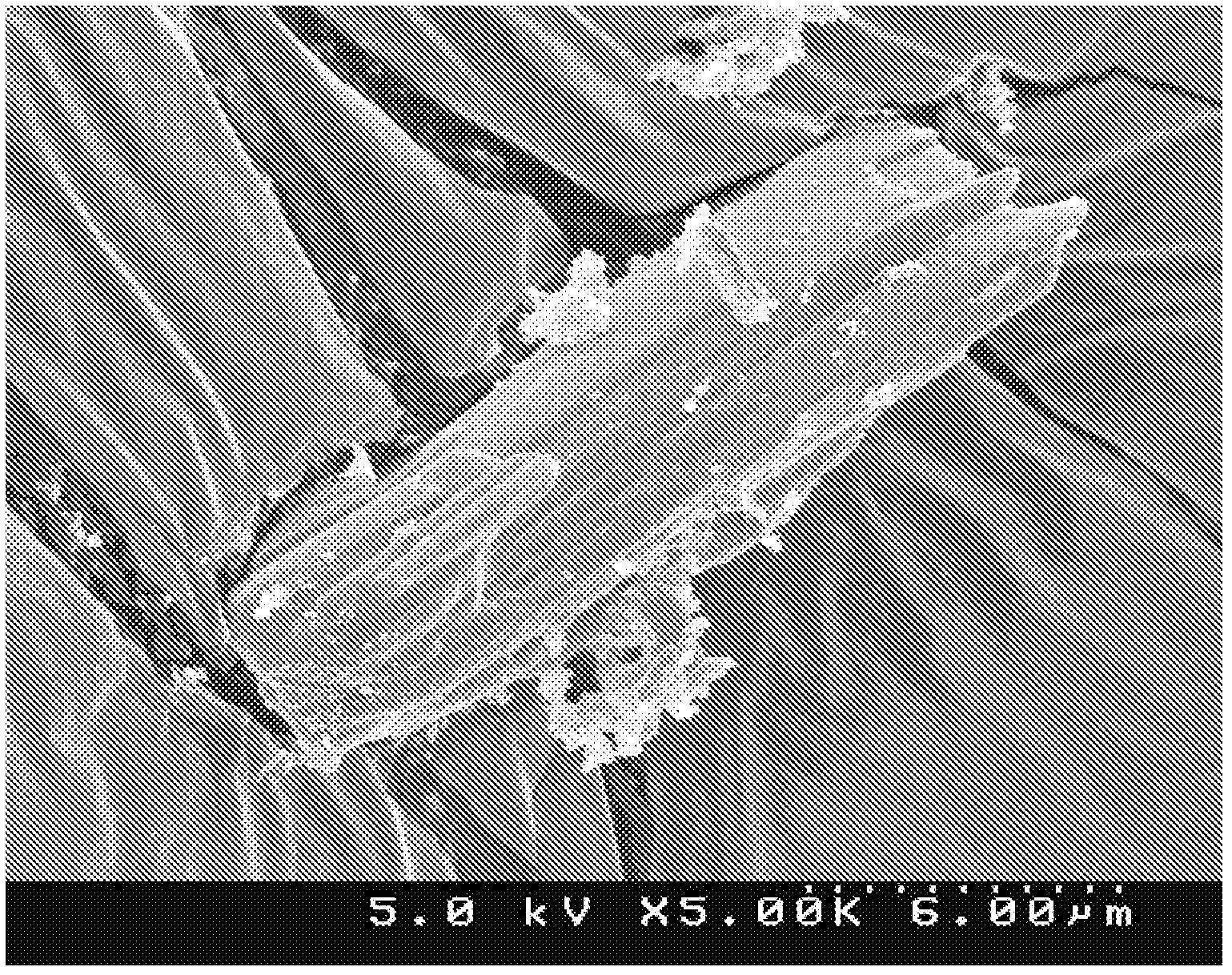

[0102] C. [Preparation of microparticles by wet method]

[0103] Hydroxyapatite, tricalcium phosphate, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com